Heat-insulating external wallboard and manufacturing method thereof

A technology for thermal insulation exterior walls and thermal insulation layers, which is applied in the direction of walls, climate change adaptation, building components, etc., can solve the problems of thermal insulation layer setting method, improper material application measures, and failure to save energy resources for the society, so as to reduce the foundation and main body. The effect of engineering investment, saving raw materials and labor, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

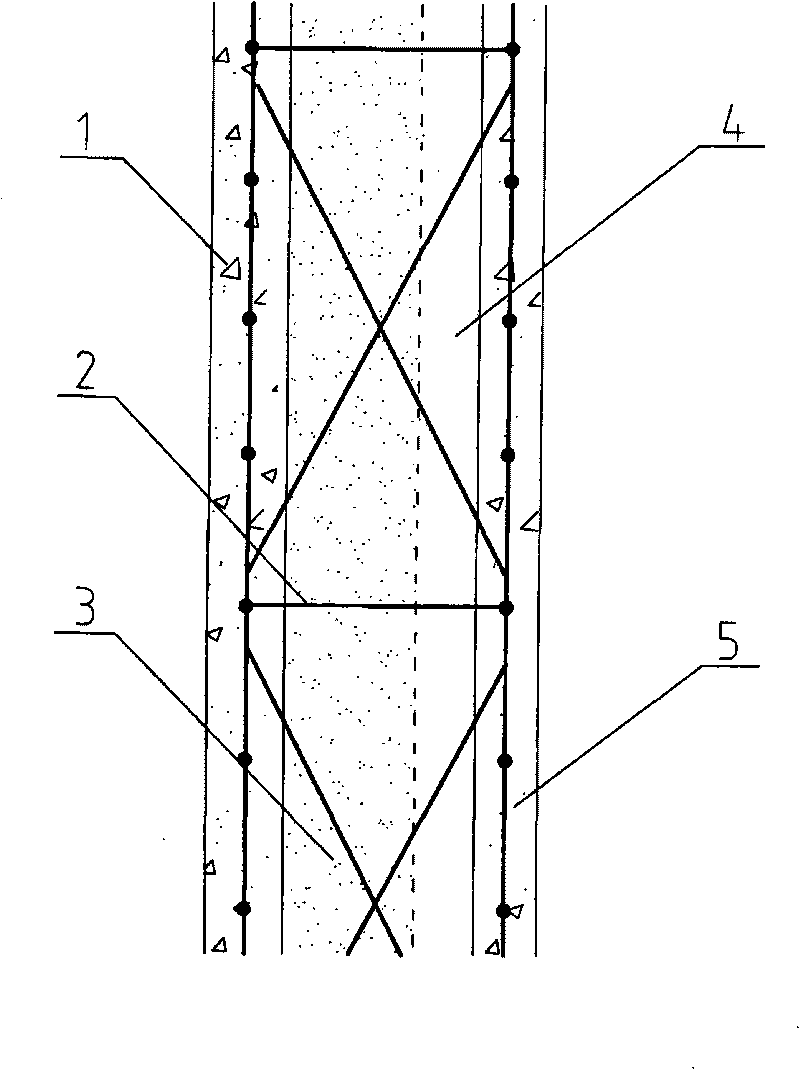

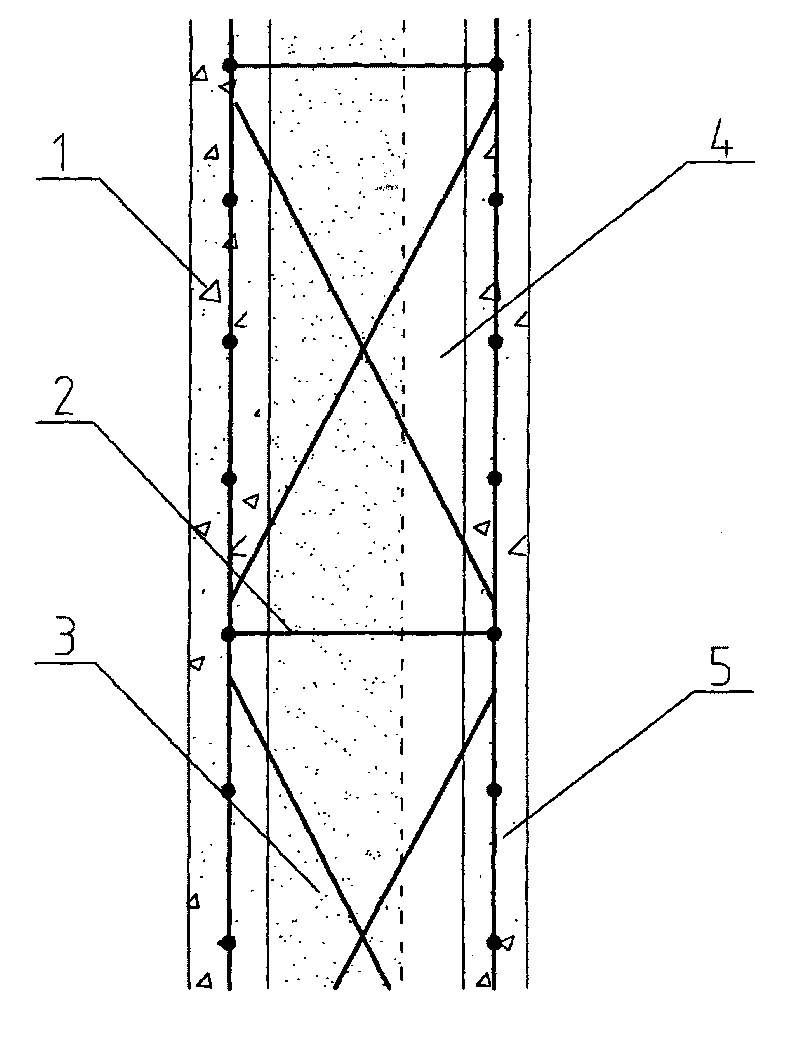

[0026] The steel wire grid skeleton 2 is made of galvanized steel wire, one side of which is fixedly connected to the outdoor concrete layer, and the other side is fixedly connected to the indoor concrete layer. Both the outdoor concrete layer 1 and the indoor concrete layer 5 are made of high-grade cement, It is made by mixing and stirring water, artificial hard rock sand, microsilica fume, first-class fly ash, alkali-resistant and anti-cracking fiber, and high-efficiency water reducer. The required mix ratio is C35-C40, and it is fixed on the inside of the concrete layer 1 outside the outdoor surface. Connect the insulation layer 3, the insulation layer 3 adopts one of foamed cement, expanded perlite, rock wool powder, polystyrene particle rubber powder, and rigid polyurethane foam, and has an air space layer 4 between it and the concrete layer 5 on the interior surface.

[0027] when making,

[0028] 1) Forming the skeleton of the steel wire mesh frame: use a CNC welding ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com