Fluorescent powder packaging of light-emitting diode

A technology of light-emitting diodes and phosphors, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of uneven color, unstable quality, and the inability to precisely control the fluorescent cubes of phosphors, so as to simplify the packaging process, The effect of high color uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to facilitate your examiners to have a further understanding of the technical means and operation process of the present invention, an embodiment is now given with the accompanying drawings, and the detailed description is as follows.

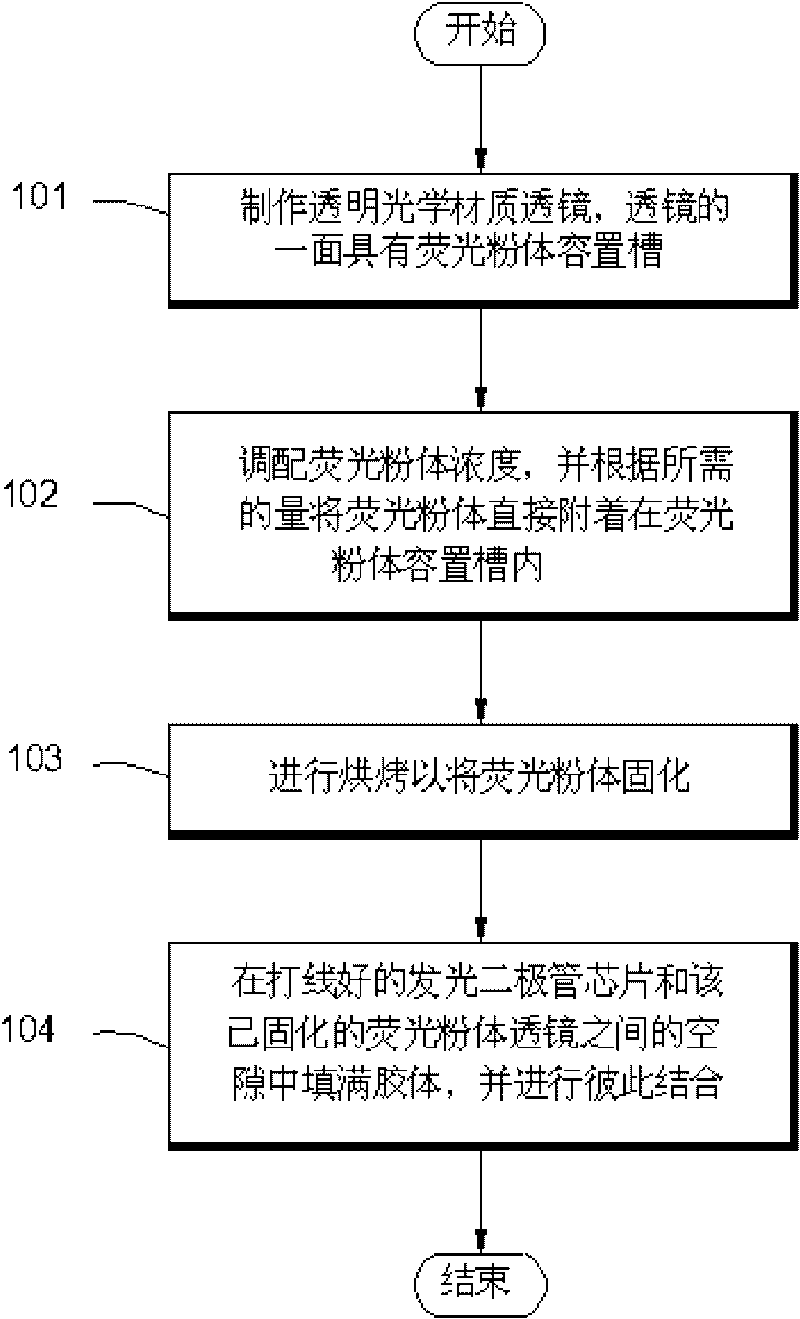

[0018] The present invention is a kind of fluorescent powder package of light-emitting diode, because the coating shape, concentration and uniformity of fluorescent powder have great influence on the quality (such as: light extraction efficiency, color temperature and color uniformity, etc.) ) has a great influence, therefore, in order to accurately control the parameters such as the position, shape, size, concentration, uniformity and thickness of the light-emitting diode during phosphor packaging, the present invention provides the phosphor packaging process of the light-emitting diode shown below , its processing steps refer to figure 1 Shown:

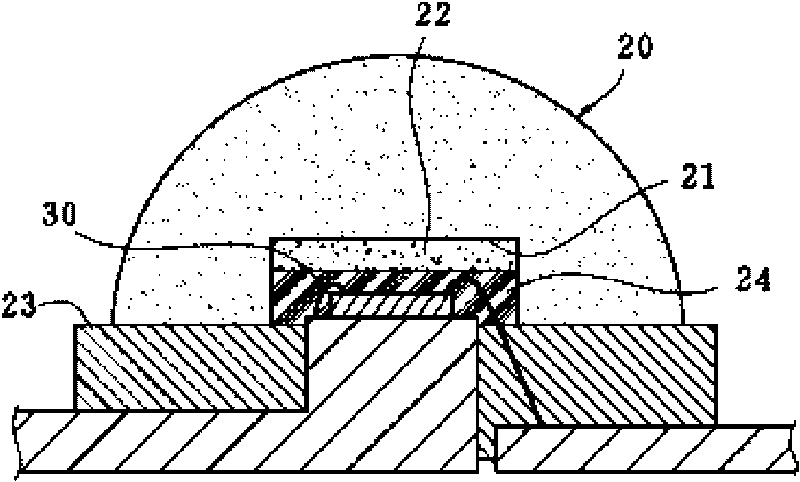

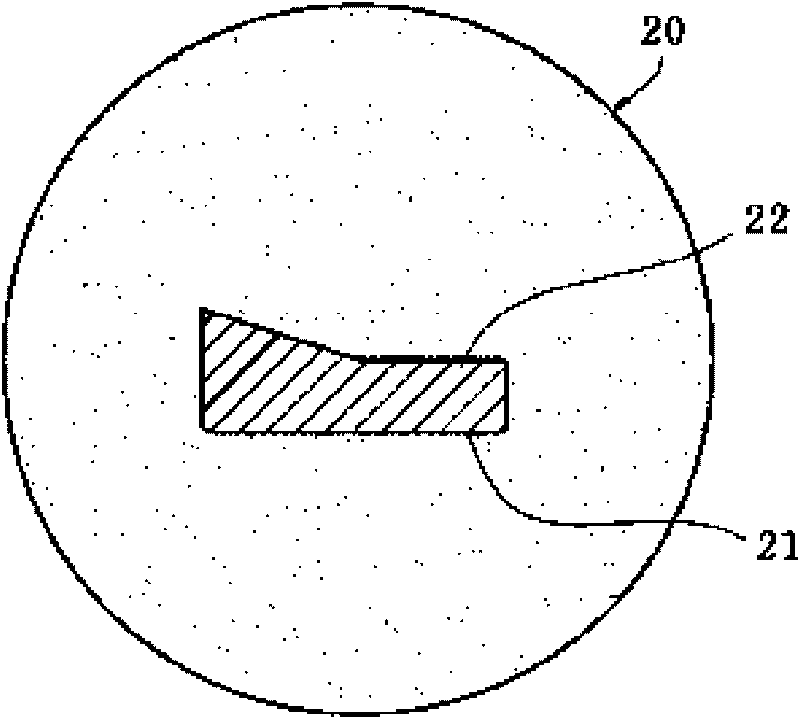

[0019] Step 101: First, use a transparent optical material to make a lens, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com