Engine structure of motor cycle

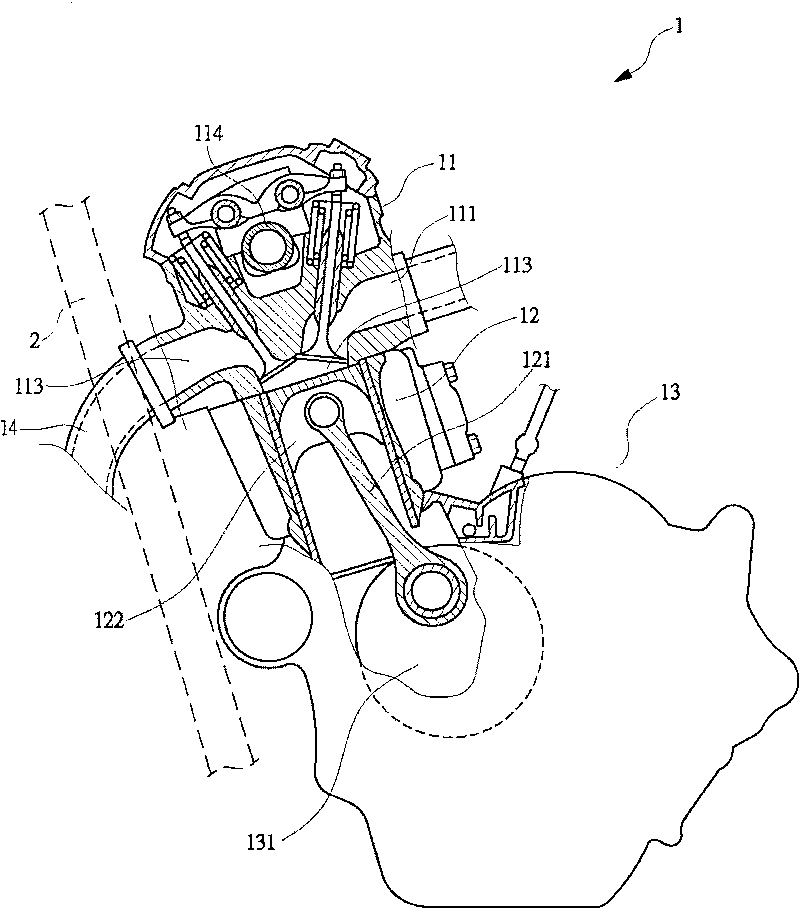

A motorcycle and engine technology, applied in the field of motorcycle engine structure, can solve the problems of inability to configure an O2 detector, a fuel tank or a water tank, and the difficulty of installing an exhaust pipe 14.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

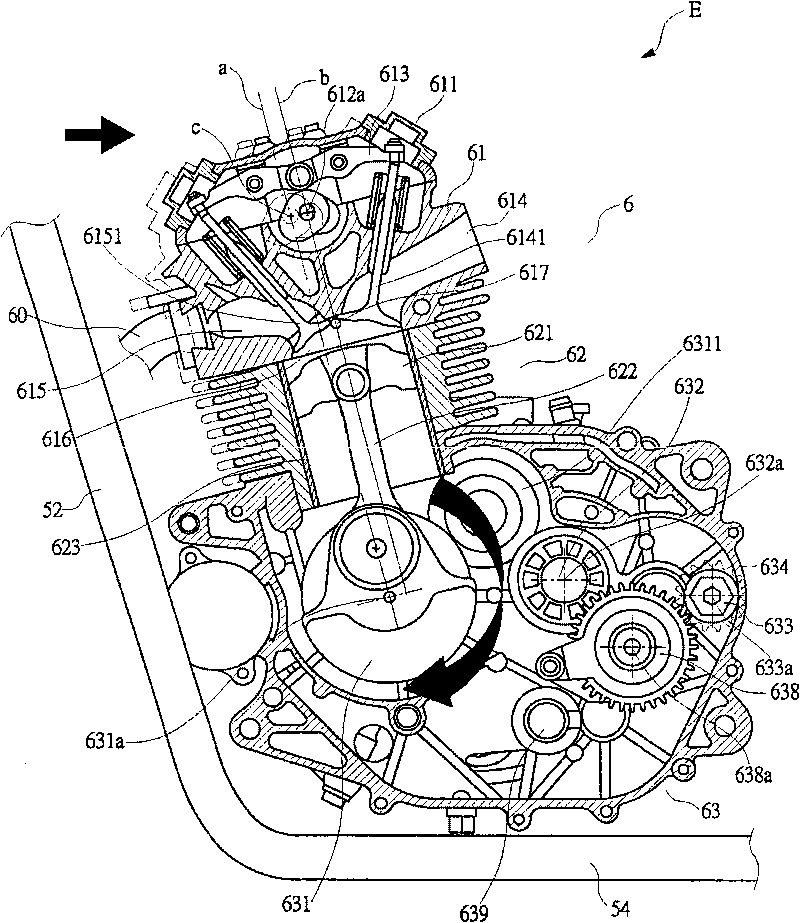

[0069] In order to make it easier to understand the structure of the present invention and the effect that can be achieved, it is described as follows in conjunction with the drawings:

