Jet engine of seaplane

A seaplane and engine technology, applied in the direction of ramjet engine, mechanical equipment, etc., to achieve the effect of high power and explosive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

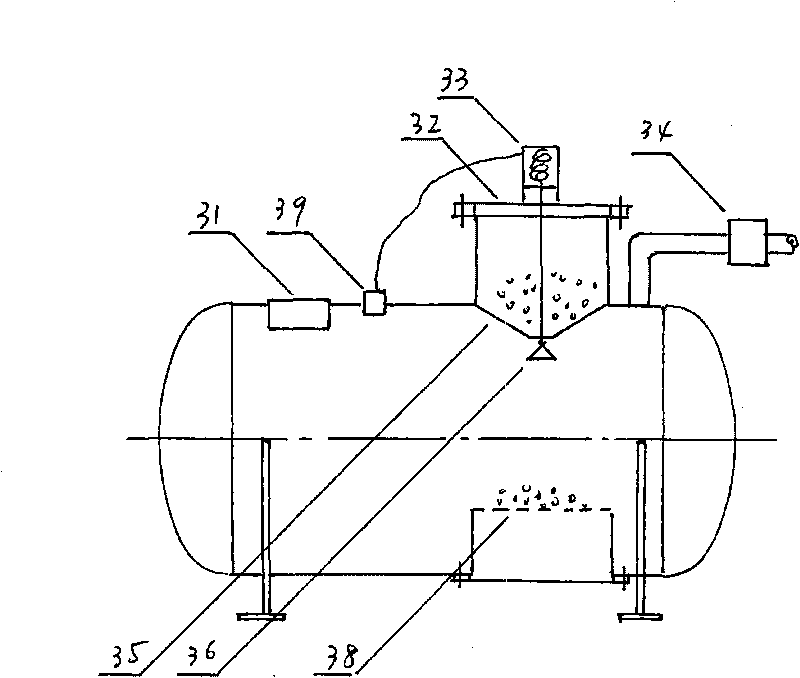

[0059] figure 1 It is the structural diagram of the acetylene generator of the jet engine embodiment of the seaplane of the present invention.

[0060] The basic structure of the acetylene generator of the injection engine embodiment is a pressure vessel placed horizontally, with left and right seal heads plus a cylinder in the middle. The top of the cylinder is provided with a calcium carbide bin 32. The calcium carbide bin 32 is cylindrical and has a calcium carbide funnel 35 at the bottom. There is a liftable valve 36 under the discharge port of the calcium carbide funnel 35. The height of the valve 36 affects the discharge of the calcium carbide funnel 35. The actual outlet area of the feed port also affects the amount of calcium carbide. On the upper cover of the calcium carbide bin 32, there is a pressure regulator 33 whose input sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com