Waste incineration method capable of inhibiting generation of dioxins and system thereof

A technology of waste incineration and waste incinerator, which is applied in the field of waste incineration for suppressing the generation of dioxin-like substances, can solve the problems of not completely covering the temperature range, high toxicity, and difficult to degrade, and achieves the elimination of dioxin-like substances pollution. , the effect of optimizing the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

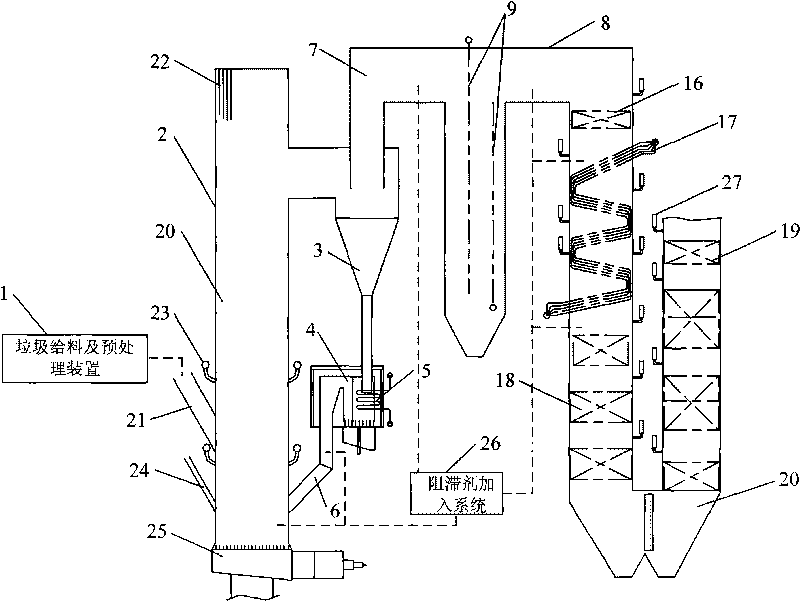

[0051] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

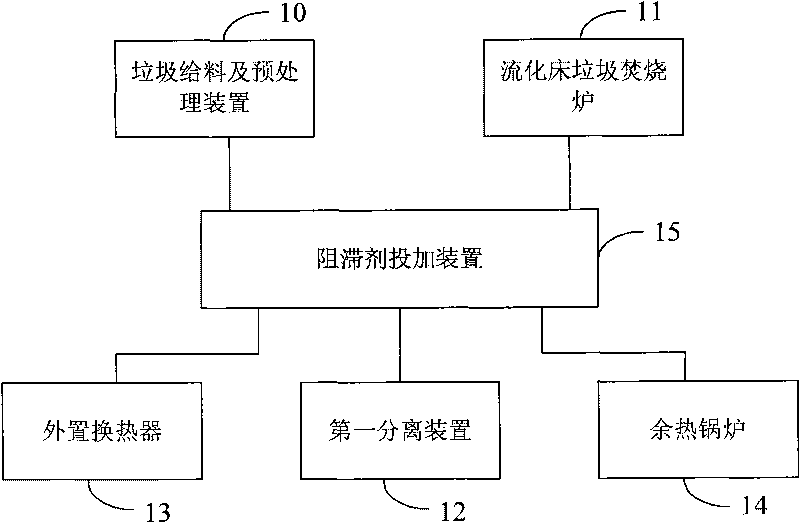

[0052] refer to figure 1 , shows a structural block diagram of an embodiment of a waste incineration system for inhibiting the generation of dioxins in the present invention, including: a fluidized bed waste incinerator 11, a first separation device 12, an external heat exchanger 13, and a waste heat boiler 14 , Blocking agent dosing device 15.

[0053] The fluidized bed waste incinerator 11, the first separation device 12 and the waste heat boiler 14 are connected in sequence.

[0054] Wherein, the first separation device 12 is located at the furnace outlet of the incinerator 11, and is connected to one end of the waste heat boiler 14 through a flue, and is used for separating high-temperature flue gas including fly ash generate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com