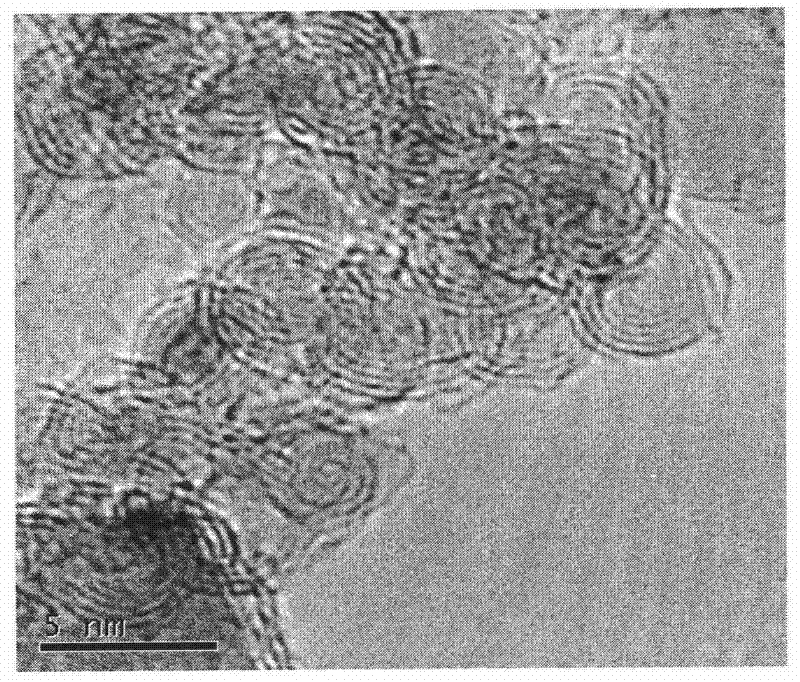

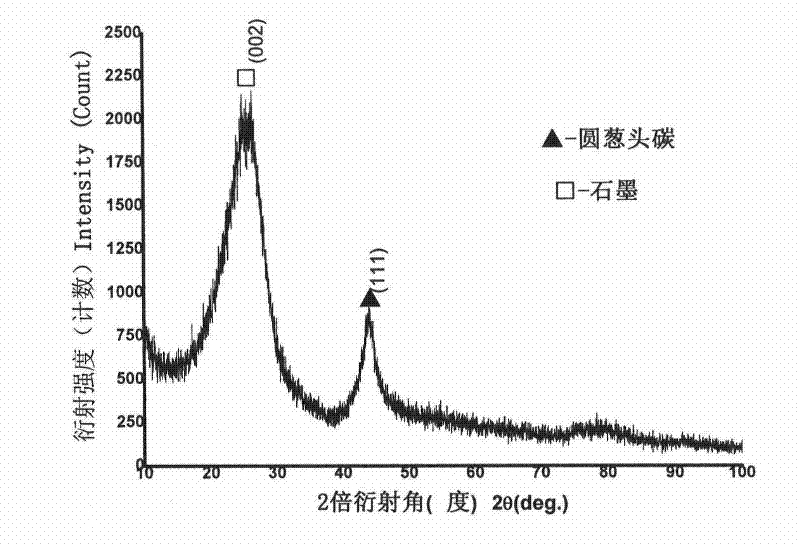

Method for preparing polycrystalline diamond sintered body by nano onion head-carbon high temperature and high pressure

A high-temperature, high-pressure, onion-head technology, which is applied in the field of manufacturing superhard polycrystalline diamond sintered bodies, can solve problems such as difficult industrialized production, and achieve the effects of smooth surface, reduced brittleness, and fine grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

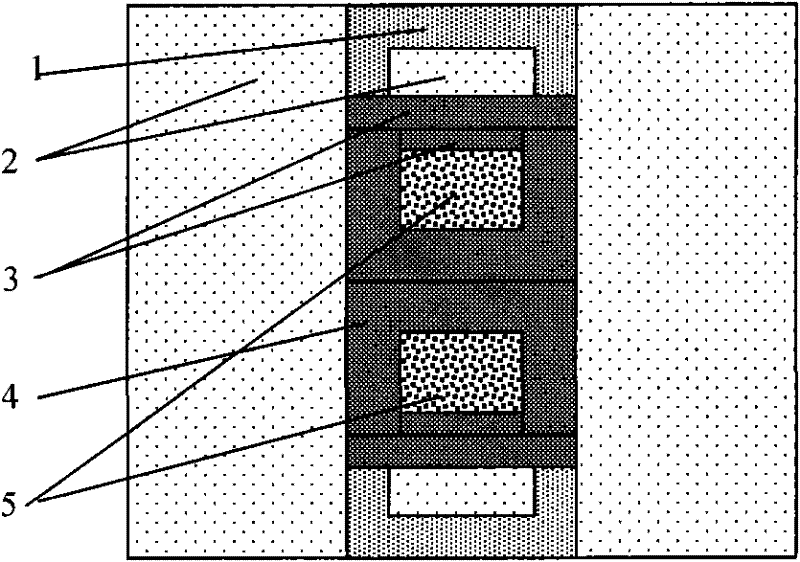

[0018] Accurately weigh the nano-onion-carbon 5, put it into a prefabricated mold, and prefabricate the sample at 60 MPa on an ordinary hydraulic press at room temperature; put the sample into the graphite tank 4 after demoulding, and mix with the pressure transmission medium pyrophyllite 2, graphite Sheet 3, conductive steel cap 1 form assembly block (see image 3 ), kept in a drying oven at 160°C for 6 hours. Take it out from the drying box and place it in the working part of the CS-1B six-sided press, which is produced by Guilin Metallurgical Machinery Factory; nominal pressure: (single cylinder) 8000KN.

[0019] After the six-sided top press is started, first raise the pressure to 4.5GPa, heat while maintaining the pressure, keep it at 500-550°C for 60s, then raise the temperature to 1200-1250°C, keep it at this temperature for 180s, and then stop heating , when the temperature drops below 100°C, the pressure is slowly released, the composite block is taken out, the press...

Embodiment 2

[0021] After the same pre-processing method as in Example 1, the assembled block is placed on the working surface of the six-sided top press, the press is started, the pressure is raised to 5.2-5.5GPa, maintained under this pressure, and the temperature is raised to 500- 550°C, hold for 60s, then rise to 1500-1550°C, hold for 120s; remove the pressure, cool down, take out the assembly block and post-treatment are the same as in Example 1 to obtain a φ6×5mm polycrystalline diamond sintered body, the average Vickers hardness test The hardness is 60.8GPa, and the grain size is 14.4nm;

[0022] The present invention uses nano-onion-carbon as the only raw material, and adds any other additives such as binders or reaction sintering catalyst materials, and its sintering temperature and pressure are significantly lower than those of similar products that use diamond particles as raw materials without additives (Kenichi K, Staom K, ctal. J. Am. Ccram. Soc, 1996(1). P97). The polycryst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com