Method for improving strength and plasticity of whisker reinforced pure aluminium-based composite material

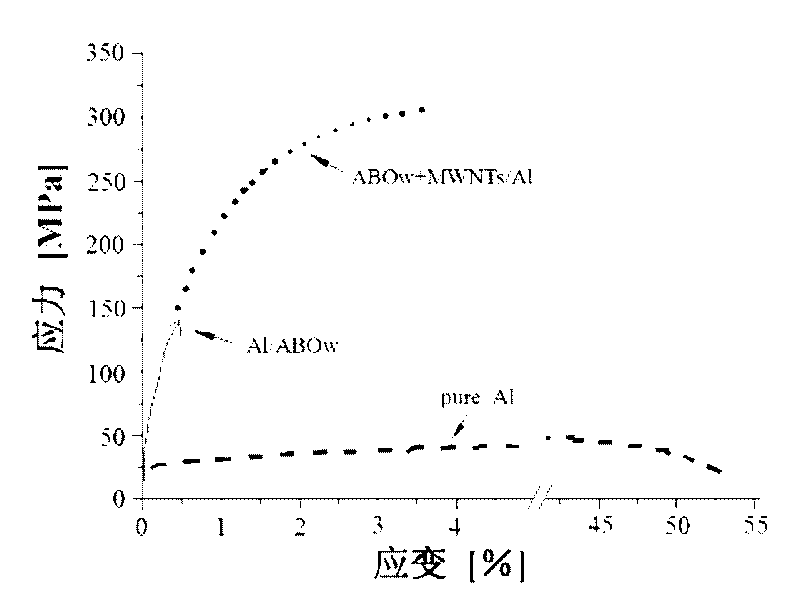

A composite material and whisker technology, which is applied in the field of improving the strength and plasticity of pure aluminum-based composite materials, can solve the problems of low elongation of pure aluminum-based composite materials, and achieve the effects of increased elongation, yield strength and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

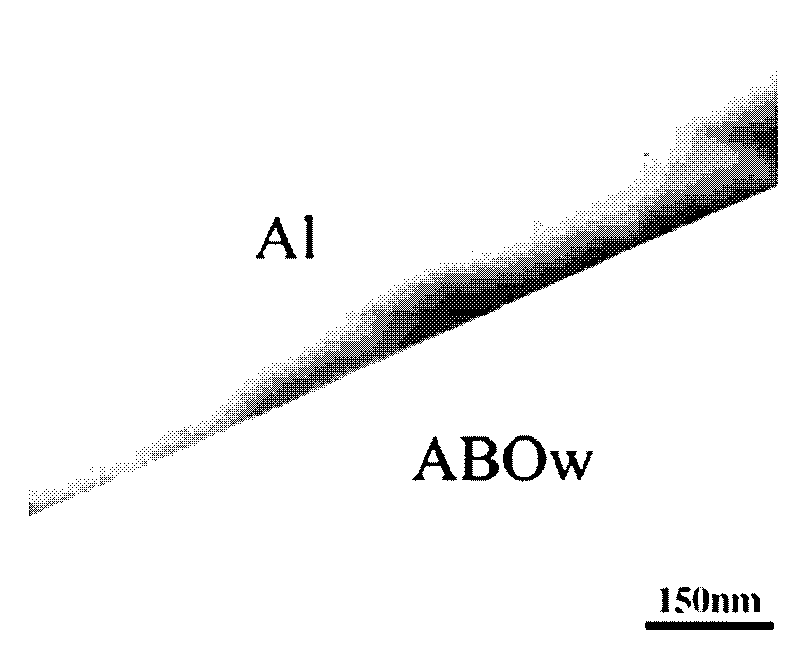

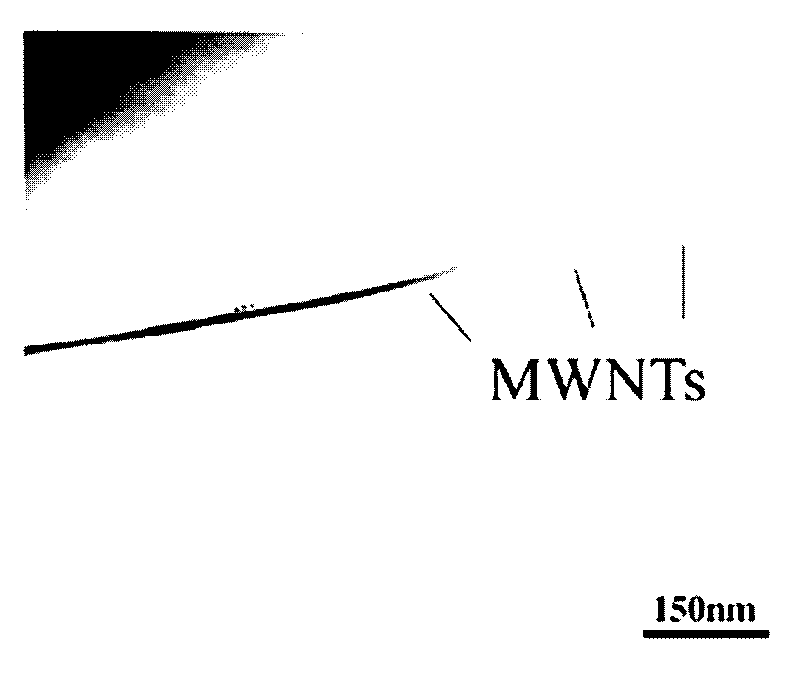

[0009] Specific Embodiment 1: The method for improving the strength and plasticity of whisker-reinforced pure aluminum matrix composites in this embodiment is carried out through the following steps: 1. According to the volume fraction of whiskers and carbon nanotubes in the prefabricated block and the height of the prefabricated block , according to m=0.25×10 -2 ×π×D 2 ×H×V f ×ρWeigh aluminum borate whiskers with a diameter of 0.1-1μm and carbon nanotubes with a diameter of 10-30nm, where m is the mass of the whiskers or carbon nanotubes to be weighed, and the unit of m is g, D Is the diameter of the prefabricated block, the unit of D: cm, H is the height of the prefabricated block, the unit of H: cm, V f is the volume percentage of whiskers or carbon nanotubes in the prefabricated block, ρ is the density of whiskers or carbon nanotubes, and the unit of ρ is g / cm 3 , the whiskers are silicon carbide whiskers or aluminum borate whiskers; 2. Purify the carbon nanotubes weigh...

specific Embodiment approach 2

[0010] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the volume fraction of carbon nanotubes in the prefabricated block described in step 1 is 0.2-0.6%, and the volume fraction of whiskers in the prefabricated block is 18-25%. %. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the volume fraction of the carbon nanotubes described in step one in the prefabricated block is 0.3-0.%, and the volume fraction of the whiskers in the prefabricated block is 20-0.0%. twenty three%. Other steps and parameters are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com