Method for manufacturing cotton white paper

A manufacturing method and technology of white paper, applied in the field of paper manufacturing, can solve the problems of weak specificity, poor matching of equipment, lack of high-grade papermaking chemicals, etc., to improve softness and water absorption, reduce production costs, and smooth appearance delicate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

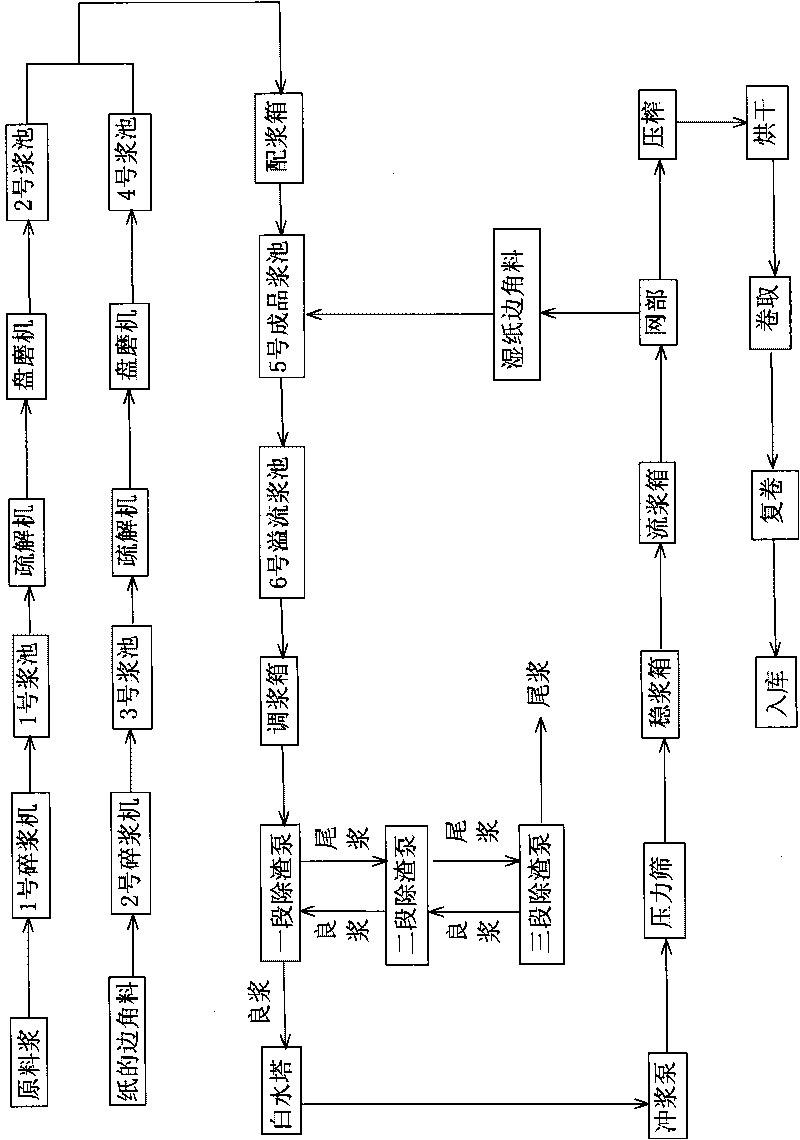

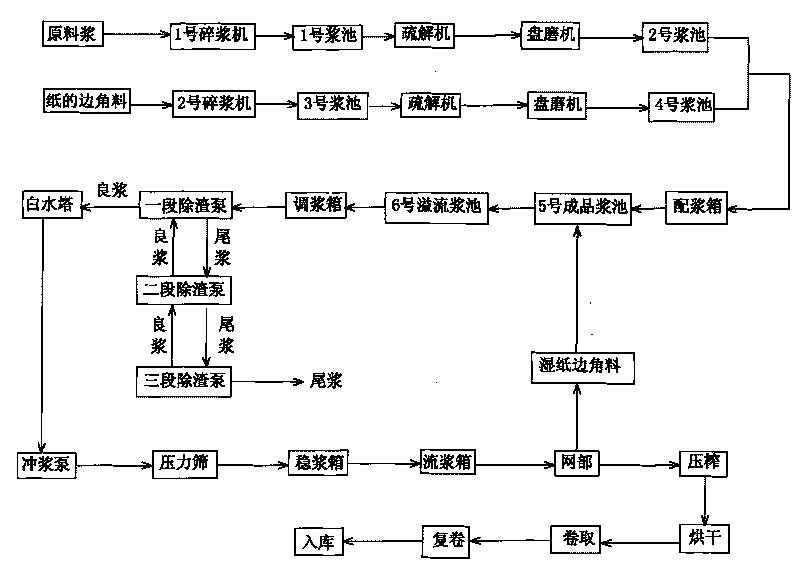

Image

Examples

Embodiment 1

[0025] Embodiment 1: As shown in the accompanying drawing, the mass concentration of 100% bleached sulfite eucalyptus pulp is adjusted with water to form a mass concentration of 3% slurry, and then the slurry is pulped by No. 1 hydraulic pulper and entered into No. 1 pulp pool , and then the slurry in the No. 1 pulp pool is decomposed by the deflagging machine, and the coarse fiber is ground by the disc refiner, and then enters the No. 2 pulp pool; then the slurry in the No. Put in PPE papermaking wet strength agent and mix to obtain finished slurry, wherein the amount of PPE papermaking wet strength agent added is 18 kg per ton of paper; the finished slurry is transported to No. 5 finished pulp tank, and pumped into the No. 5 finished pulp tank The pulp is sent to the No. 6 overflow pulp tank and the overflow pulp tank is always full. The overflow pulp tank flows into the No. 5 finished pulp tank through the overflow pipe, and the No. 6 overflow pulp tank The mass concentrati...

Embodiment 2

[0026] Embodiment 2: 100% mass concentration 100% bleached sulfite eucalyptus pulp is added with water and adjusted to a mass concentration of 4% slurry, and then the slurry enters No. 1 pulp tank through pulper pulping, and the slurry in No. 1 pulp storage tank After being decomposed by a deflaker and coarsely ground by a disc refiner, it enters the No. 2 pulp tank; then the slurry in the No. 2 pulp tank is transported to the pulp mixing box, and at the same time, PPE papermaking wet strength agent is put into the pulp mixing box and mixed to obtain finished pulp The amount of PPE papermaking wet strength agent added is 20 kg per ton of paper; the finished slurry is transported to the No. 5 finished stock tank, and the pump is used to send the slurry in the No. 5 finished stock tank to the No. 6 overflow pulp and make the overflow stock tank always full. The overflow stock from the overflow stock tank flows into No. 5 finished stock stock through the overflow pipe. Adjusted t...

Embodiment 3

[0027] Embodiment 3: It is basically the same as Embodiment 1, except that the bleached sulfite eucalyptus pulp with a mass concentration of 100% is adjusted to a slurry with a mass concentration of 3.5% by adding water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com