Preparation method of ultra-fine grain binding-phase-free hard alloy

A binder-free, cemented carbide technology, applied in the field of cemented carbide, can solve problems such as grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The invention provides a method for preparing ultrafine-grain cemented carbide without a binder phase, the preparation method comprising:

[0053] Weigh the raw material powder according to the composition ratio of ultra-fine-grained cemented carbide without binder phase, add carbon powder to the raw material powder to form a mixture, grind and mix the mixture in an inert atmosphere to obtain a mixed powder, and add carbon powder Quantity is C total ;

[0054] Molding the mixed powder to obtain a green body;

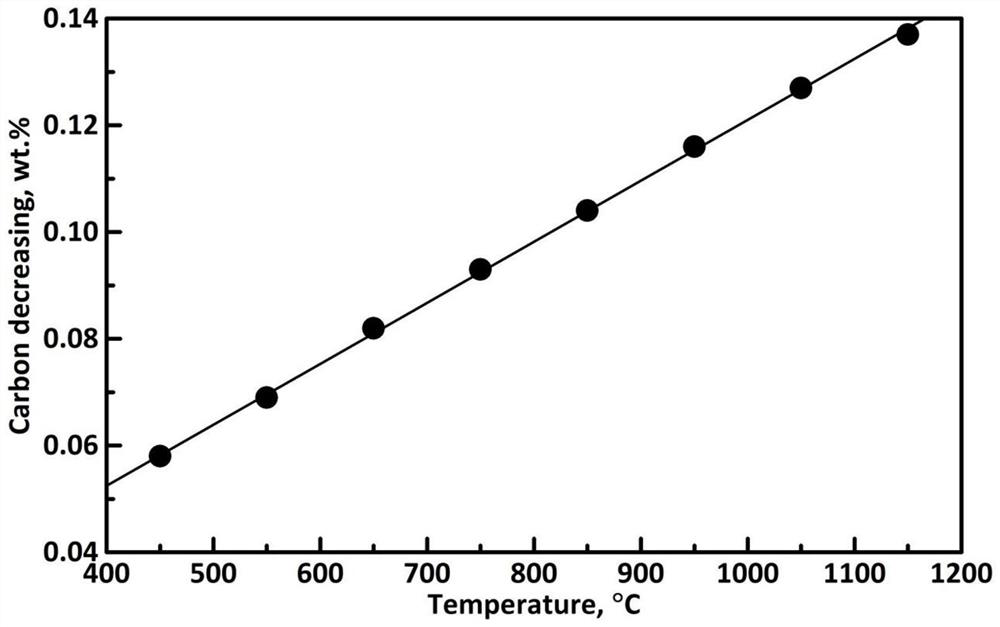

[0055] Carry out degreasing treatment and homogenization heat treatment on the green body;

[0056] Carry out oxidation treatment to the green body after homogenization heat treatment;

[0057] Carrying out sintering treatment on the green body after oxidation treatment to obtain ultra-fine grain cemented carbide without binder phase;

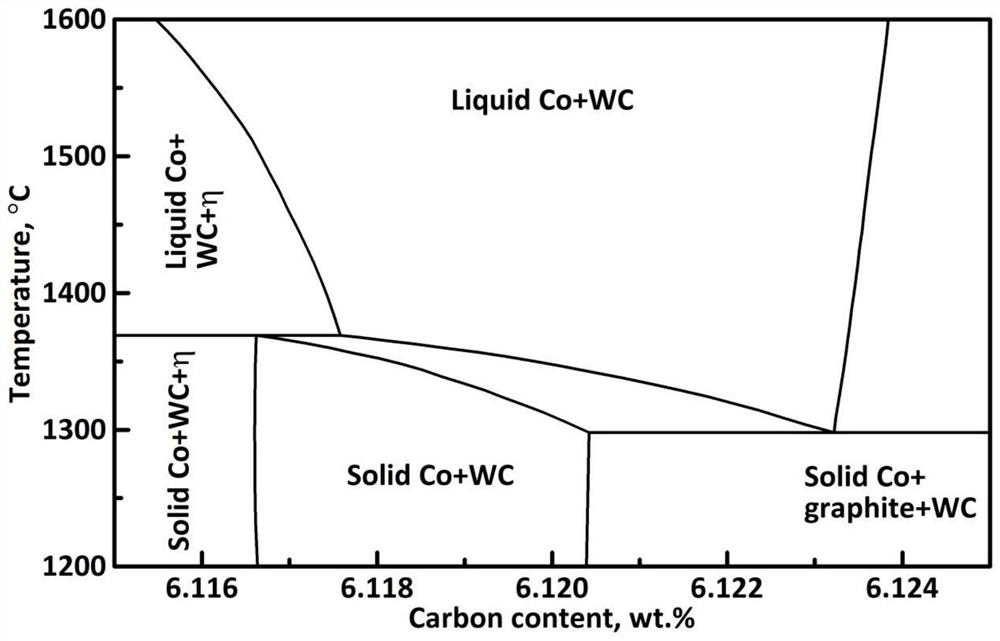

[0058] Among them, the amount of carbon powder added C total Calculated by formulas (1) and (2):

[0059] C total =C adju...

