Cement concrete curing agent and preparation method thereof

A technology for cement concrete and a manufacturing method, applied in the field of building material cement concrete curing agent, can solve the problems of high cost of resin-type curing agent, affecting the next process, wasting water resources, etc., so as to reduce the maintenance cost and labor intensity, and avoid waste. Water resources, the effect of saving engineering water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: Sodium silicate 10% urea 5% triethanolamine 2% sodium fluorosilicate 3%, the balance of water.

Embodiment 2

[0025] Example 2: Sodium silicate 15% urea 6% triethanolamine 1% sodium fluorosilicate 5%, water balance.

Embodiment 3

[0026] Embodiment 3: Sodium silicate 10% urea 2% triethanolamine 3% sodium fluorosilicate 0.2%, the balance of water.

[0027] The production method of the present invention is as follows: uniformly add sodium silicate, urea, triethanolamine and sodium fluorosilicate into water at 40°C-60°C, stir evenly, and prepare a curing agent with a density of 1.1-1.2g / ml.

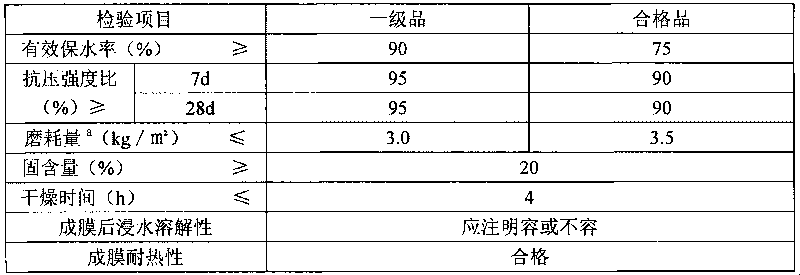

[0028] Main Specifications:

[0029] Technical requirements for surface film-forming curing agent

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com