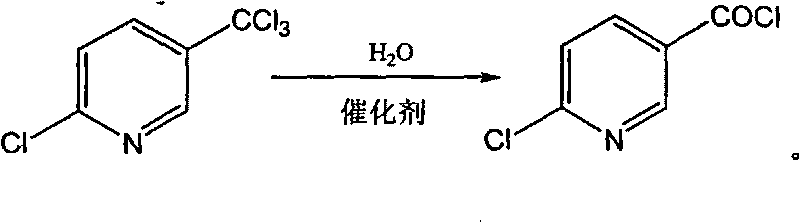

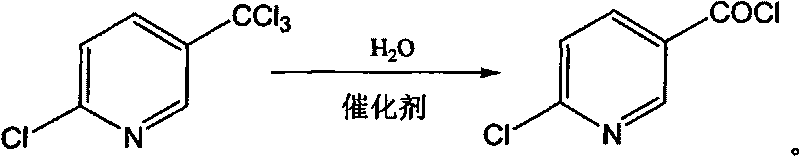

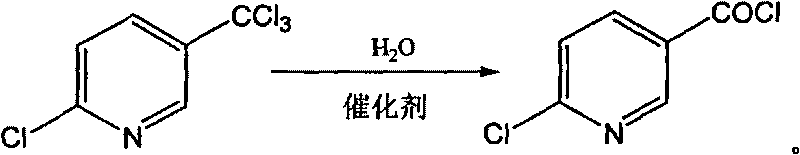

Method for synthesizing 6-chloropyridine-3-carbonyl chloride

A technology of carbonyl chloride and chloropyridine, which is applied in the field of synthesis of 6-chloropyridine-3-carbonyl chloride, can solve the problem of high price of 6-chloropyridine-3-carbonyl chloride, and achieve easy control of industrial production, mild reaction conditions, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Add 231g of 2-chloro-5-trichloromethylpyridine in a 500ml four-necked reaction flask equipped with an agitator and a thermometer tail gas absorption device, add 11.55g (5%) of ferric chloride, slowly heat up to 95°C, and slowly drop Add 18g of distilled water, after completion of the dropwise addition, heat-preserved and stirred for 8 hours, after the reaction, the reaction solution was directly distilled under reduced pressure, collected at 83-85°C / 3mmHg, and 170.2g of a solid with a white melting point of 50°C was obtained, of which 6 -Chloropyridine-3-carbonyl chloride has a purity of 97.4% and an actual yield of 94.1%.

Embodiment 2~4

[0021] Reaction technology is identical with example 1, and the molar ratio of water and 2-chloro-5-trichloromethylpyridine is 1: 1, and concrete process parameter and result are shown in Table 1:

[0022] Process parameter and result of table 1 embodiment 2~4

[0023]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com