Cast stone microcrystal plate

A technology of microcrystalline plate and cast stone, which is applied in the field of new wear-resistant and anti-corrosion materials, can solve the problem that the thickness of cast stone plate cannot meet the market demand, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

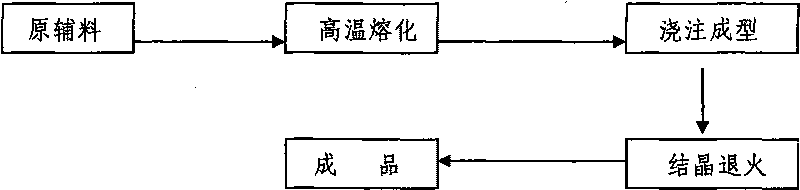

Method used

Image

Examples

Embodiment 1

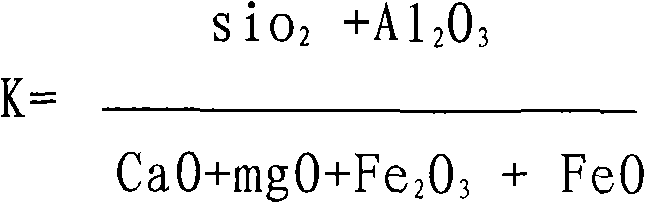

[0013] Embodiment 1: a kind of cast stone microcrystalline plate, its component and weight content are:

[0014] 44% of silicon dioxide, 15% of aluminum oxide, 8% of calcium oxide, 8% of oxidized metal, 16% of ferric oxide and ferrous oxide.

Embodiment 2

[0015] Embodiment 2: a kind of cast stone microcrystalline board, its component and weight content are:

[0016] Silicon dioxide 53%, aluminum oxide 20%, calcium oxide 18%, oxide beauty 6%, ferric oxide and ferrous oxide 9%.

Embodiment 3

[0017] Embodiment 3: a kind of cast stone microcrystalline board, its component and weight content are:

[0018] Silicon dioxide 49%, aluminum oxide 18%, calcium oxide 12%, oxide beauty 7%, ferric oxide and ferrous oxide 12%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com