Novel process for coupling utilization of waste heat recovery of riser of coke oven and coke dry quenching system

A technology of waste heat recovery and coke CDQ, which is applied in the steam generation method using heat carrier, coke oven, coke cooling, etc., can solve the problems of energy waste, imperfect thermodynamics, etc., and achieve good safety and reliability and great economic benefits And environmental benefits, good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

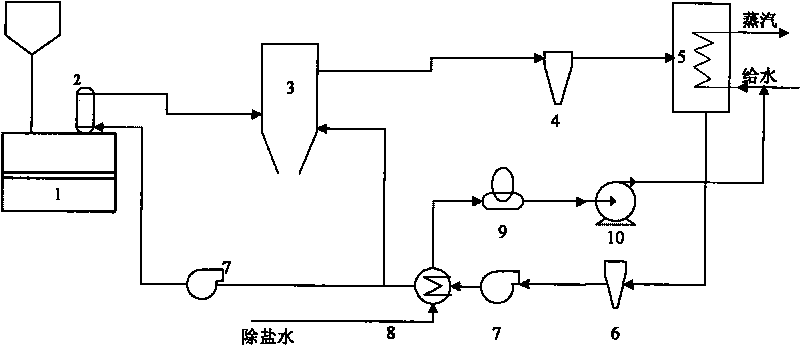

[0025] The process of the present invention is formed by coupling the coke dry quenching system and the waste heat utilization of the riser pipe, and the coke dry quenching circulating gas plays a connecting role.

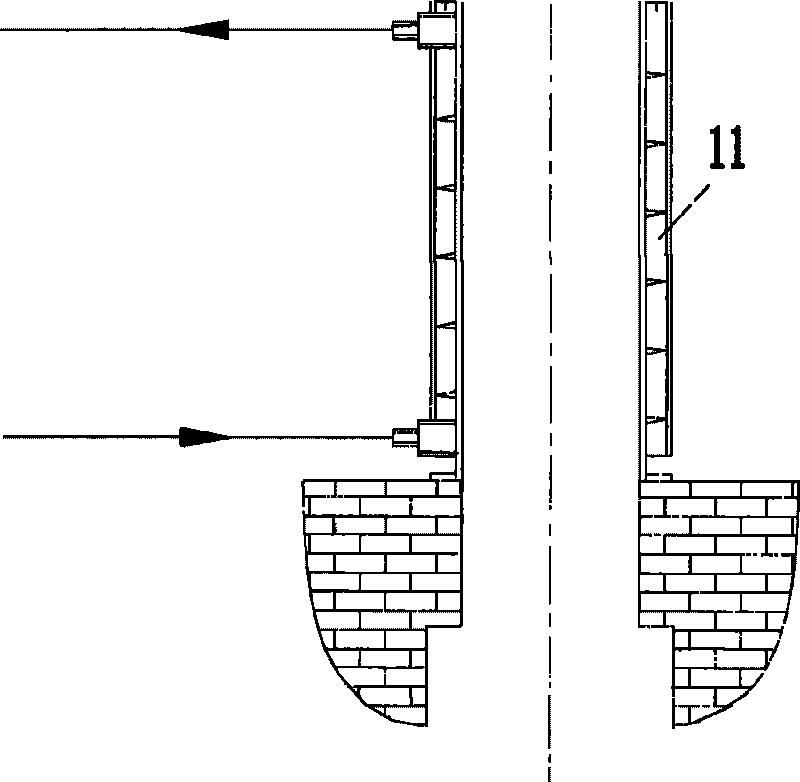

[0026] The invention is attached figure 1As shown, the rising pipe waste heat utilization system is coupled with the CDQ furnace of the CDQ system, including coke oven 1, rising pipe heat exchange device 2, CDQ furnace 3, primary dust collector 4, waste heat boiler 5, secondary dust removal Device 6, heat pipe heat exchanger 8, boiler feed water pump 10, deaerator 9 and circulation fan 7. The specific process flow is as follows: At the outlet of the heat pipe heat exchanger 8 of the CDQ system, part of the CDQ circulating gas at about 130°C is drawn out, and the CDQ gas here passes through the waste heat boiler 5 and the heat pipe heat exchanger 8, and the temperature Down to the lowest point of the system, the circulating gas is sent to the waste heat recovery de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com