Box-structure submerged arc and gas-shielded dual-purpose welding machine of thin wire

A box-shaped structure and filament technology, which is applied in the field of gas-shielded dual-purpose welding machines and filament submerged arc, can solve the problems of not being suitable for the production and manufacture of heavy steel structures, insufficient gas protection, and affecting the quality of welds, etc., to achieve improved The effect of equipment utilization, saving flux and improving weld quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

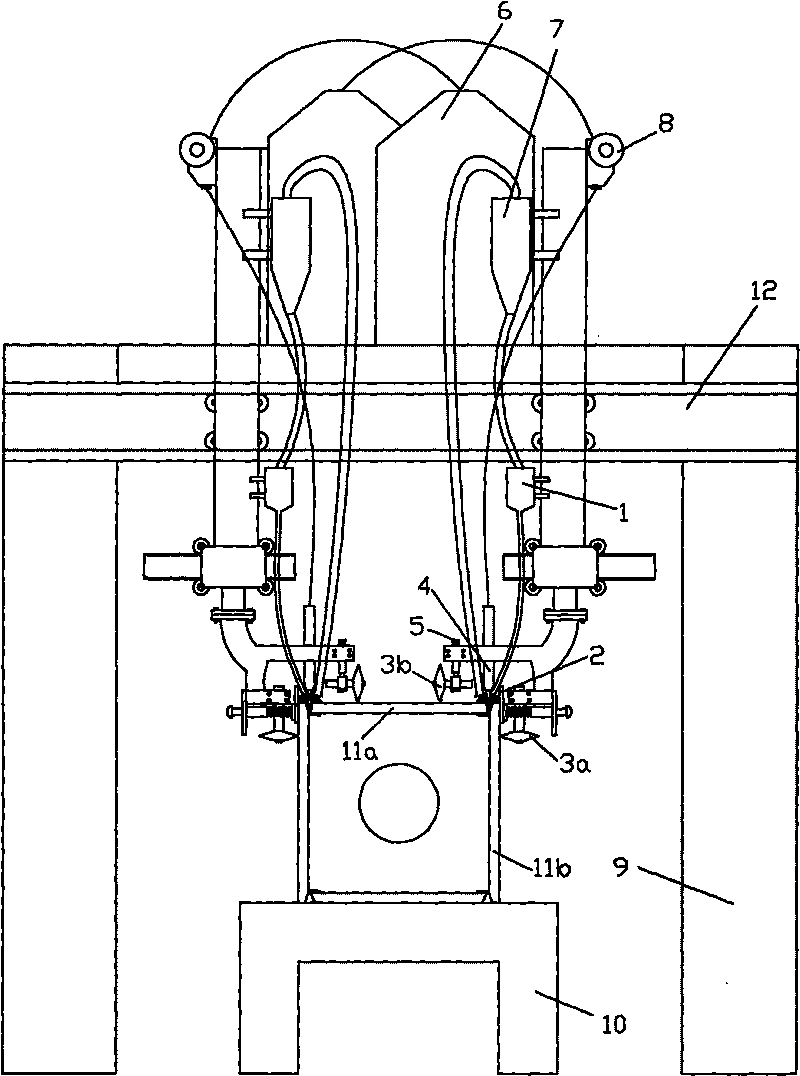

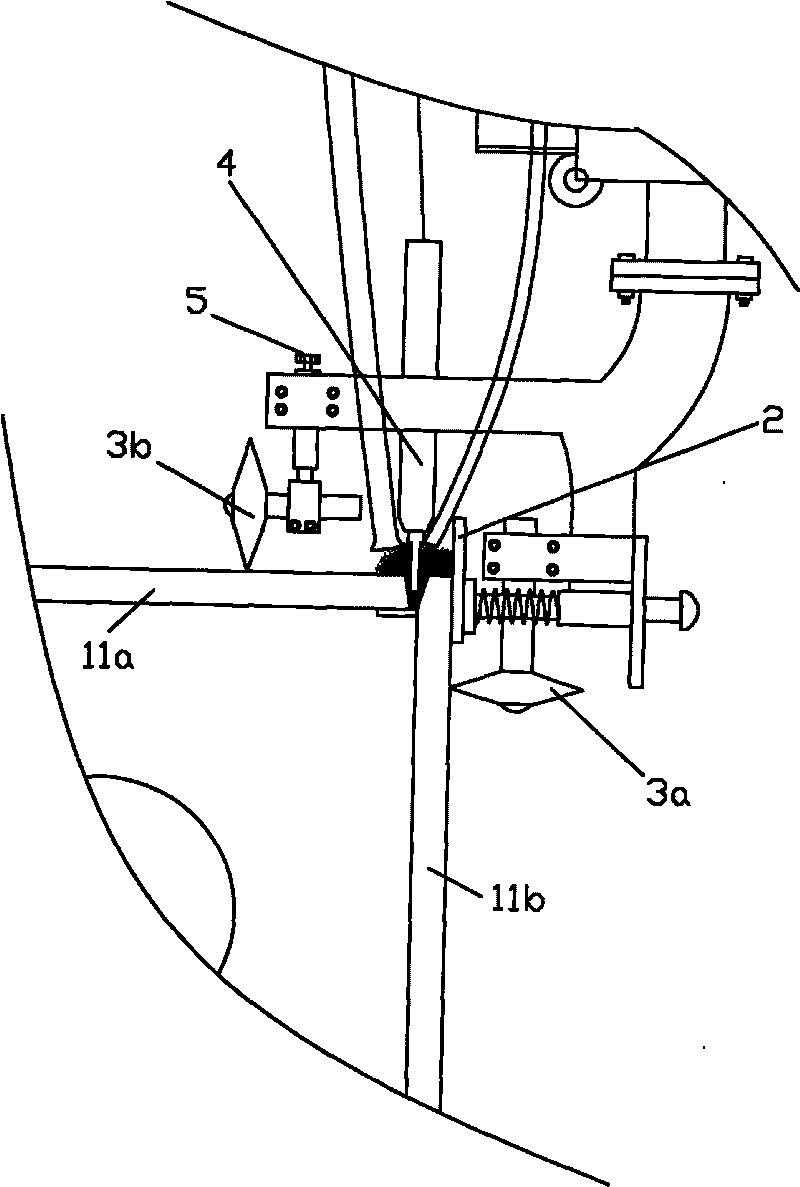

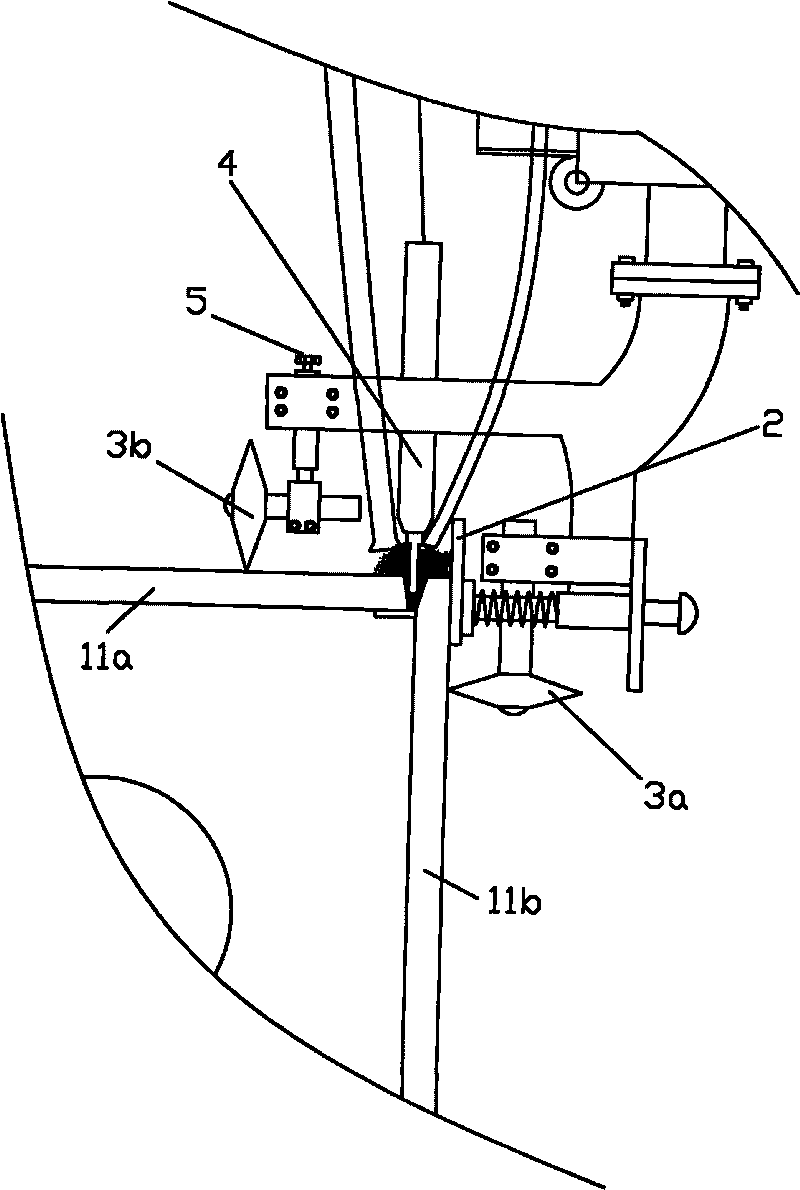

[0019] see figure 1 , the present embodiment adopts the existing gas shielded welding machine, and the portal frame composed of the door post 9 and the track beam 12 is left and right symmetrically arranged in the portal frame and fixed on the frame. The horizontal guide roller 3a on the outside of the welded box profile, the longitudinal guide roller 3b positioned at the top of the box profile to be welded, the welding torch fixture arranged on the roller bracket, the welding torch 4 clamped in the welding torch fixture is directed towards the The welding groove between the plate 11a and the box wing 11b; in this embodiment, on the outside of the box wing 11b, a flux baffle 2 that can lean against the box wing is set, and the flux baffle The upper edge of the plate 2 is higher than the web 11a of the box-shaped part; the welding torch 4 is a replaceable submerged arc welding torch or a gas-shielded welding torch held in a welding torch fixture, and the submerged arc welding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com