Light gas pipeline

A gas pipeline and pipeline technology, applied in tracks, roads, tunnel systems, etc., can solve the problems of inability to eliminate the influence of air resistance ultra-high-speed transport vehicles, technical difficulties, insecurity, etc., to achieve energy saving, rich material resources, Easy-to-build effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

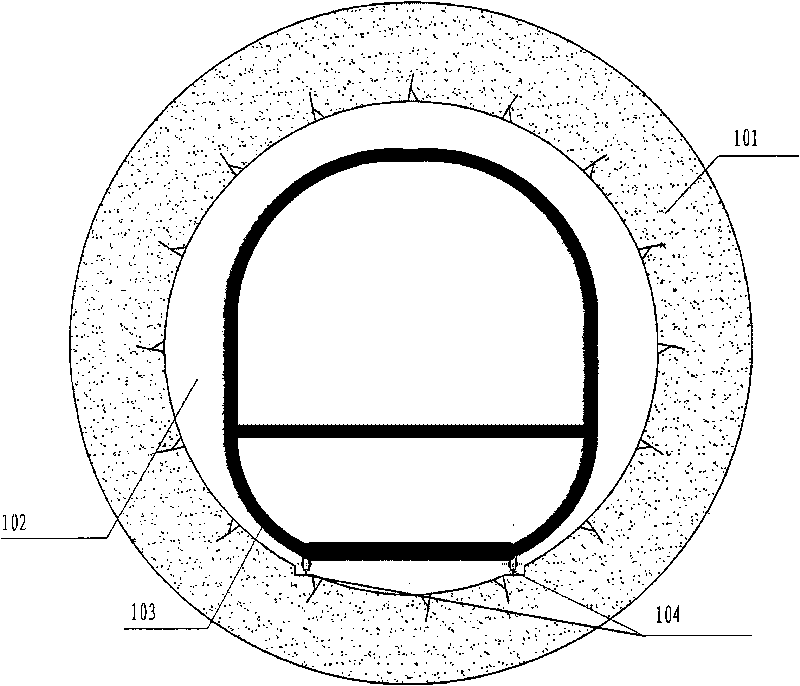

Embodiment 1

[0010] Embodiment 1: adopt figure 2 The pipeline structure shown is composed of a pipeline (101) and a hydrogen medium (105) at normal pressure. There are wheel-rail vehicles (103), wheel tracks (104), etc. in the pipeline (101), and the pipeline (101) is a sealed structure , to ensure that the outside air cannot enter the inside, the pipeline material can be leak-proof cement or steel plate, engineering plastics, etc., the ratio of the hydrogen medium (105) to the space volume in the pipeline is 80-100%, and the wheel-rail vehicles in the pipeline (101) (103) Operate under the environment of hydrogen medium (105), because the airflow resistance of hydrogen medium (105) to wheel-rail vehicle (103) is about 1 / 14 of the air resistance of the same pressure, so under the same pressure, the light gas pipeline The transportation speed in (101) can be increased, so as to obtain an economical running speed exceeding 1000km / h.

[0011] The characteristic of this scheme is that atmosp...

