Novel flat-sheet membrane module

A flat membrane and component technology, applied in the field of membrane separation, can solve the problems of uneven pressure distribution, single online cleaning method, large filtration resistance, etc., achieve uniform pressure distribution in the cavity, delay the chemical cleaning cycle, and effectively filter the area. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

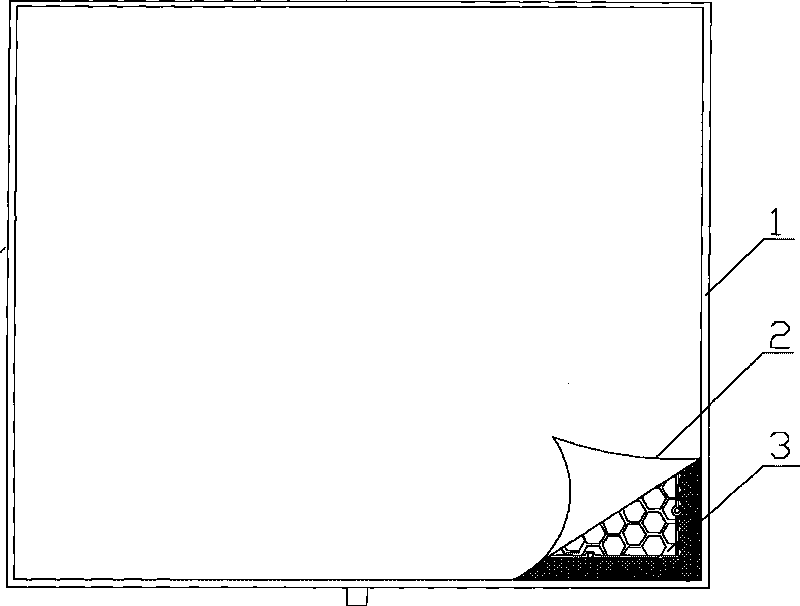

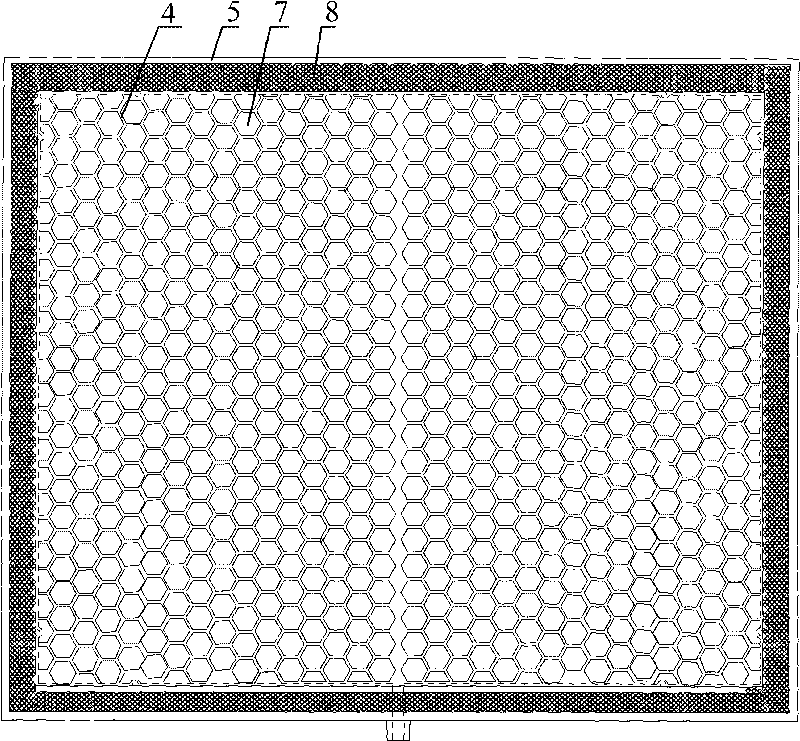

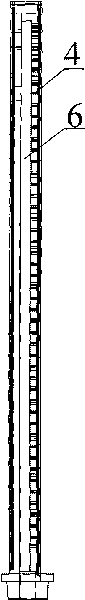

[0022] Such as figure 1 As shown, the new flat membrane component 1 includes a filter membrane 2 and a supporting membrane 3 for fixing the filter membrane. The supporting diaphragm 3 is a three-dimensional structure, such as Figure 2a , 2b As shown, the supporting membrane 3 is composed of a front and rear mesh plate 4 and a frame 5. Two front and rear mesh plates 4 are clamped in parallel to form a hollow cavity 6, and the mesh plates 4 on the front and rear sides are evenly arranged The densely clothed filter mesh 7 is provided with filter membrane sticking tapes 8 on both sides of the frame 5 to stick the filter membrane on the front and back sides of the membrane plate, so that the membrane element has a double-sided filtering function and improves the packing density of the filter membrane. Such as Figure 3a , 3b In the hollow inner cavity, a number of reinforcing ribs 9 are provided on one side of the mesh plate. The reinforcing ribs 9 are used to improve the strength o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com