Electrical insulator fault detector and detecting method thereof

An insulator and detector technology, applied in the direction of testing dielectric strength, can solve problems such as high risk, difficult on-site measurement, and easy misjudgment, saving manpower and material resources, not being restricted by the environment, and improving work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

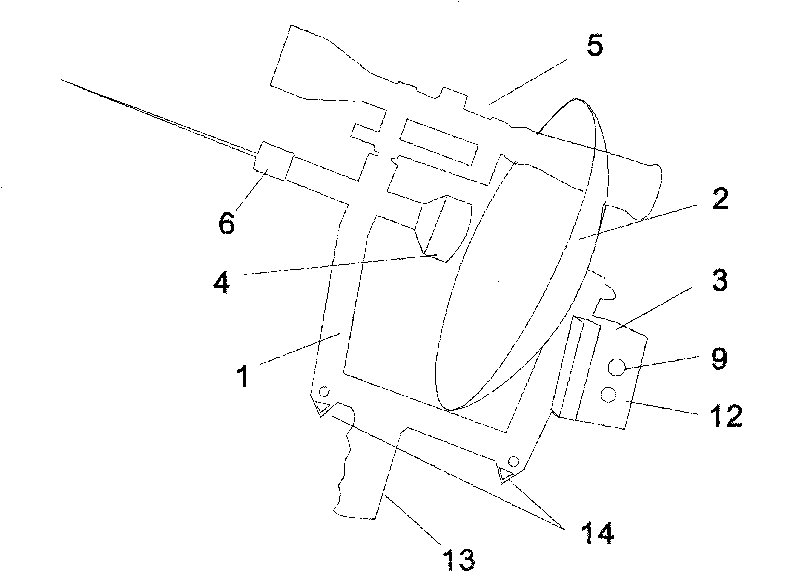

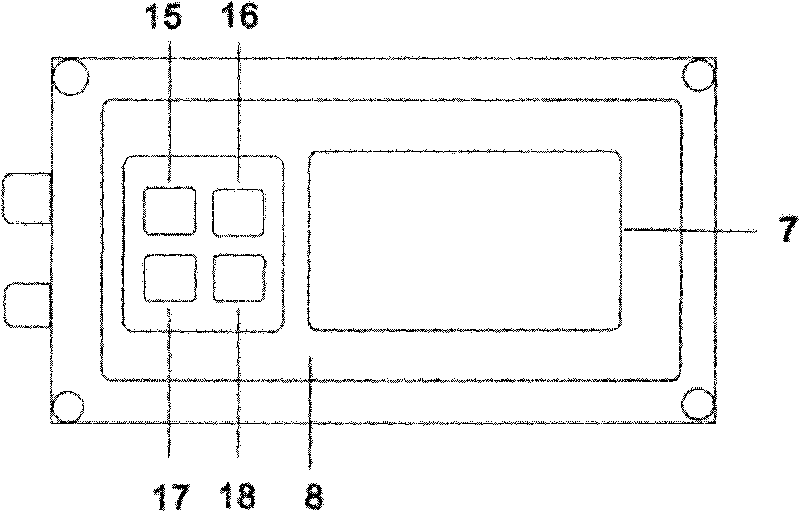

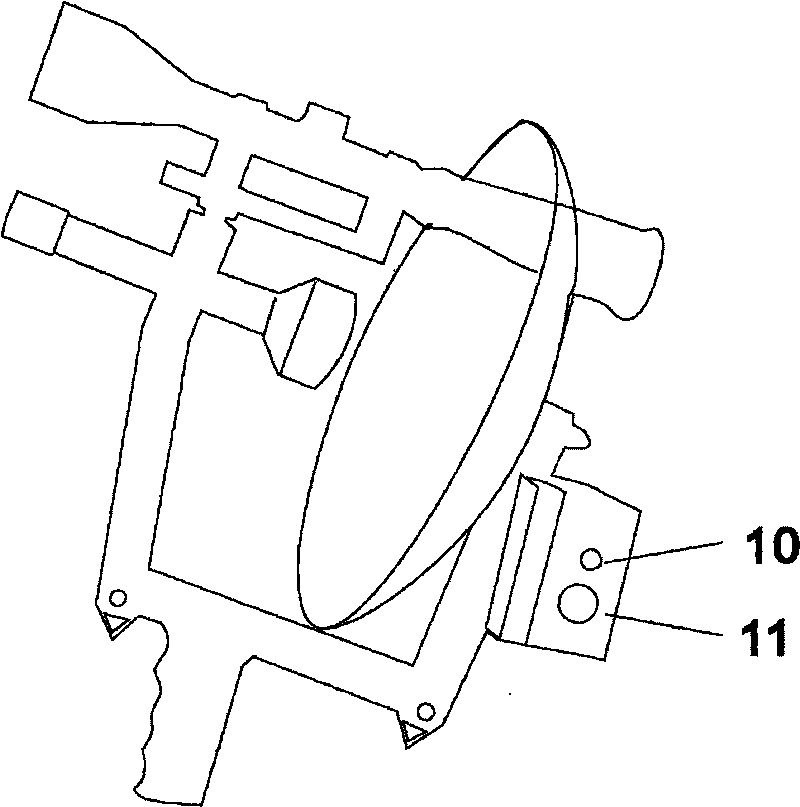

[0042] When the distance is 0 meters to detect the fault insulator of 10KV:

[0043] 1. Insert the earphone into the earphone jack 10, and adjust the sensitivity knob 9 to the maximum. 2. After completing the above step 1, press the power button 15 on the panel 8, adjust the contrast knob 12 to the point where the characters displayed on the LCD screen can be clearly seen, and the hand-held handle 13 is aligned with the insulator to be detected for detection. The detection distance The discharge sound of "click click" appears in the earphone, and the liquid crystal display shows that the intensity is 10, indicating that there is discharge in the insulator; 3. After completing the detection of the above step 2, press the laser 17 button on the panel 8, and the laser beam 6. Locate the discharge point and fault location of the faulty insulator by cooperating with the sight 5; 4. After completing the positioning of the above step 3, when it is detected that the discharge sound of...

Embodiment 2

[0045] When detecting a 35KV faulty insulator at a distance of 20 meters:

[0046] 1. Insert the earphone into the earphone jack 10, and adjust the sensitivity knob 9 to the maximum. 2. After completing the above step 1, press the power button 15 on the panel 8, adjust the contrast knob 12 to the point where the characters displayed on the LCD screen can be clearly seen, and the hand-held handle 13 is aligned with the insulator to be detected for detection. The detection distance The distance is 20 meters; the discharge sound of "click click" appears in the earphone, and the liquid crystal display shows that the intensity is 11, indicating that the insulator has discharge; 3. After completing the detection of the above step 2, press the laser 17 button on the panel 8, and the laser beam 6. Locate the discharge point and fault location of the faulty insulator by cooperating with the sight 5; 4. After completing the positioning of the above step 3, when it is detected that the d...

Embodiment 3

[0048] When detecting 110KV faulty insulators at a distance of 35 meters:

[0049] 1. Insert the earphone into the earphone jack 10, and adjust the sensitivity knob 9 to the maximum.

[0050] 2. After completing the above step 1, press the power button 15 on the panel 8, adjust the contrast knob 12 to the point where the characters displayed on the LCD screen can be clearly seen, and the hand-held handle 13 is aligned with the insulator to be detected for detection. The detection distance The distance is 35 meters; there is a "click click" discharge sound in the earphone, and the LCD display shows an intensity of 12, indicating that the insulator has a discharge;

[0051] 3. After completing the detection of the above step 2, press the laser 17 button on the panel 8, and the laser beam 6 passes through the collimating mirror 5 to locate the discharge point and fault location of the faulty insulator;

[0052] 4. After completing the positioning of the above step 3, when it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com