Plasma generating device

A generating device and plasma technology, applied in the direction of plasma, separation method, dispersed particle separation, etc., can solve the problems of large power consumption and high cost, and achieve the effect of reducing energy consumption, low operating cost, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

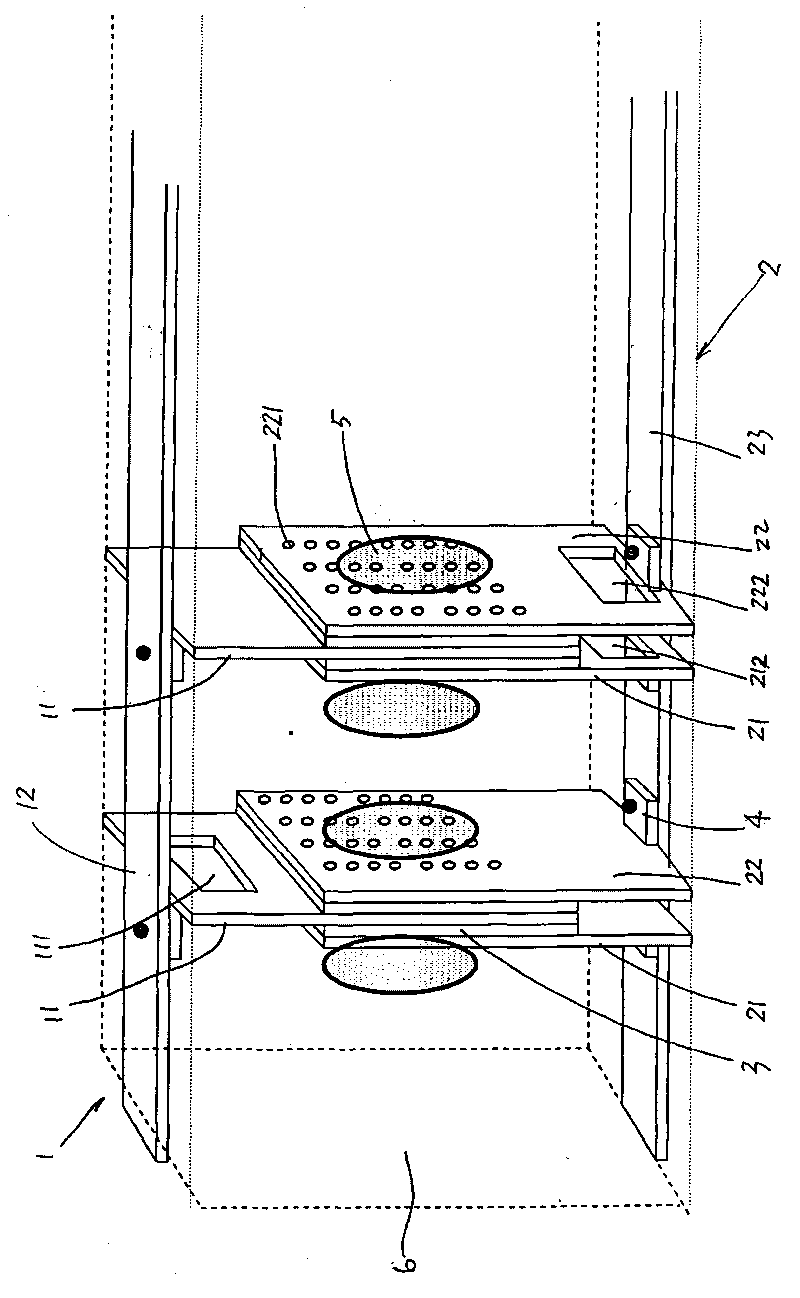

[0044] see figure 1As shown in the structural diagram of Embodiment 1 of the present invention, a plasma generating device is used for gas treatment. The plasma generating device is arranged in a gas flow channel 6 that is closed around and open at both ends. The first electrode 1 is formed by the first A common electrode 12 is connected with two or more first electrode units arranged side by side (only two are shown in the figure), and the first electrode unit is composed of a metal sheet 11;

[0045] The second electrode 2 is composed of a second common electrode 23 and two or more second electrode units arranged side by side (only two are shown in the figure), and each electrode unit is composed of two metal sheets 21 , 22 constitute;

[0046] A metal sheet 11 of each first electrode unit overlaps two metal sheets 21, 22 of the second electrode unit alternately on both sides, and the first electrode 1 and the second electrode 2 are separated by an insulating layer 3 at the...