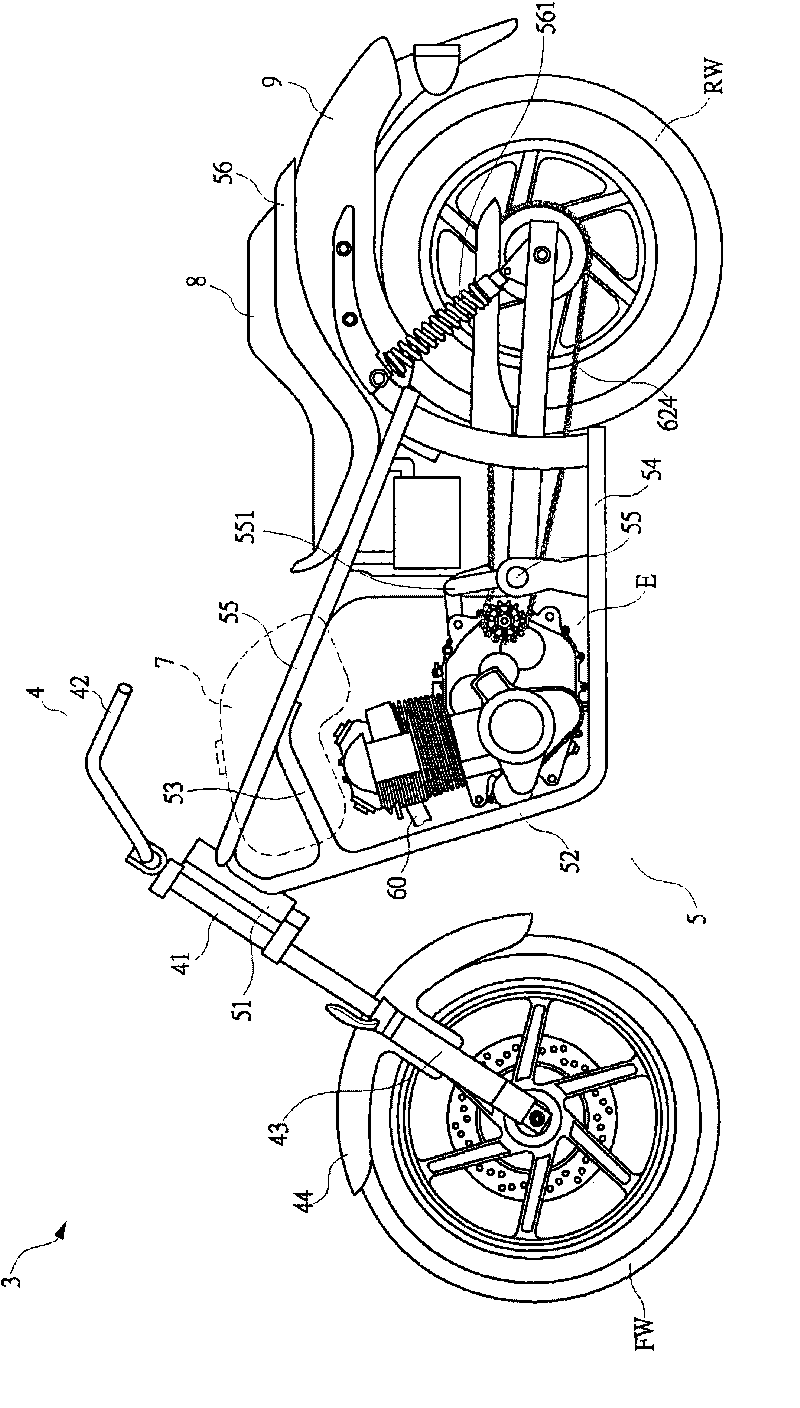

[0070] First, see figure 2 As shown, the motorcycle 3 of the present invention at least includes a steering mechanism 4, a frame unit 5, a power unit 6, a fuel tank 7, a driver's seat 8, and the like.

[0071] The steering mechanism 4 mainly includes a steering handle 42 above the steering head pipe 41, and a front shock absorber 43 is connected below the steering head pipe 41, and the bottom of the front shock absorber 43 is supported by a front wheel FW. , A front soil removal 44 is provided between the steering head pipe 41 and the front wheel FW.

[0072] The vehicle frame unit 5 has a main pipe 51 extending from the upper part of the steering head pipe 41 toward the rear and inclined downwards. In addition, a descending pipe portion 52 extends downwards in the middle of the steering hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com