High-speed electromagnetic valve driver circuit

A high-speed solenoid valve and drive circuit technology, applied in transformer/inductor circuits, valve details, valve devices, etc., can solve the problems of bootstrapping booster circuits not being able to bootstrap normally, increasing circuit complexity, and burning MOS tubes. To achieve the effect of increasing complexity, reducing reliability, improving efficiency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

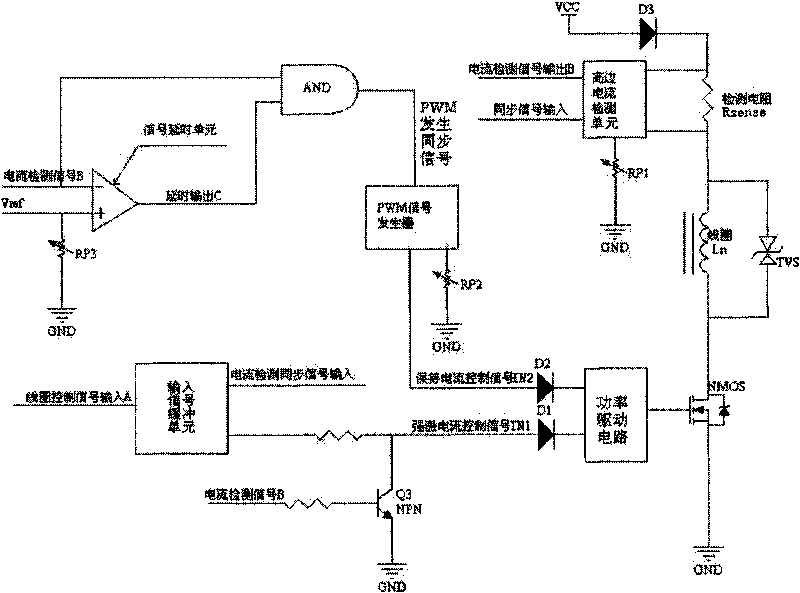

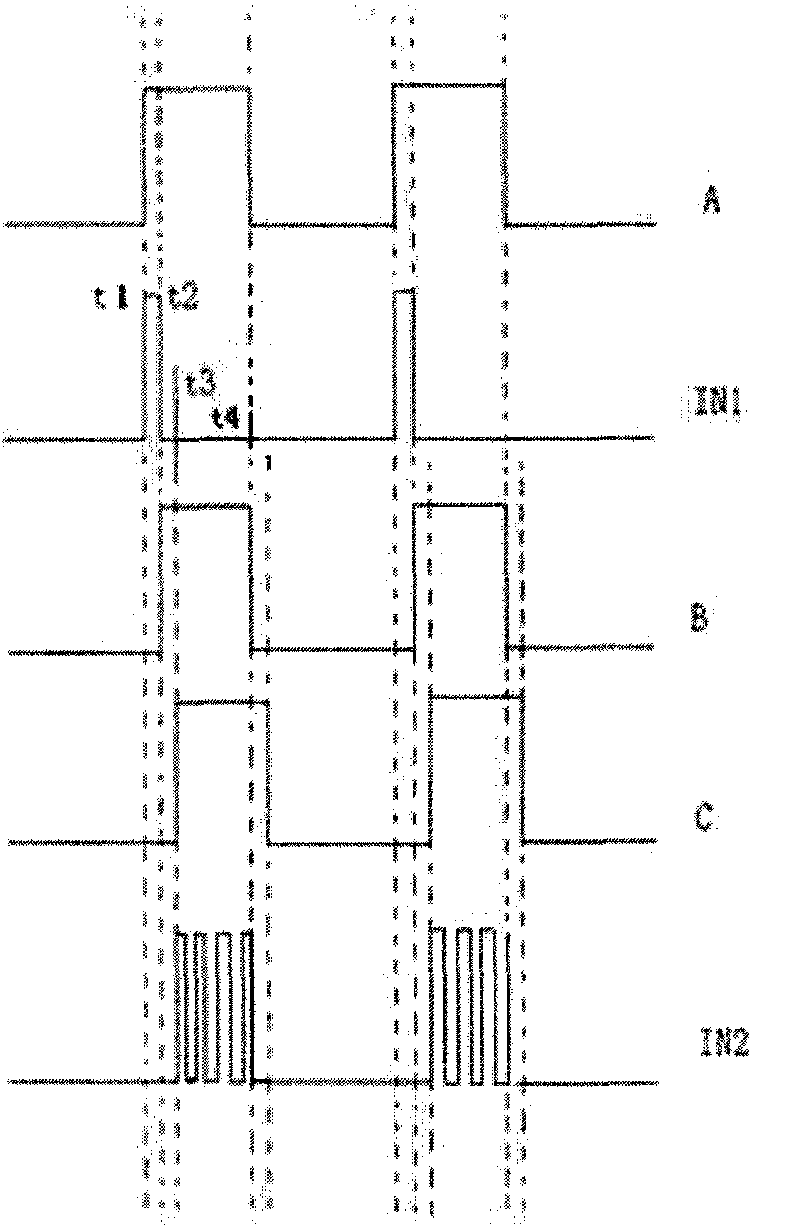

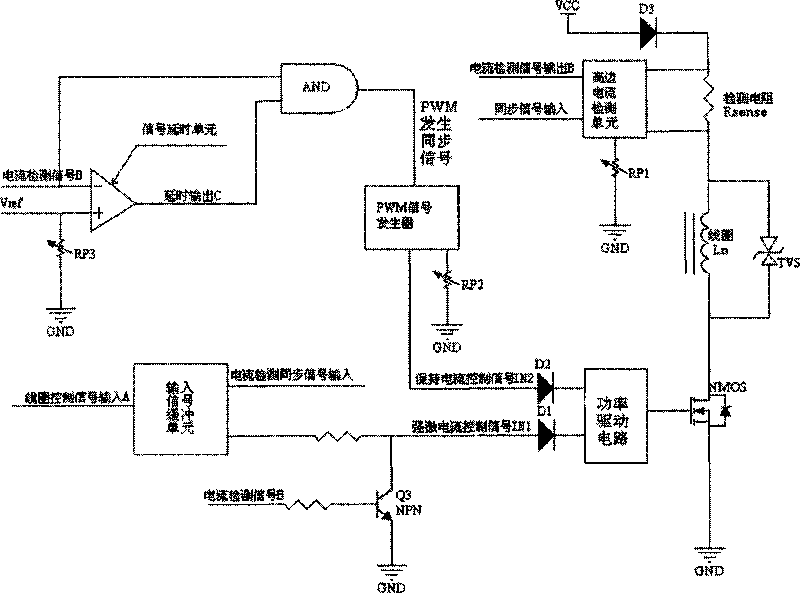

[0018] This circuit is mainly a high-speed solenoid valve drive circuit (this drive circuit can be used as a supporting drive circuit for the valve in the application number 200910090745.0 "Electromagnet and Switch Valve Using the Electromagnet"). According to the working principle, the solenoid valve core can be used Spring return can also use dual coils to push and pull the spool. Since the valve is a high-speed solenoid valve, its opening and closing time reach 1ms respectively, so its current response characteristics determine that its driving circuit should meet the following basic requirements. 1. The energy-intensive power before the solenoid valve is opened should inject energy into the solenoid valve at the highest possible rate to ensure that the solenoid control valve generates a sufficient electromagnetic force during the opening process and shorten the opening response time; 2. The solenoid valve is opened Finally, because the working air gap is small and the relu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com