Embodiment 2

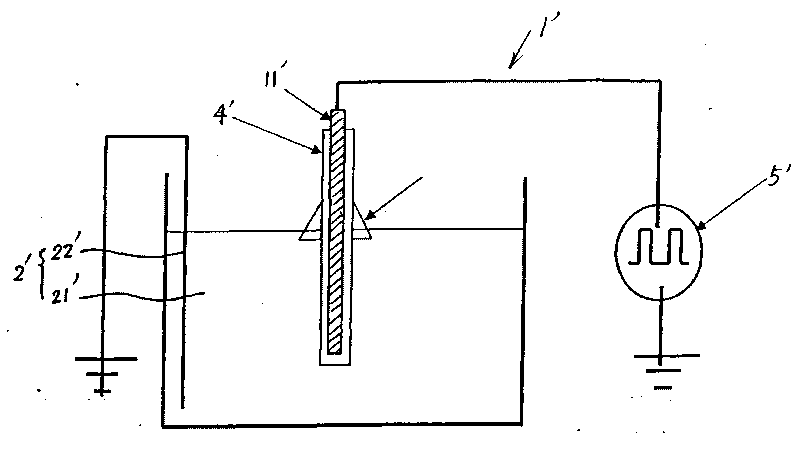

[0054] see figure 2 As shown in the schematic diagram of the structure of Embodiment 2 of the present invention, a new type of plasma generating device includes two electrodes, and the first electrode 1' is an electrode unit composed of an insulating layer 3' coated with a metal rod 11', which is insulated Layer 3' is an insulating material (glass) cladding layer, and a liquid (water) 21' inserted with a grounding conductor 22' is used as a second electrode 2', wherein the lower part of the first electrode 1' is inserted into the electrode 2' And the insertion part is not less than 2mm, so that the upper part of the first electrode 1 is exposed to the air, the first electrode 1' and the second electrode 2' are connected and separated by an insulating layer 3', and the wall thickness of the insulating layer is not more than 0.5 mm, the covering area of the insulating layer 3' is larger than the entire insertion part of the first electrode 1';

[0055] Under normal temperatu...

Embodiment 3

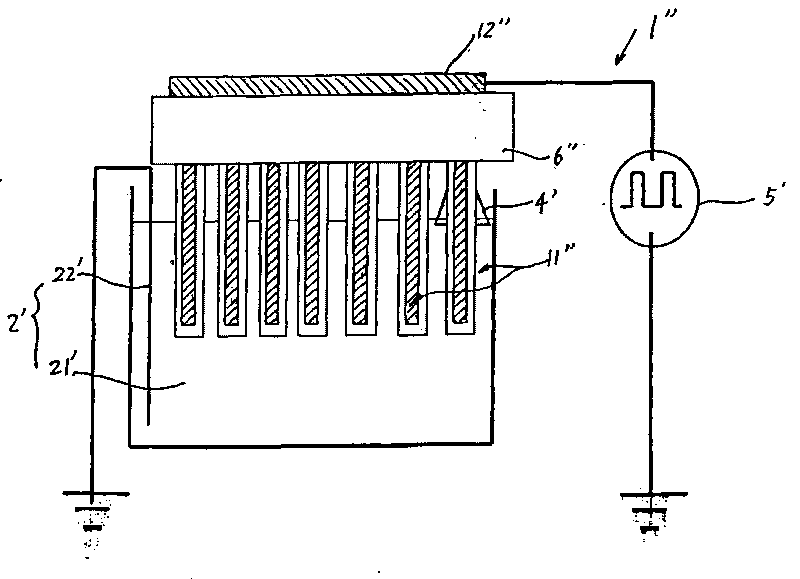

[0059] see image 3 As shown in the schematic diagram of the structure of Embodiment 3 of the present invention, the first electrode 1" is composed of a common electrode 12" and seven electrode units 11". The structure of the electrode units 11" is the same as that of Embodiment 2, except that the first The electrode 1' is composed of seven first electrode units 1" connected in parallel on the electrode support 6".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com