Embodiment 2

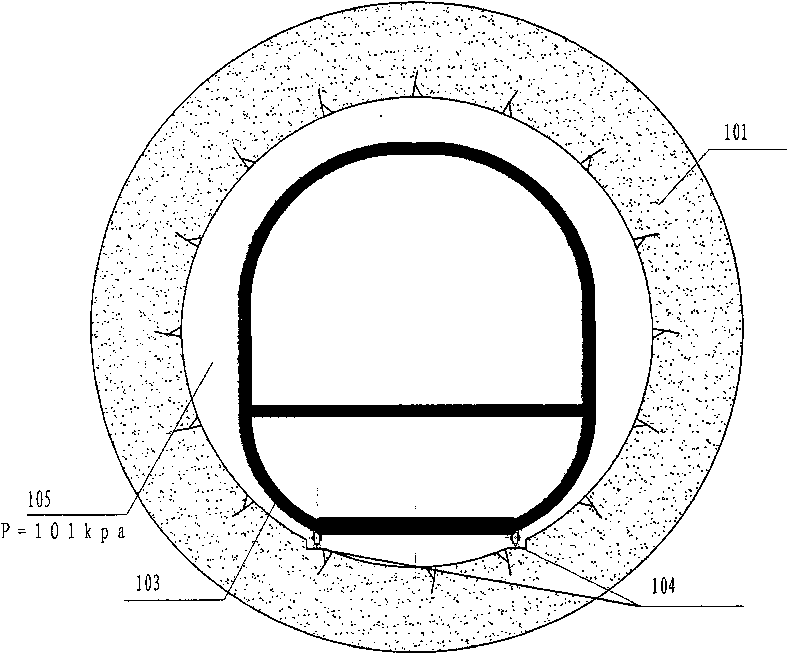

[0012] Embodiment 2: adopt image 3 The pipeline (101) structure shown is composed of pipeline (101) and helium gas (108) at normal pressure. There are magnetic levitation vehicles (106), guide rails (107), etc. in the pipeline (101), and the pipeline (101) is a sealed structure , to ensure that the outside air cannot enter the inside, the pipeline (101) can be made of leak-proof cement, or steel plate, engineering plastics, etc., and the magnetic levitation car body in the pipeline (101) runs under the helium environment, because the helium (108) The airflow resistance of the magnetic levitation vehicle (106) is about 1 / 7 of the air resistance at the same pressure, so under the same pressure, the transportation speed in the light gas pipeline (101) can be significantly increased, thereby obtaining an economical operating speed exceeding 600km / h.

[0013] The characteristic of this scheme is that normal-pressure helium is used as the intermediate medium, and the airflow resist...

Embodiment 3

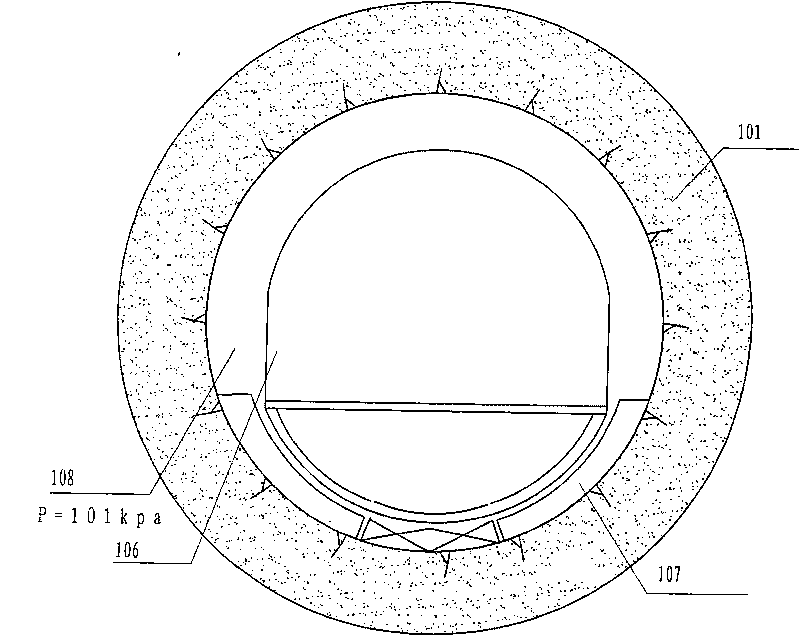

[0014] Embodiment 3: adopt Figure 4 The pipeline (101) structure shown is composed of pipeline (101), maglev vehicle (106), guide rail (107) and hydrogen medium (105) with a pressure of 10-20kPa. The pipeline (101) is a sealed structure to ensure External air cannot enter the interior, and the material of the pipe (101) can be leak-proof cement, or steel plate, engineering plastic, etc., and the ratio of the hydrogen medium (105) to the space volume in the pipe (101) is 80-100%, and the pipe (101) The maglev car body inside operates under the environment of low hydrogen gas medium (105), because the airflow resistance of the hydrogen gas medium (105) with a pressure of 10-20kPa to the transport vehicle is about 1 / 100 of the air resistance of an atmospheric pressure, so under the same pressure , the transportation speed in the light gas pipeline (101) can be greatly improved, thereby forming an ultra-high operating speed.

[0015] The characteristic of this scheme is that low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com