Peculiar adsorption migration organic soil compound photocatalyst and mechanical mixing preparation method

A mechanical mixing and mobility technology, which is applied in the direction of catalyst activation/preparation, catalyst carrier, chemical instruments and methods, etc., achieves the effect of low price, simple equipment and avoiding secondary pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

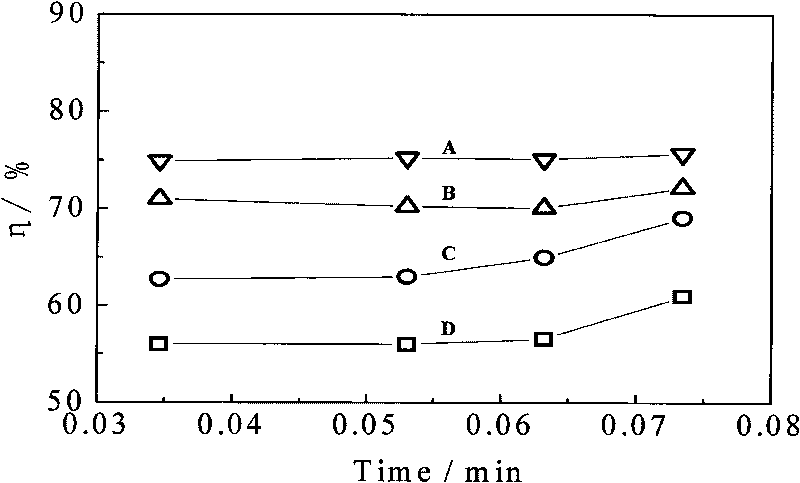

Image

Examples

preparation example Construction

[0018] The preparation principle of organic bentonite is to utilize the exchangeable cations (Ca 2+ 、Na + 、K + , Mg 2+ ) is exchanged with organic cations, the amount of cations added is 20% to 40% of the cation exchange capacity, and the surfactant used is dodecyltrimethylammonium bromide or cetyltrimethylammonium bromide. The organic soil modified by 20% CEC equivalent of dodecyltrimethylammonium bromide is referred to as 20 dodecyltrimethylammonium bromide, containing 80% of 20 dodecyltrimethylammonium bromide The composite material is referred to as 80-20 dodecyltrimethylammonium bromide, and other materials are referred to by analogy.

[0019] The mechanical grinding method combines the organic bentonite / primitive bentonite with the catalyst mainly due to electrostatic force, van der Waals force, etc., and the ultrasonic-centrifugal method can separate the two to achieve the purpose of recycling and reuse.

Embodiment 1

[0021] Put 5g of bentonite over 40 mesh and 0.3CEC equivalent of dodecyltrimethylammonium bromide into the beaker, add distilled water to keep the water-soil ratio at 8:1, stir and react at 50-80°C for 12h, and the stirring speed is 100r / min, then aged at 60°C for 12h, centrifuged and washed 3 times at a centrifugal speed of 3000r / min, 15min each time, dried at 70°C, and ground through a 40-mesh sieve. Add organic soil and commercial catalyst P25 with a mass ratio of 0.5:1 in a mortar, and mechanically grind for 10 minutes.

Embodiment 2

[0023] Put 20g of bentonite over 100 mesh and 0.4CEC equivalent of cetyltrimethylammonium bromide into the beaker, add distilled water to keep the water-to-soil ratio at 15:1, stir and react at 80°C for 24h, and the stirring speed is 200r / min , then aged at 90°C for 24 hours, centrifuged and washed 4 times at a centrifugal speed of 4000r / min for 15 minutes each time, dried at 80°C, and ground through a 100-mesh sieve. Add organic soil and commercial catalyst P25 with a mass ratio of 4:1 in a mortar, and mechanically grind for 15 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com