High-temperature superconducting nanometer composite film and method for preparing same

A high-temperature superconducting thin film and nanocomposite technology, applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., can solve problems such as economical infeasibility, widen applications, and improve critical current density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

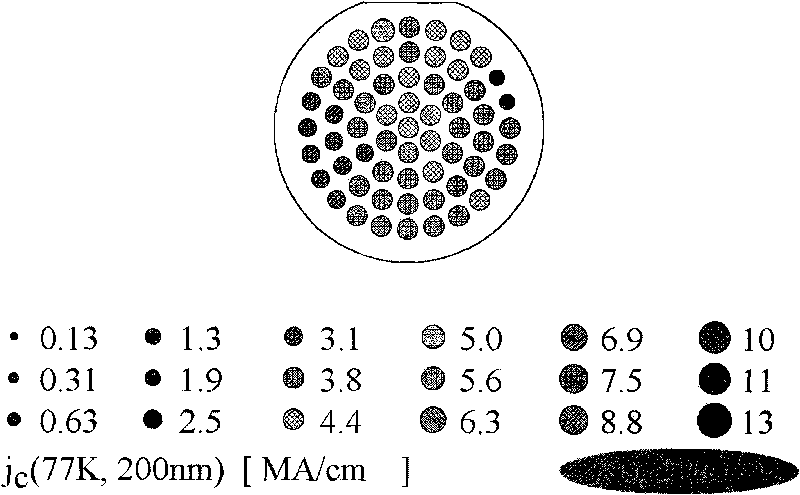

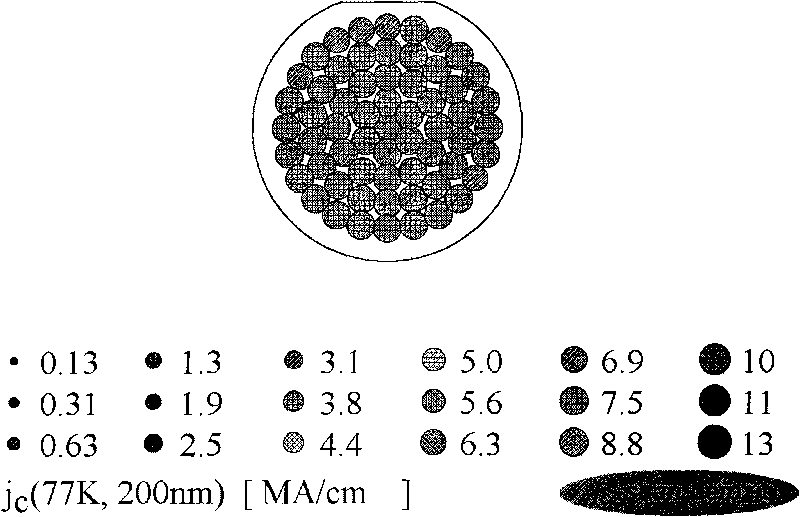

Image

Examples

Embodiment 1

[0023] Y(CH 3 COO) 3 , Ba(CH 3 COO) 2 and Cu(CH 3 COO) 2 Mix and dissolve at room temperature in deionized water containing an equivalent amount of trifluoroacetic acid to form a solution. The deionized aqueous solution contains 25 mol% of trifluoroacetic acid.

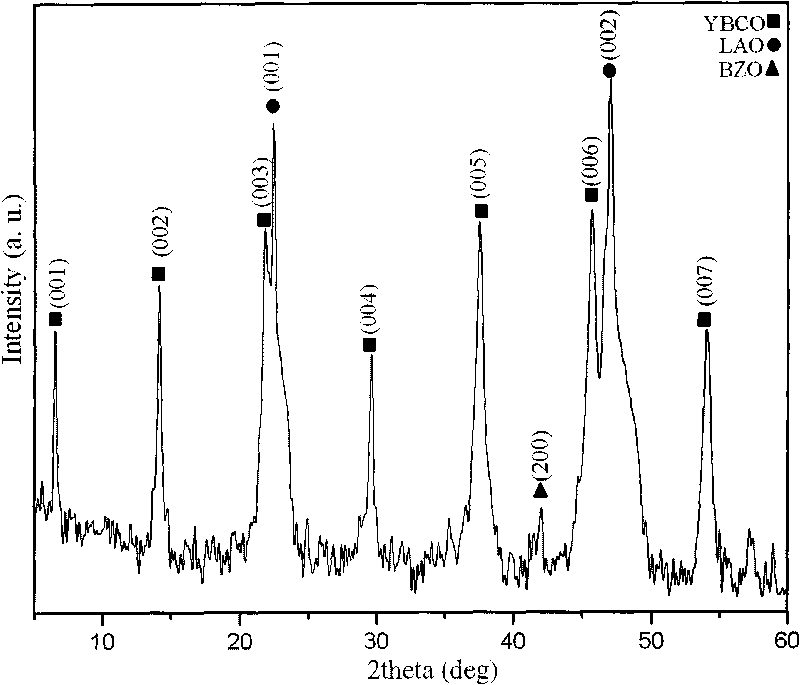

[0024] The prepared solution was stirred on a magnetic stirrer for 2 hours to improve the uniformity of the solution, and then the solution was vacuum-dried with a rotary evaporator to form a blue sol, and then methanol was added to completely dissolve the gel. After stirring, the solution was vacuum-dried again with a rotary evaporator It is a blue sol, and methanol and zirconium acetylacetonate are finally added therein to make a precursor solution whose total ion concentration of Y, Ba and Cu is 1.52mol / L, and the concentration of zirconium acetylacetonate is the total ion concentration of the three metals 8% mol.

[0025] The prepared precursor solution was spin-coated on LaAlO at 3000 rpm 3 on a single cry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com