Membrane oxygenation type container for transporting aquatic living bodies

A living body transportation and aquatic product technology, which is applied in fish farming, application, animal husbandry, etc., can solve the problems of low dissolved oxygen efficiency, low oxygen solubility, and aquatic product death, so as to improve the dissolved oxygen efficiency and facilitate the stacking of boxes , to avoid the effect of water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

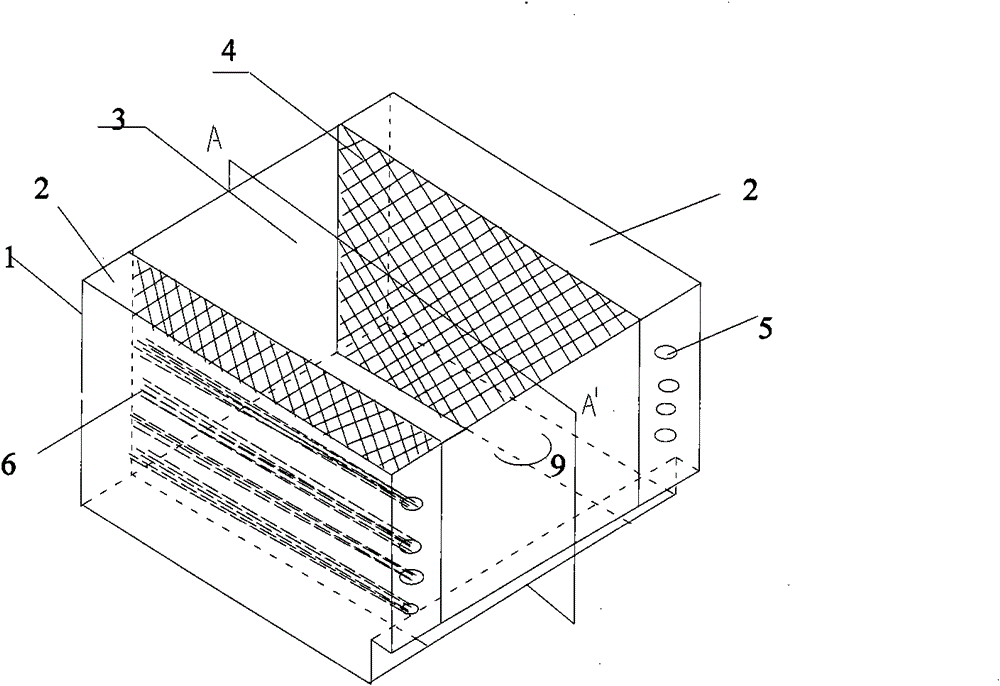

[0023] Such as figure 1 As shown, the box body 1 mainly includes an oxygen supply area 2 and a fish culture area 3, and the oxygen supply area 2 and the fish culture area 3 are separated by an inner partition 4, wherein the inner wall of the box body 1 is provided with a card slot, and the inner partition 4 is inserted into the draw-in slot, and the inner dividing plate 4 is a 0.4 mesh movable plate that can be freely disassembled. The oxygen supply area 2 is located on the side of the box body 1, and 15 hollow fibers 6 are laid in the oxygen supply area 2. The hollow fibers 6 are sealed and connected with the air inlet holes 5 on the side wall of the box body 1. One end of the hollow fiber penetrates into the air inlet 5 to connect with the external oxygen supply pipeline, and a fixed sealing device is arranged between the outer wall of the hollow fiber 6 and the air inlet 5 .

