Method for preparing activated carbon activated by combining flue gas and water vapor in stokehole

A composite activation, activated carbon furnace technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of dispersion, large amount and high cost, and achieve the effect of reducing production cost, high activity and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

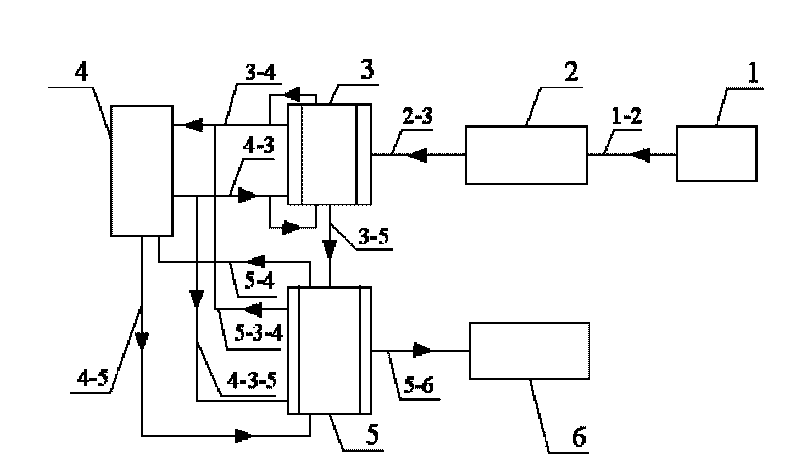

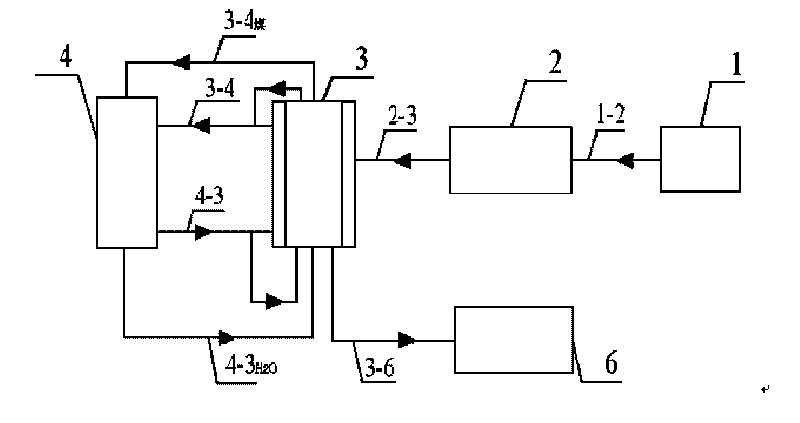

[0015] Specific implementation mode one: combine figure 1 In this embodiment, the activated carbon furnace preparation method of flue gas and water vapor combined activation is realized according to the following steps: 1. The raw coal is sent from the raw coal storage bin 1 to the raw coal crushing and screening chamber 2 via the conveyor belt 1-2, and after screening The raw coal particles with a particle size of 3-5 mm enter the carbonization furnace 3 for carbonization through the raw coal particle conveying belt 2-3, and the high-temperature hot flue gas drawn from the boiler 4 supplies heat for the carbonization furnace 3, and the heating flue gas circuit of the carbonization furnace 3 It consists of a boiler 4, a carbonization furnace hot flue gas pipeline 4-3, an outer heating layer of the carbonization furnace 3, and a boiler hot flue gas pipeline 3-4, and a bypass is provided on the carbonization furnace hot flue gas pipeline 4-3 A stream of hot flue gas is used as a...

specific Embodiment approach 2

[0016] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the amount of hot flue gas purged per 1 kg of raw coal particles in step 1 is 0.03 Nm 3 / h~0.05Nm 3 / h. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0017] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the activation loss on ignition of the water vapor described in step 2 is 45% to 50%. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com