High-power V-shaped plasma torch

A plasma torch, high-power technology, applied in the field of ion torches, can solve the problems of low power, short running time, plasma torch electrode ablation, etc., and achieve the effects of low energy consumption and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

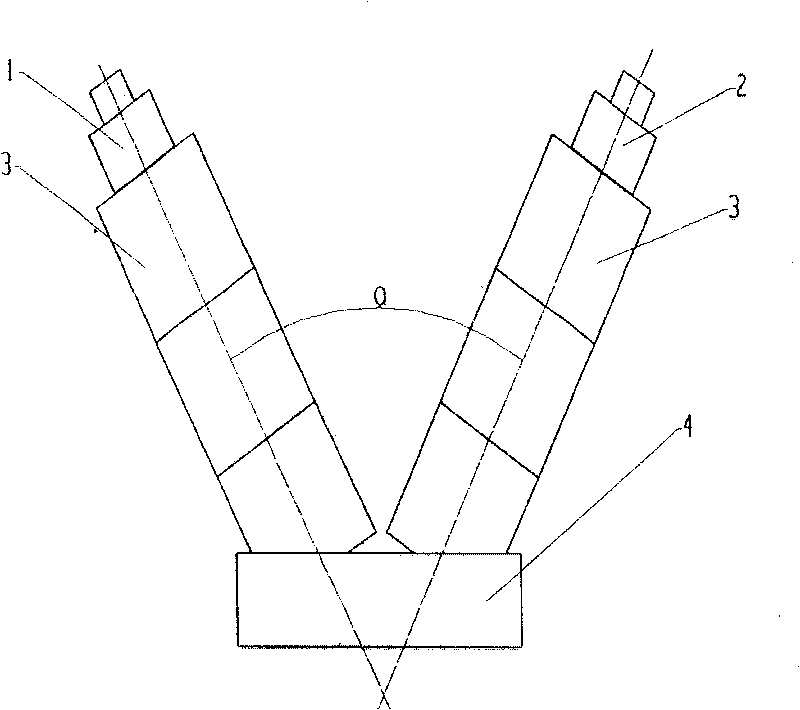

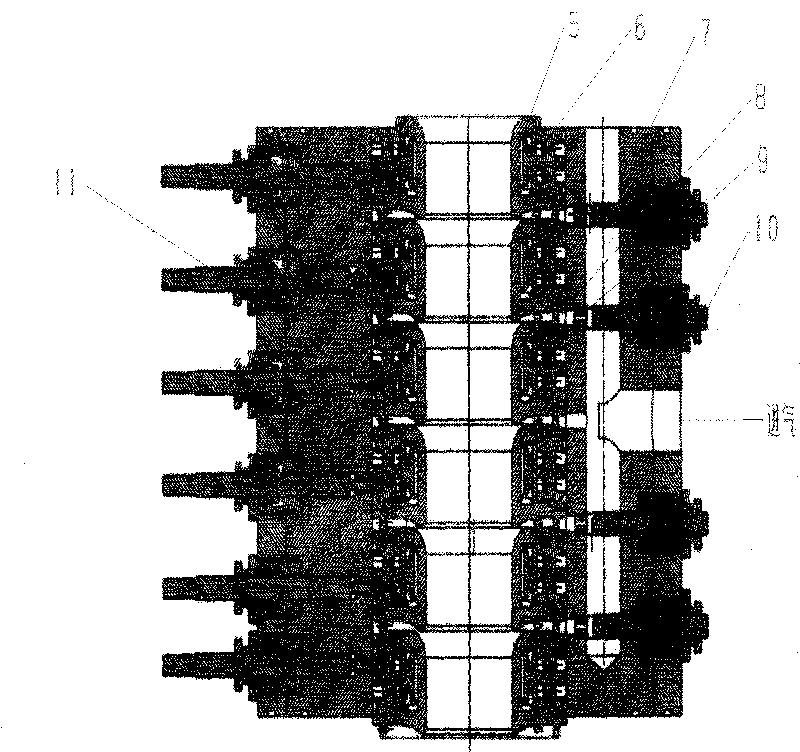

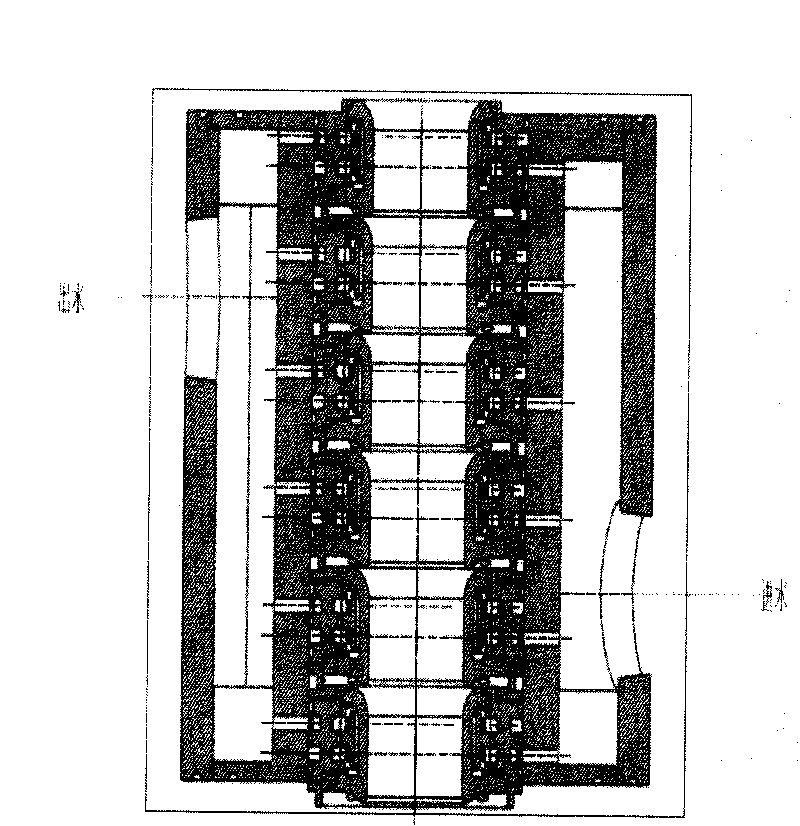

[0022] Embodiment 2 of the present invention is to combine two or more V-shaped plasma generators together to form a plasma generating device. The combination method is to arrange two or more V-shaped hydrogen plasma generators at a certain angle, each The plasma formed by the plasma torch converges at a certain distance below the plasma torch to form a plasma generating device with higher power. This embodiment can increase the power of the plasma torch in a wide range, and is suitable for coal, oil Cracking, metallurgy, waste treatment and other processes.

Embodiment 3

[0023] Embodiment 3 differs from Embodiment 1 or 2 in that: the angle between the cathode arm and the anode arm of the high-power V-shaped plasma torch is 50°.

Embodiment 4

[0024] Embodiment 4 differs from Embodiment 1 or 2 in that: the angle between the cathode arm and the anode arm of the high-power V-shaped plasma torch is 100°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com