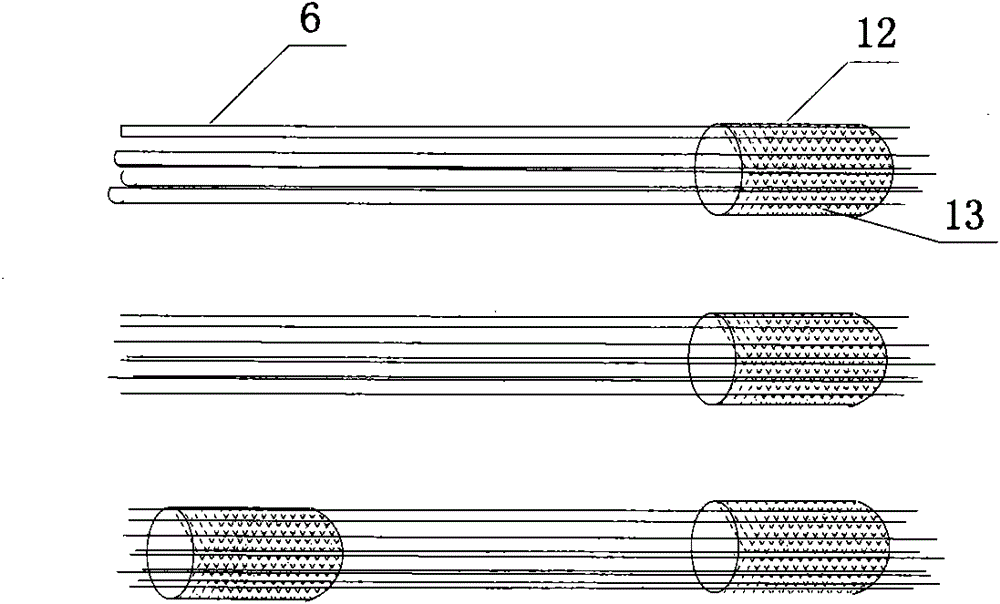

[0024] Such as figure 2 As shown, the fixed sealing device includes a hollow small sleeve 12 an...

Embodiment 2

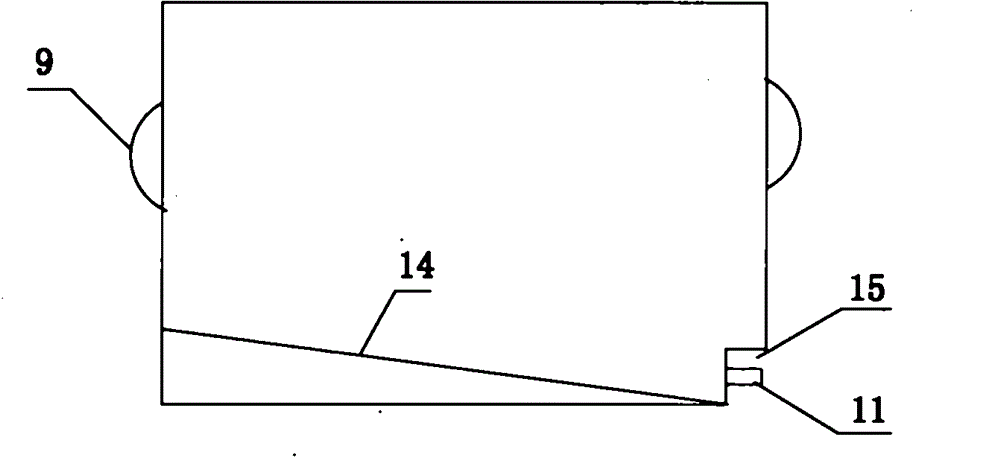

[0031] With embodiment 1, its difference is: the hollow fiber 6 that lays in the oxygen supply area 2 is 30; The oxygen pipelines are connected, and the other end is sealed by gluing; the horizontal angle of the movable plate 14 is 20°.

[0032] A transport container with a volume of 8L is used to transport 50 juvenile light-colored croakers. According to the oxygen consumption rate of larval croakers, the oxygen consumption rate is 0.15-0.62mgO 2 / h·g fish weight, adjust the polyethersulfone hollow fiber laying density to be 320mm per liter of water body membrane surface area 2 , its pore diameter is 0.3 microns, the air supply pressure is 0.12atm (absolute pressure), the simulated transportation experiment is carried out, the transportation time is 56h, and the survival rate of the light-colored yellow croaker juveniles is above 95%.

Embodiment 3

[0034] With embodiment 1, its difference is: the hollow fiber 6 that lays in the oxygen supply area 2 is 100; The oxygen pipeline is connected, and the other end is connected with the air outlet pipe through a small hollow plastic sleeve; the horizontal angle of the movable plate 14 is 40°.

[0035] A transport container with a volume of 10L transports 20 yellow catfish, according to the oxygen consumption rate of the yellow catfish 0.20~0.87mgO 2 / h g fish weight, adjust the polyvinylidene fluoride hollow fiber membrane laying density per liter of water membrane surface area of 490mm 2 , its pore diameter is 0.4 micron, the air supply pressure is 0.13atm (absolute pressure), the simulated transportation experiment is carried out, the transportation time is 48h, and the survival rate of the yellow catfish is more than 93%.

[0036] The material of the hollow fiber can be polyethylene, polytetrafluoroethylene, polysulfone, polyvinyl chloride, polycarbonate, polyacrylonitrile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com