Rubber composition for base tread and tire

一种橡胶组合物、胎面基部的技术,应用在特殊轮胎、轮胎零部件、车辆部件等方向,能够解决低燃料消耗、没有具体地研究胎面基部等问题,达到出色耐久性、出色加工性能和燃料经济性、抑制返硫现象的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

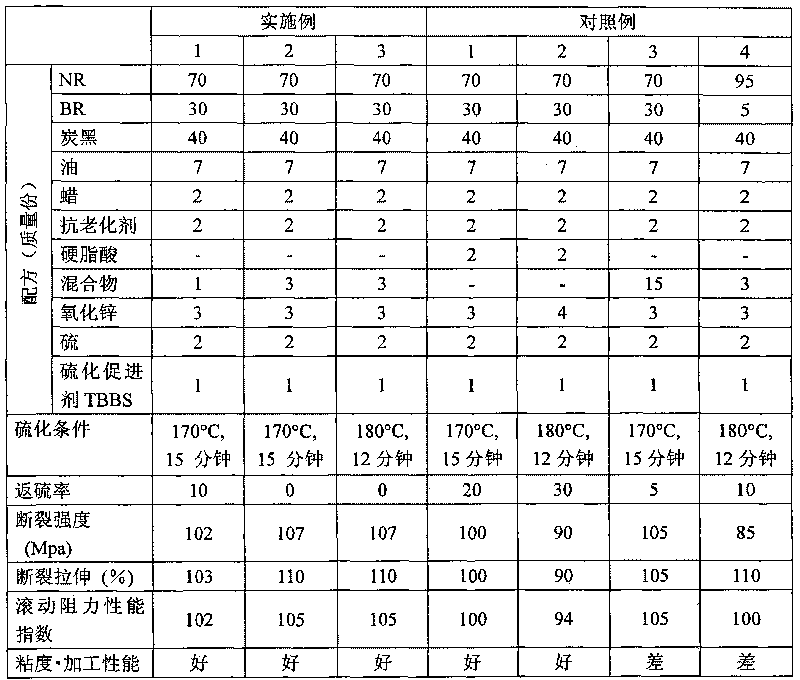

[0045] Next, the present invention will be specifically described based on examples, but the present invention is not limited to these examples.

[0046] The respective chemicals used in Examples and Comparative Examples are listed below.

[0047] NR: RSS #3.

[0048] BR: BR150B, manufactured by Ube Industries, Ltd.

[0049] Carbon black: N330 (N 2 SA: 88m 2 / g, average particle diameter: 31 nm, DBP oil absorption: 105 ml / 100 g), manufactured by Showa Cabot K.K. Co., Ltd.

[0050] Oil: Process Oil PW-32, manufactured by Idemitsu Kosan Co., Ltd.

[0051] Wax: SUNNOC Wax, manufactured by Ouchi Shinko Chemical Industry Co., Ltd.

[0052] Antiaging agent: NOCRAC 6C (N-(1,3-dimethylbutyl)-N'-phenyl-p-phenylenediamine), manufactured by Ouchi Shinshin Chemical Industry Co., Ltd.

[0053] Stearic acid: stearic acid, manufactured by NOF Corporation.

[0054] Mixture (mixture of zinc salt of aliphatic carboxylic acid and zinc salt of aromatic carboxylic acid): Activator 73A, manu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com