Light filter with two conductive metal foils and plasma display using same

A plasma display and conductive metal technology, applied in the field of optical filters, can solve problems such as erosion, non-sticking, and reduced electromagnetic radiation shielding ability, and achieve the effect of improving oxygen barrier and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

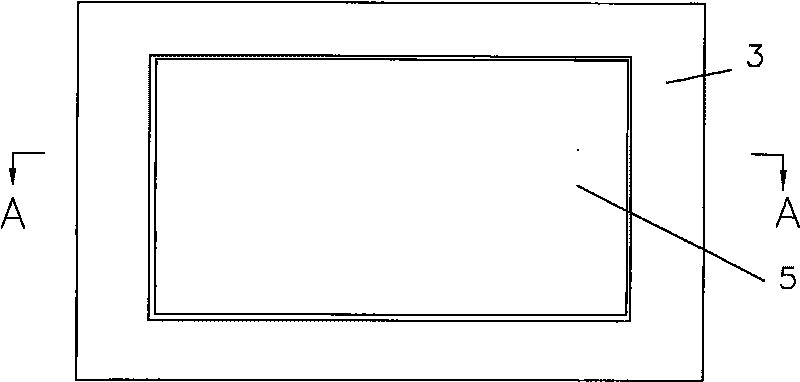

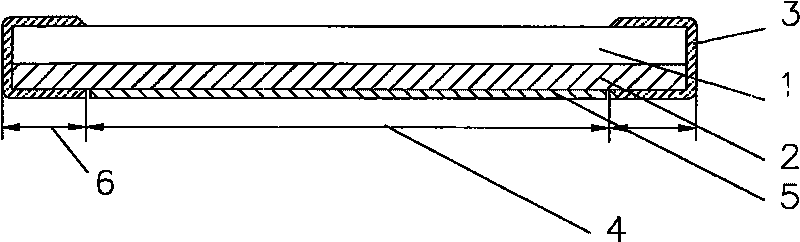

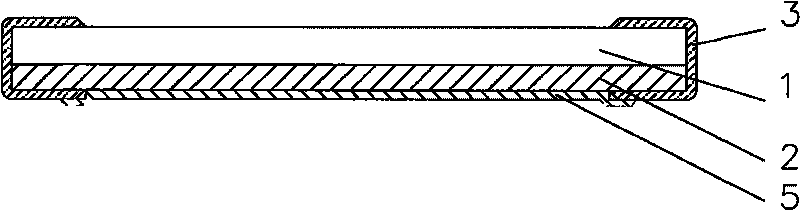

[0021] Figure 4 The structure diagram of the optical filter with two layers of conductive metal foil in the present embodiment 1 is given, see Figure 4 One side of the transparent substrate 1 (can be glass) is coated with a coating layer 2 for electromagnetic shielding (or is pasted with a copper mesh layer containing an adhesive layer pasted with the substrate for electromagnetic shielding), and the first layer of conductive metal foil 3 (Containing the conductive adhesive layer) A part of the conductive adhesive of the metal foil is used to paste the coating layer 2 (or copper mesh layer) along the edge of the substrate, and the other part is coated along the edge of the substrate to The other side of the substrate is also pasted with the substrate to form a coating on the edge of the substrate 1 and the coating layer 2, and on the coating layer 2 (or the copper mesh layer) is compounded with a layer of protective coating layer (or copper mesh layer). The resin layer 5 th...

Embodiment 2

[0023] Figure 5 Provided the figure of present embodiment 2, the optical filter sheet 8 that has two layers of conductive metal foils in the present embodiment is pasted together directly with the screen of display 9 with bonding agent 10, and this embodiment has thinned plasma display, Secondary reflections of the image are completely prevented.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com