Method for comprehensively utilizing high-iron biological copper leaching liquid

A bioleaching and biological technology, applied in the direction of improving process efficiency, can solve the problem that copper cannot be recycled, and achieve the effect of saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Add 2L of biological immersion copper solution into a 2L three-necked bottle, start stirring, heat to 85°C, add 200g of sodium thiosulfate, react for 60min and then filter. The compositions of the bioheap leaching solution and the post-reaction heap leaching solution are shown in Table 1 and Table 2, respectively, and the components of the obtained sediment are shown in Table 3.

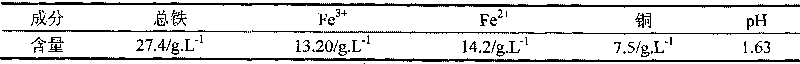

[0015] Table 1 Main components of biological copper leaching solution

[0016]

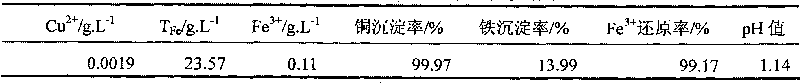

[0017] Table 2 sodium thiosulfate treatment biological leaching copper solution result /

[0018]

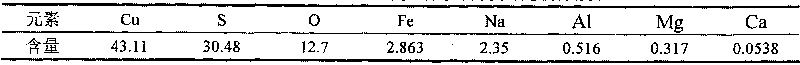

[0019] Table 3 Sodium thiosulfate treatment of biological leaching copper solution obtained sediment composition / %

[0020]

Embodiment 2

[0022] Pass hydrogen sulfide into 4L of biological leaching copper solution, stir and react at room temperature for 30min, and then filter to obtain 3.85L of filtrate. The composition of the biological leaching copper solution is shown in Table 4, the composition of the biological leaching copper solution after hydrogen sulfide treatment is shown in Table 5, and the obtained precipitation components are shown in Table 6.

[0023] Table 4 Composition of biological leaching copper solution / g L -1

[0024]

[0025] Table 5 Composition of biological leaching copper solution after hydrogen sulfide treatment / g L -1

[0026]

[0027] It can be seen that the copper precipitation rate is 100%, the iron precipitation rate is 24.4%, the iron reduction rate is 95.2%, and the pH value after the reaction is 0.73.

[0028] Table 6 Hydrogen sulfide treatment obtained precipitation components / %

[0029]

[0030] It can be seen from Table 6 that the precipitates obtained after hydr...

Embodiment 3

[0032] 315g sodium sulfide (Na 2 S·9H 2 O) adding 4L of the above-mentioned biological immersion copper solution, stirring and reacting at room temperature for 30min and then filtering. The components of the biological copper leaching solution after sodium sulfide treatment are shown in Table 7, and the components of the obtained precipitate are shown in Table 8.

[0033] Table 7 Sodium sulfide treatment results of biological leaching copper solution / g L -1

[0034]

[0035] Table 8 Sodium sulfide treatment of biological leaching copper solution obtained precipitation components / %

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com