Method and device for installing and regulating light equipment and steel structure

A technology for installation and adjustment, steel structure, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of complex process and cumbersome operation, achieve the effect of high social value, reduce consumption, and simplify the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

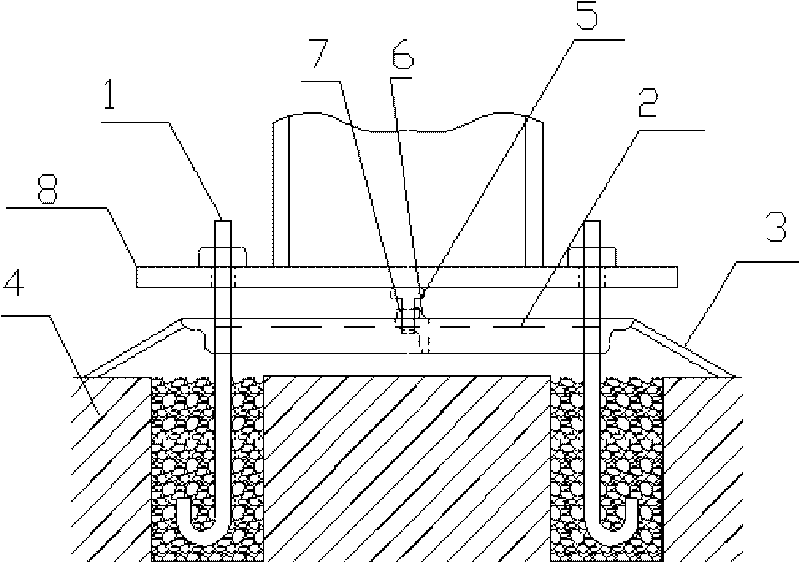

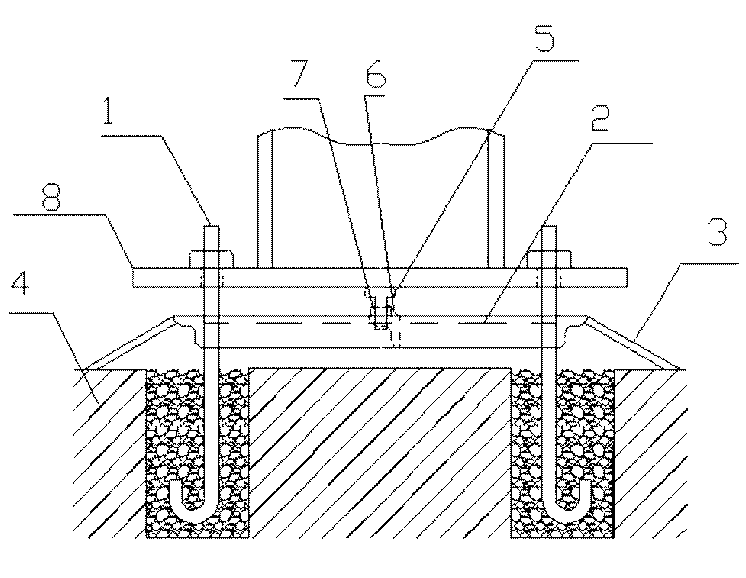

[0022] (1) First, carry out setting-out measurement and inspection on the reserved holes of the foundation and anchor bolts, and the allowable deviation of the verticality of the center line of each of the reserved holes of the anchor bolts is 1mm; (2) use four angle steels 2 to The lower parts of the four anchor bolts 1 are connected in pairs to form a frame structure; (3) Put the fixed four anchor bolts into the reserved holes and adjust according to the required accuracy. The outer side of the angle steel is fixed by welding the reinforced plate 3 and the embedded parts on the foundation 4. The installation allowable deviation of the height of the top surface of each of the anchor bolts 1 is -1mm, and the center of the adjacent anchor bolts The position deviation of the connecting line is 0.5mm; (4) After each of the anchor bolts is adjusted, the anchor bolt holes are grouted. After the anchor bolt holes are grouted, the verticality deviation of the axis of the anchor bolts ...

Embodiment 2

[0025] (1) First, carry out setting-out measurement and inspection on the reserved holes of the foundation and anchor bolts, and the allowable deviation of the verticality of the center line of each of the reserved holes of the anchor bolts is 0.5mm; (2) Use four angle steels 2 Connect the lower parts of the four anchor bolts 1 in pairs to form a square frame structure; (3) put the fixed four anchor bolts into the reserved holes and adjust according to the required accuracy. The outer side of an angle steel is fixed by welding the reinforced plate 3 and the embedded parts on the foundation 4. The installation allowable deviation of the height of the top surface of each of the anchor bolts 1 is -0.5mm, and the adjacent anchor bolts The positional deviation of the center connection line is 1mm; (4) After each of the anchor bolts is adjusted, the anchor bolt holes are grouted. After the anchor bolt holes are grouted, the verticality of the axis of the anchor bolts The deviation i...

Embodiment 3

[0028] (1) Firstly, carry out setting-out measurement and inspection on the reserved holes of the foundation and anchor bolts, and the allowable deviation of the verticality of the center line of each of the reserved holes of the anchor bolts is -0.5mm; (2) use four angle steels 2. Connect the lower parts of the four anchor bolts 1 in pairs to form a square frame structure; (3) Put the fixed four anchor bolts into the reserved holes and adjust according to the required accuracy. The outer side of each angle steel is fixed by welding the reinforcement plate 3 and the embedded parts on the foundation 4, the installation allowable deviation of the height of the top surface of each of the anchor bolts 1 is 1 mm, and the adjacent anchor bolts The position deviation of the center line is -1mm; (4) After each of the anchor bolts is adjusted, grout the anchor bolt holes. After the anchor bolt holes are grouted, the verticality of the axis of the anchor bolts The deviation is -1mm; (5)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com