Airflow drying device for dispersed material

An airflow drying and material technology, applied in the direction of drying gas arrangement, drying machine combination, drying solid materials, etc., can solve the problems of complex structure of solid material circulation device, impingement flow is difficult to meet the drying requirements, and cycle drying time is difficult to control, etc., to achieve The effect of prolonging the intensive drying time, improving the utilization efficiency of heat medium, and uniform radial distribution of gas and solid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

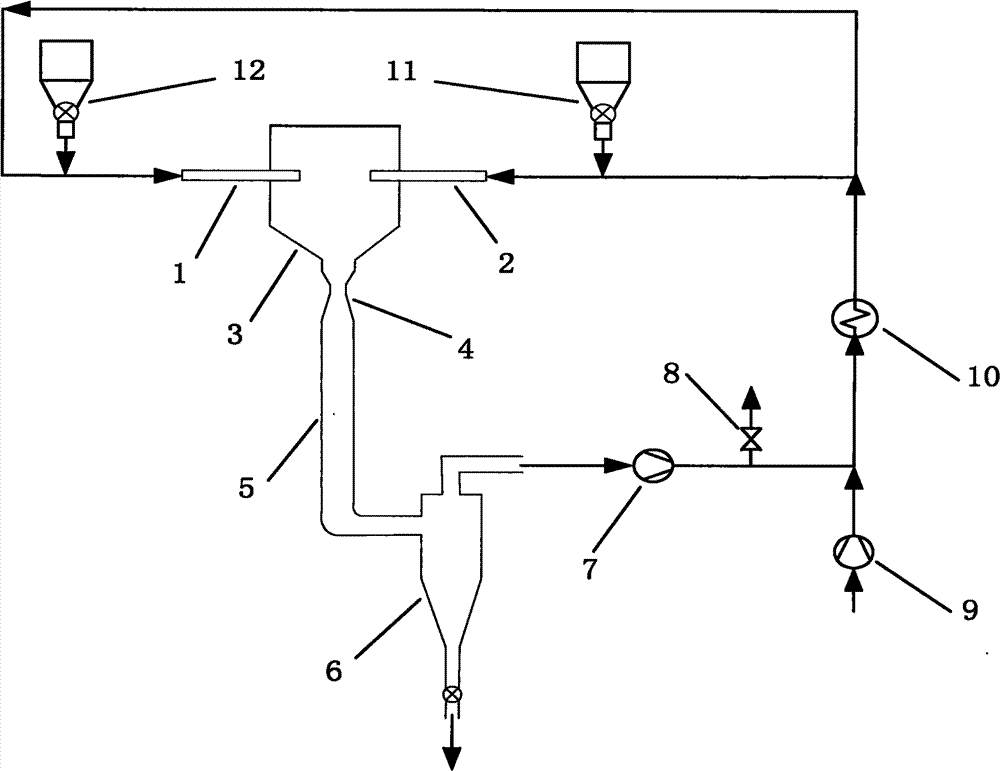

[0022] Taking the drying of shredded tobacco in tobacco processing as an example, as shown in Figure 1, the moisture content of the shredded tobacco sent into the bin 11 after the shredding process is between 18% and 22%. Enter the acceleration tube 2, the gas velocity in the acceleration tube is between 15-30m / s, and the temperature of the hot air is between 120-250°C. In order to reduce the crushing of tobacco materials, only one hot air carries the materials in the coaxial horizontal impinging flow contactor. The two fluids enter the coaxial horizontal impinging flow contactor barrel 3 through the accelerating tube, forming an impacting area in the contactor. After leaving the impacting area, the shredded tobacco falls into the lower part of the impinging flow contactor. Carried by the hot air, the shredded tobacco passes through the Venturi distribution. The device 4 enters the gas-solid and flows down the descending bed 5. After the cut tobacco is dried in the coaxial ho...

Embodiment 2

[0024] Taking the drying of grain feed pellets as an example, as shown in Figure 1, the hot air carries the materials into the acceleration tube 1 and the acceleration tube 2 respectively, and the two streams enter the coaxial horizontal impingement flow contactor cylinder 3 through the acceleration tube, forming a flow in the contactor. In the impact area, the grain feed particles leave the impact area and fall into the lower part of the impact flow contactor. Carried by the hot air, they enter the gas-solid co-current descending bed 5 through the Venturi distributor 4 . After the grain feed particles are dried in the coaxial horizontal impingement flow contactor and the gas-solid co-current down-flow bed, they are separated by the cyclone separator 6 and discharged through the discharge valve, and the hot air is recycled after dehumidification.

Embodiment 3

[0026] Taking the drying of PVC powder particles as an example, as shown in Figure 1, the hot air carries PVC powder particles into the acceleration tube 1 and the acceleration tube 2 respectively, and the two fluids enter the coaxial horizontal impingement flow contactor cylinder 3 through the acceleration tube. An impact area is formed, and PVC powder particles leave the impact area and fall into the lower part of the impact flow contactor, carried by the hot air, and enter the gas-solid co-flow down-flow bed 5 through the Venturi distributor 4 . After the PVC powder particles are dried in the coaxial horizontal impingement flow contactor and the gas-solid co-current down-flow bed, they are separated by the cyclone separator 6 and discharged through the discharge valve, and the hot air is recycled after dehumidification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com