Method for accelerating sludge settling, concentrating and dehydrating by vibration

A technology of sludge precipitation and sludge concentration, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of a lot of costs, inability to achieve sanitary landfill and incineration of sludge, and spending a lot of time and space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

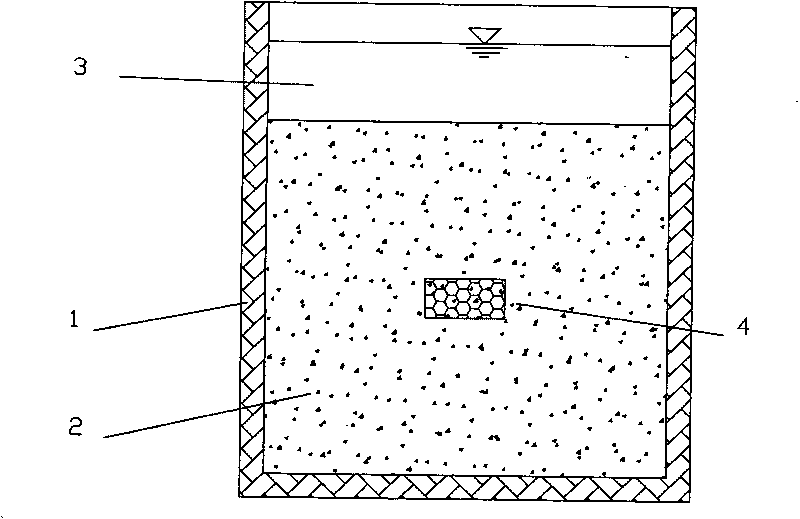

[0013] exist figure 1 The sludge sedimentation, concentration and dehydration tank 1 is added with a vibrating device 4, 3 is the supernatant, and the vibrating device 4 composed of a drive motor drives a vibrator to generate a vibration force. The vibration force and gravity work together to accelerate the sludge 2. Precipitation, concentration, dehydration.

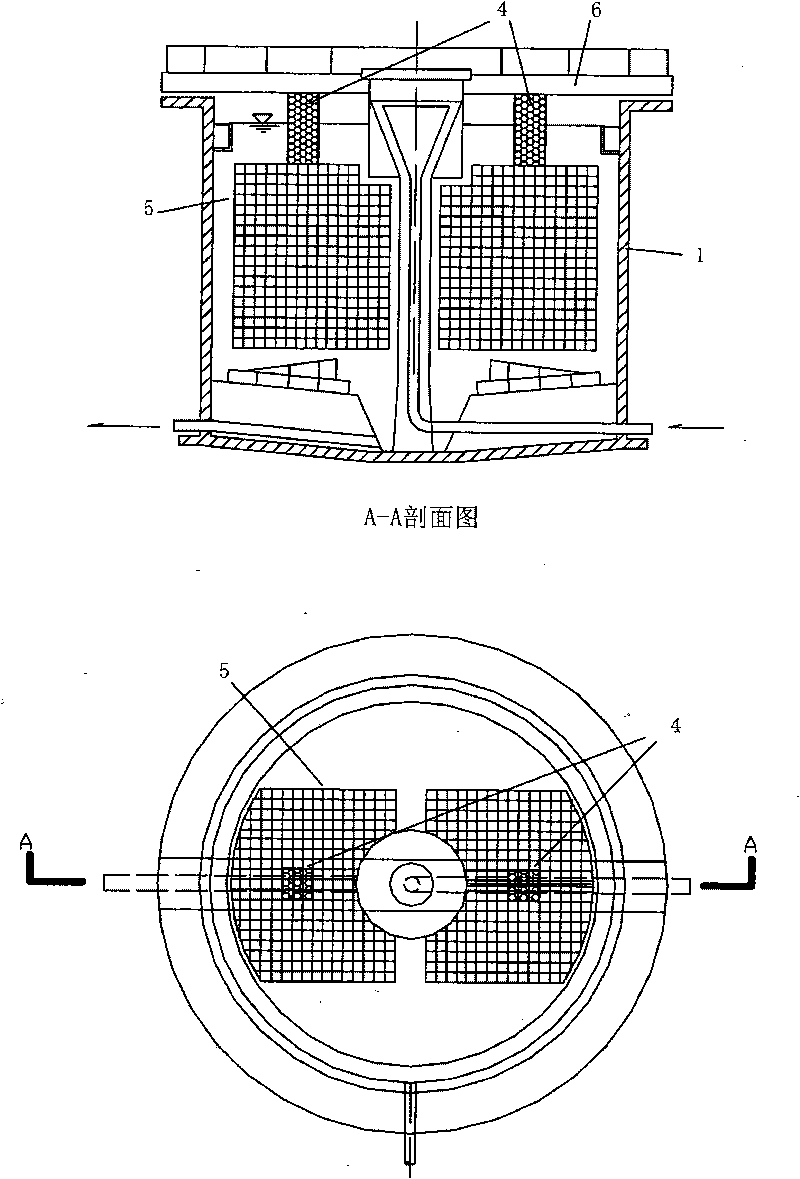

[0014] exist figure 2 In the actual sludge thickening tank 1, it is assumed that the diameter of the sludge thickening tank is 20 meters, and the height is 6 meters. Rotary mud scraping equipment is installed in the sludge thickening tank. In the pool body, rods made of metal, organic polymer materials or wood are used to connect the three-dimensional grid structure 5. The three-dimensional grid structure is divided into two parts, each part is 8.0 meters long, 3 meters high, and 2 meters wide. The three-dimensional grid structure The distance between the middle pole and the pole is 0.5 meters. The three-dimensional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com