Biocoke producing apparatus, method of controlling the same and process for production thereof

A technology for production equipment and biochar, applied in the direction of biofuel, manufacturing tools, products, etc., can solve the problems of low calorific value, small apparent specific gravity, insufficient particle hardness, etc., and achieve the effect of shortening the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

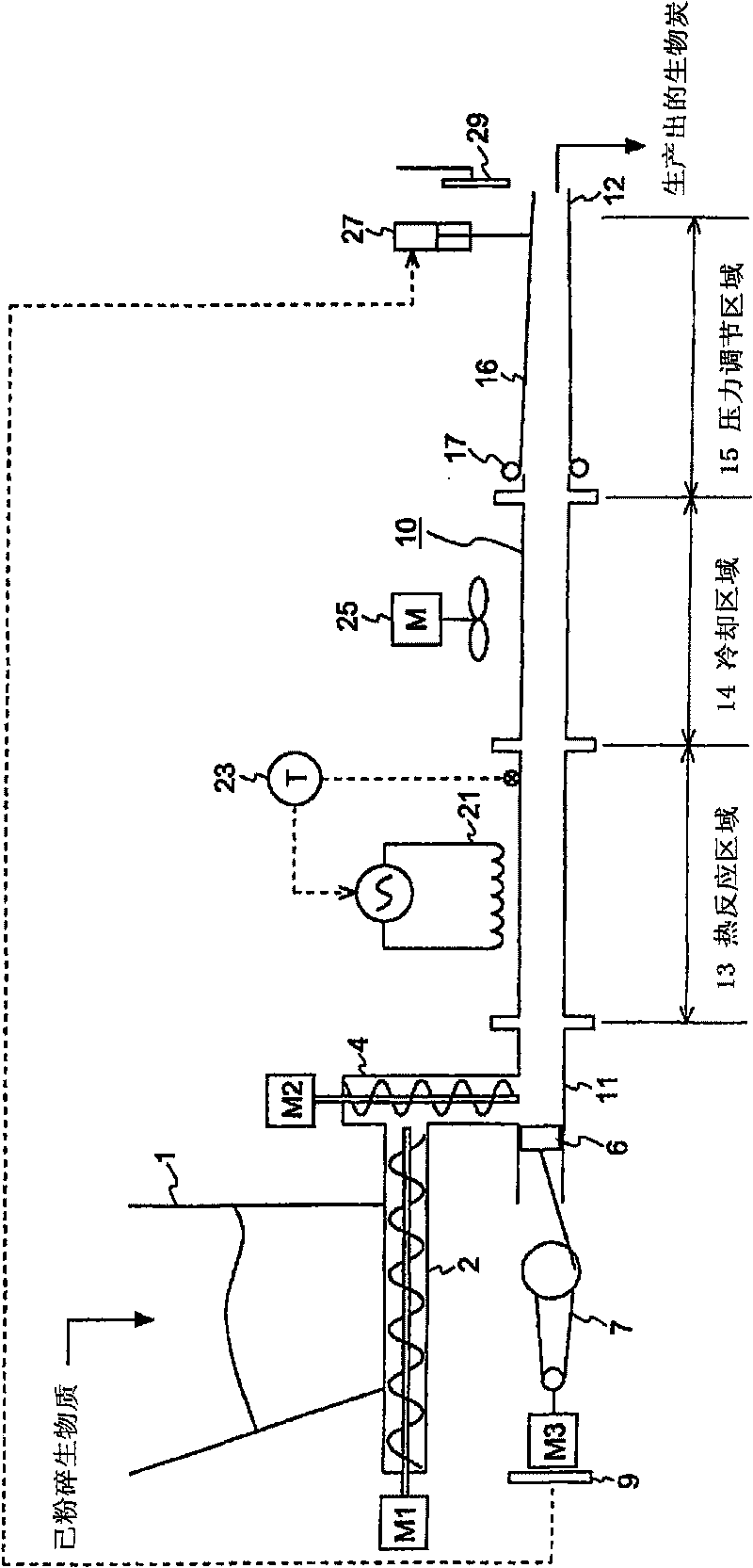

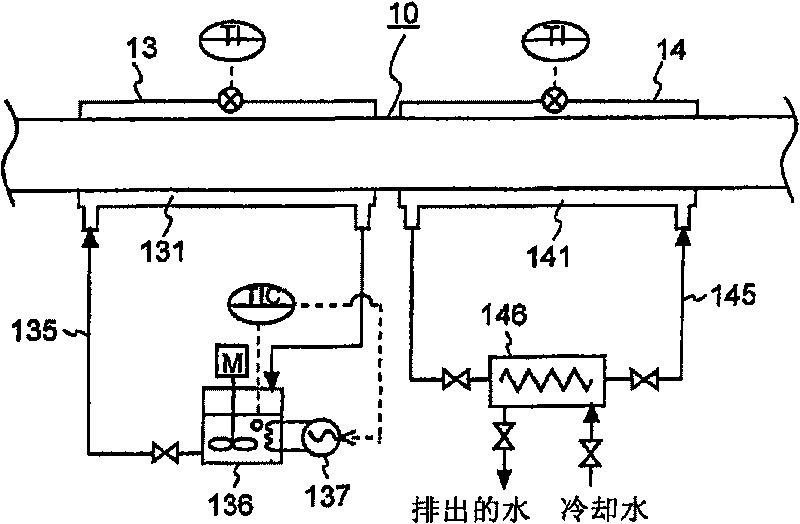

[0058] In an embodiment, not only the water content of the biomass is adjusted, but also the biomass is pretreated to be pulverized into a predetermined particle size or smaller, thereby using the pulverized biomass as a raw material. The biocoke production apparatus of the present invention produces biocoke by cooling the pulverized biomass by pressurizing and heating the pulverized biomass under predetermined pressure and heat conditions, and then maintaining the conditions for a certain period of time. The above-described conditions for pressurization and heating are set within the range of inducing pyrolysis or thermal curing reactions of hemicellulose and lignin contained in the pulverized biomass. Specifically, the pressure and temperature are set within a range in which pyrolysis or thermal curing reactions of hemicellulose and lignin contained in the pulverized biomass are induced.

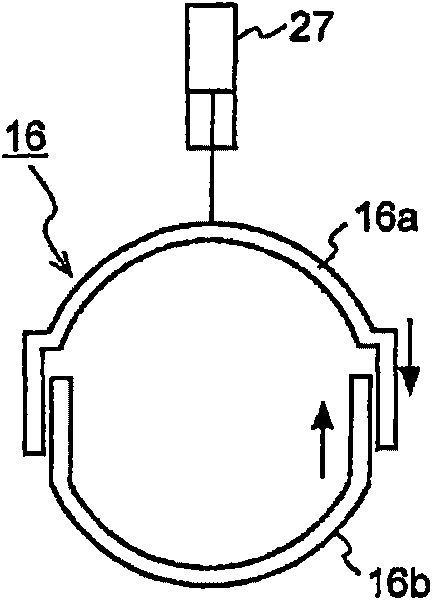

[0059] refer to figure 1 To illustrate the overall structure of the biochar producti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com