Preparation method of crystal silicon solar cell

A technology of solar cells and crystalline silicon, applied in the field of solar photovoltaic utilization, can solve the problems of expensive, unsuitable for large-scale, and low-cost industrial production, and achieve the effects of easy operation, good application prospects, and improved conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

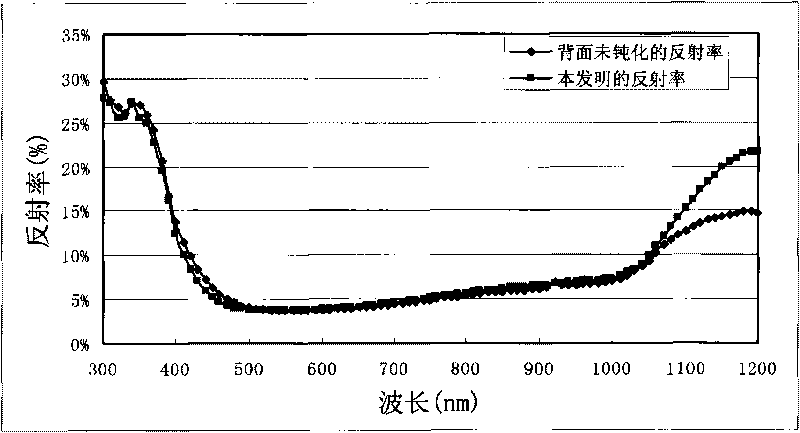

[0023] See attached figure 1 Shown, a kind of preparation method of crystalline silicon solar cell comprises the steps:

[0024] (1) Clean the silicon wafer and make the surface texture;

[0025] (2) Perform phosphorus diffusion to form a PN junction;

[0026] (3) Etching, dephosphorous silicon glass cleaning;

[0027] (4) Form a passivation layer on the front surface by PECVD or magnetron sputtering;

[0028] (5) A single-layer passivation layer is formed on the back surface by thermal oxidation, and the structure of the passivation layer is SiO 2 (The passivation layer can also be a-Si, SiC, SiNx, etc.), with a thickness of 20nm;

[0029] (6) Utilize the method of ink-jet printing corrosive paste, open contact window on the back passivation layer, the technological process of opening contact window on the surface of solar cell back passivation layer is: adopt the method for ink-jet printing to passivate on the back side Print corrosive slurry on the layer, the wet weigh...

Embodiment 2

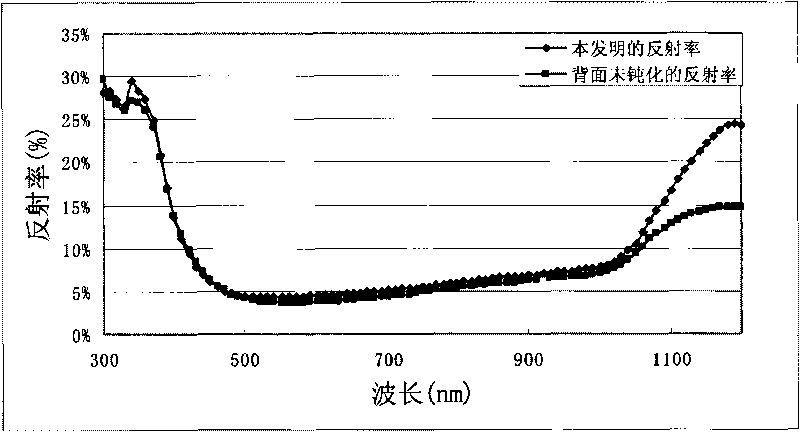

[0035] See attached figure 2 Shown, a kind of preparation method of crystalline silicon solar cell comprises the steps:

[0036] (1) Clean the silicon wafer and make the surface texture;

[0037] (2) Perform phosphorus diffusion to form a PN junction;

[0038] (3) Etching, dephosphorous silicon glass cleaning;

[0039] (4) Form a passivation layer on the front surface by PECVD or magnetron sputtering;

[0040] (5) A single-layer passivation layer is formed on the back surface by PECVD, and the structure of the passivation layer is SiO 2 (The passivation layer can also be a-Si, SiC, SiNx, etc.), with a thickness of 50nm;

[0041] (6) Utilize the method of ink-jet printing corrosive paste, open contact window on the back passivation layer, the technological process of opening contact window on the surface of solar cell back passivation layer is: adopt the method for ink-jet printing to passivate on the back side Print corrosive slurry on the layer, the wet weight of corros...

Embodiment 3

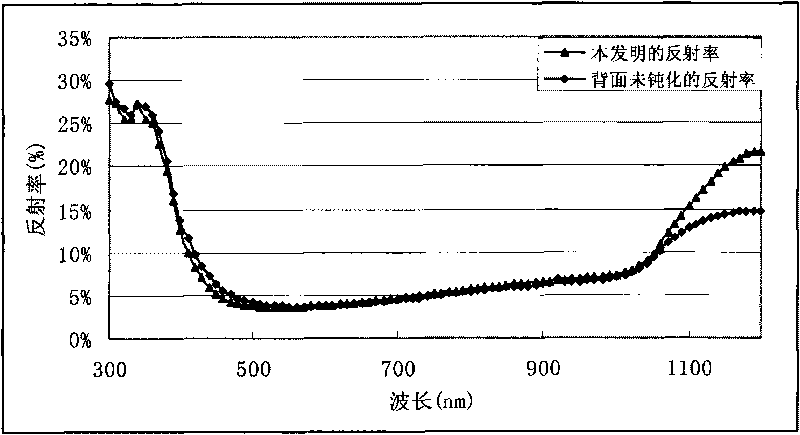

[0047] See attached image 3 Shown, a kind of preparation method of crystalline silicon solar cell comprises the steps:

[0048] (1) Clean the silicon wafer and make the surface texture;

[0049] (2) Perform phosphorus diffusion to form a PN junction;

[0050] (3) Etching, dephosphorous silicon glass cleaning;

[0051] (4) Form a passivation layer on the front surface by PECVD or magnetron sputtering;

[0052] (5) Utilize the PECVD method to form a single-layer passivation layer on the back surface, the structure of the passivation layer is SiNx (the passivation layer can also be a-Si, SiC, SiO 2 etc.), the thickness is 60nm;

[0053] (6) Utilize the method of ink-jet printing corrosive paste, open contact window on the back passivation layer, the technological process of opening contact window on the surface of solar cell back passivation layer is: adopt the method for ink-jet printing to passivate on the back side Print corrosive slurry on the layer, the wet weight of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com