Embodiment 1

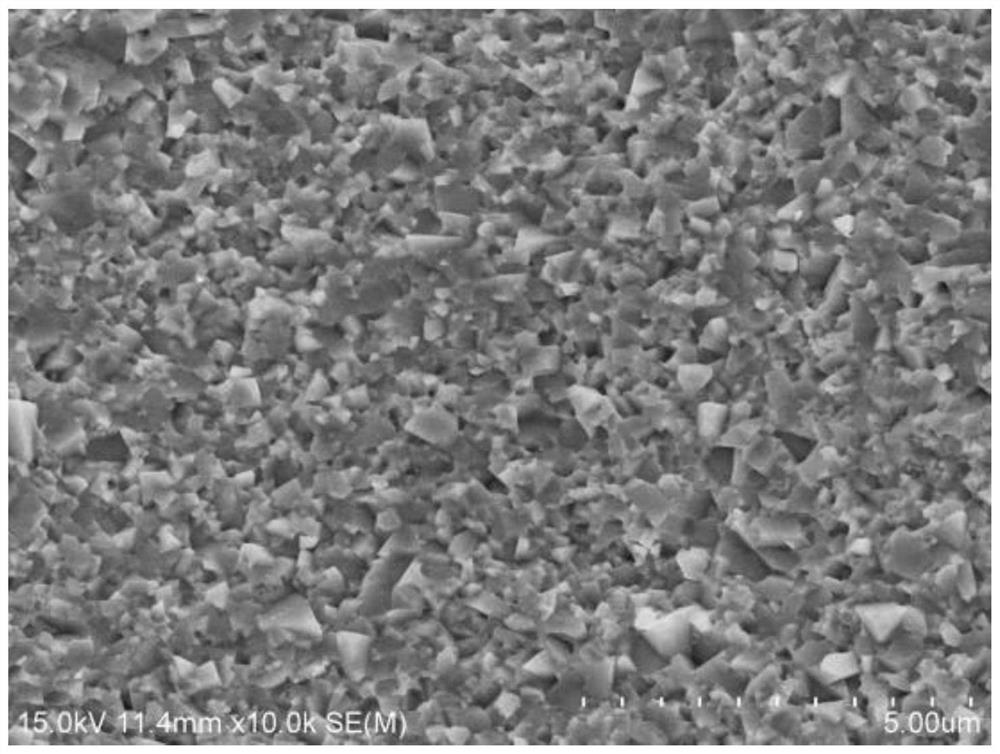

[0107] This example provides a method for preparing an ultra-fine grain cemented carbide without a binder phase. The composition of the ultrafine grain cemented carbide without a binder phase is shown in Table 1:

[0108] Table 1

[0109]

[0110] in,

[0111] The average particle size of WC powder is 0.1μm, and the theoretical carbon content is 6.1275wt.%.

[0112] The average particle size of Co powder is 0.4μm, and the theoretical carbon content is 0wt.%.

[0113] Cr 3 C 2 The average particle size of the powder is 0.72μm, and the theoretical carbon content is 13.3342wt.%.

[0114] The average particle size of VC powder is 0.8μm, and the theoretical carbon content is 19.0654wt.%.

[0115] According to formula (3), it can be known that the theoretical carbon content C of the alloy theory-total = 6.1901 wt.%.

[0116] This preparation method comprises the steps:

[0117] 1) Determination of the carbon content and oxygen content of the raw material powder, among whi...

Embodiment 2

[0141] The composition and raw material powder of the superfine-grain cemented carbide without binder phase of the present embodiment are the same as that of the embodiment 1, and ΔC is 0.08wt.% in the present embodiment, and the amount of carbon black added is C total It is 0.2978wt.%.

[0142]Accurately weigh each raw material powder and carbon black powder. The average particle size of the carbon black powder is 0.02 μm. In an inert atmosphere, place the raw material powder and carbon black powder in a ball mill, using cemented carbide balls and high Pure absolute ethanol is carried out ball milling, and ball milling time is 54h, and wherein, the mass ratio of cemented carbide ball and raw material powder and carbon black powder is 4:1;

[0143] The molding process is adopted in the first pressing stage, and the pressing pressure is controlled at 0.4t / cm 2 , to obtain a low-density green body, and then adopt cold isostatic pressing in the second pressing stage with a press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com