Method for producing building lightweight wall board by using tailings powder as raw material

A technology for tailings powder and raw materials, applied in the field of building materials, can solve the problems of not conforming to the national development strategy, destroying resources to produce building materials, etc., achieving the effects of light weight, good fire resistance and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

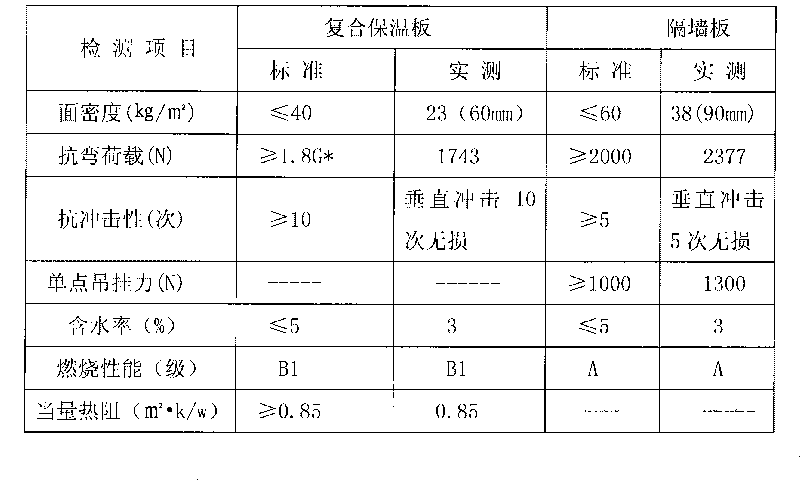

Image

Examples

Embodiment 1

[0029] (1), magnesium chloride is dissolved into the solution that wave ratio concentration is 25, and in dissolving process, solution produces a large amount of heat energy, heat energy is extracted with the plate heat exchanger installed in the magnesium chloride dissolving tank (or tank), as production The required heat energy is used, which saves energy and ensures that the temperature of the magnesium chloride solution is between 25°C and 30°C;

[0030] (2), the content is 80% magnesia and the tailings powder that fineness is more than 200 orders is mixed by the ratio of 6.5: 4 and puts into the mixer for use; concrete adding weight is: 100kg80% magnesia and 61.5kg tailings powder

[0031] (3), according to the weight of 80% magnesium oxide in the step (2), by magnesium oxide and magnesium chloride solution mol ratio is the ratio calculation of 6.5: 1, adding wave ratio concentration is 25 magnesium chloride solution 90kg, adds in the magnesite mixer, And by the weight r...

Embodiment 2

[0052] (1), dissolving magnesium chloride into a solution with a wave ratio concentration of 30, in the dissolution process, the solution produces a large amount of heat energy, which is extracted with a heat exchanger and used as the heat energy required for production, saving energy. And ensure that the temperature of the magnesium chloride solution is between 25°C and 30°C;

[0053] (2), the content is 85% magnesia and the tailings powder that fineness is more than 200 meshes are mixed by the ratio of 8:5 and put into the mixer for use, wherein 85% magnesia is 100kg, tailings The weight of powder is 62.5kg;

[0054] (3), according to the weight of 80% magnesium oxide in the step (2), by the ratio of magnesium oxide and magnesium chloride mol ratio 7.5: 1, the wave ratio concentration is that 25 magnesium chloride solution 110kg is added in the magnesite mixer; Press magnesium chloride solution and Add 1.1kg of environmental additives in a weight ratio of 100:1, and prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com