Hyperboloid balance flow gauge

A flowmeter and hyperboloid technology, applied in the field of machinery, can solve the problems of increasing maintenance, changing the cross-sectional area of the pipeline, measuring disorder, etc., to achieve accurate and more effective measurement data, improve measurement accuracy, and reduce momentum loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

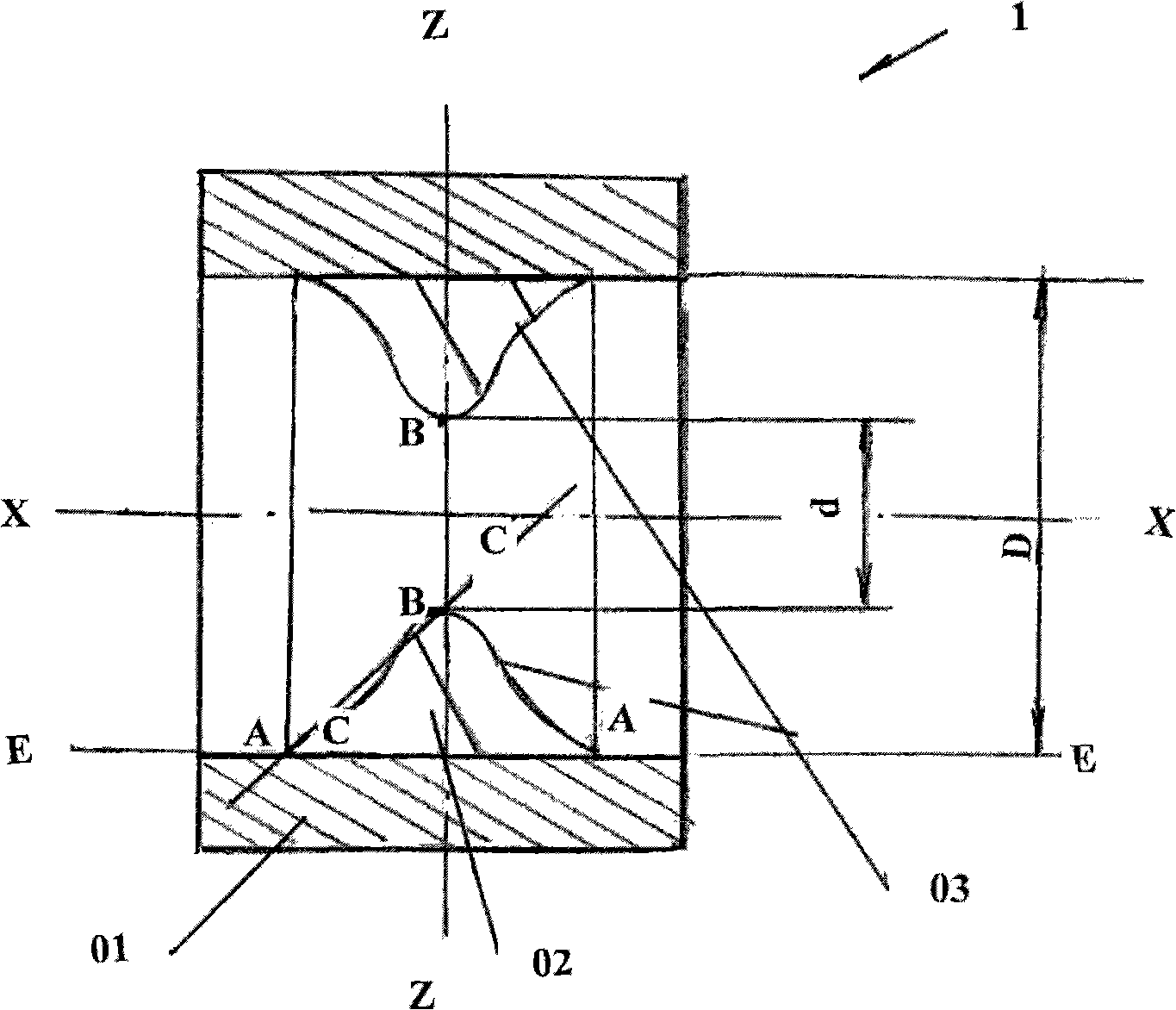

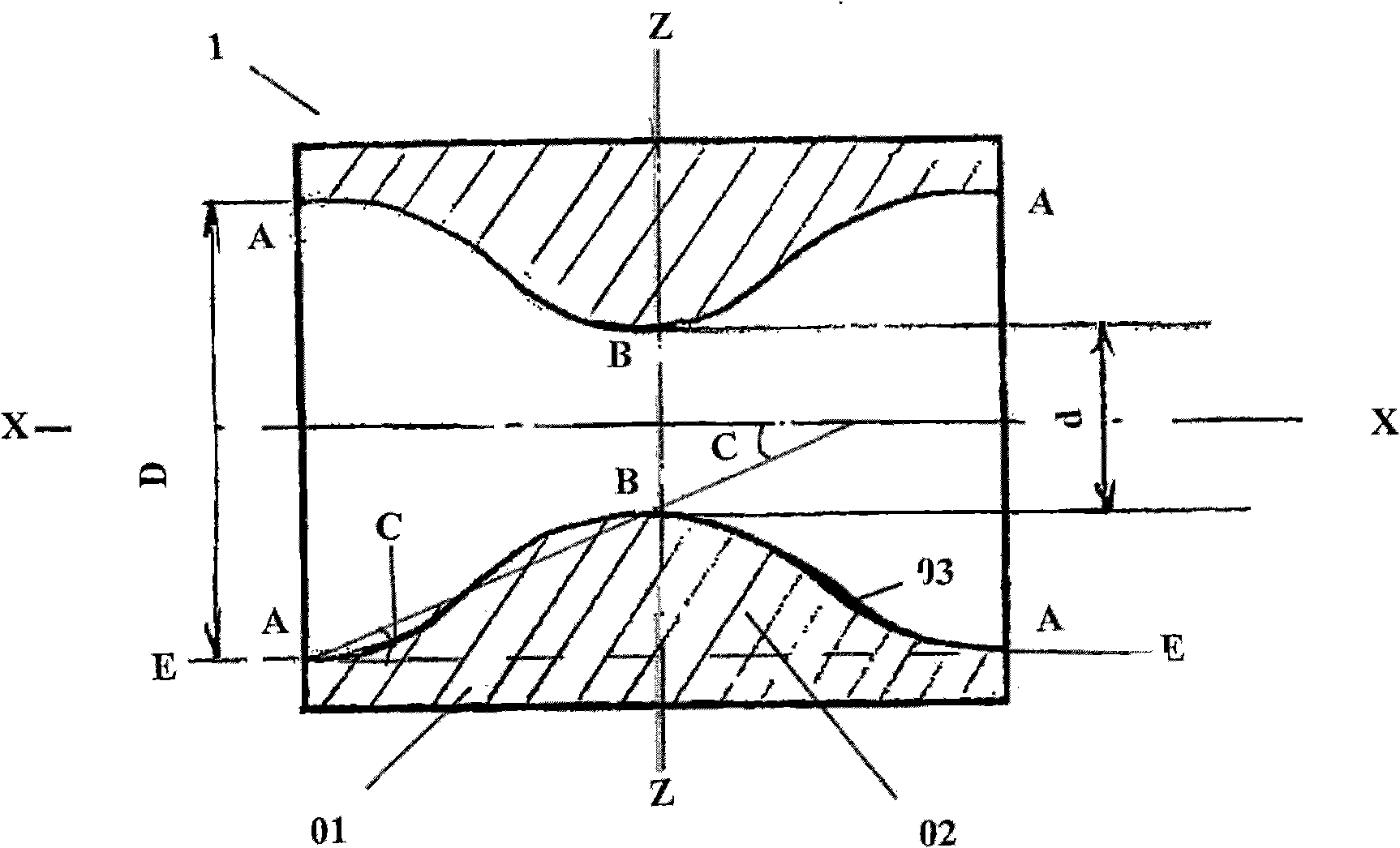

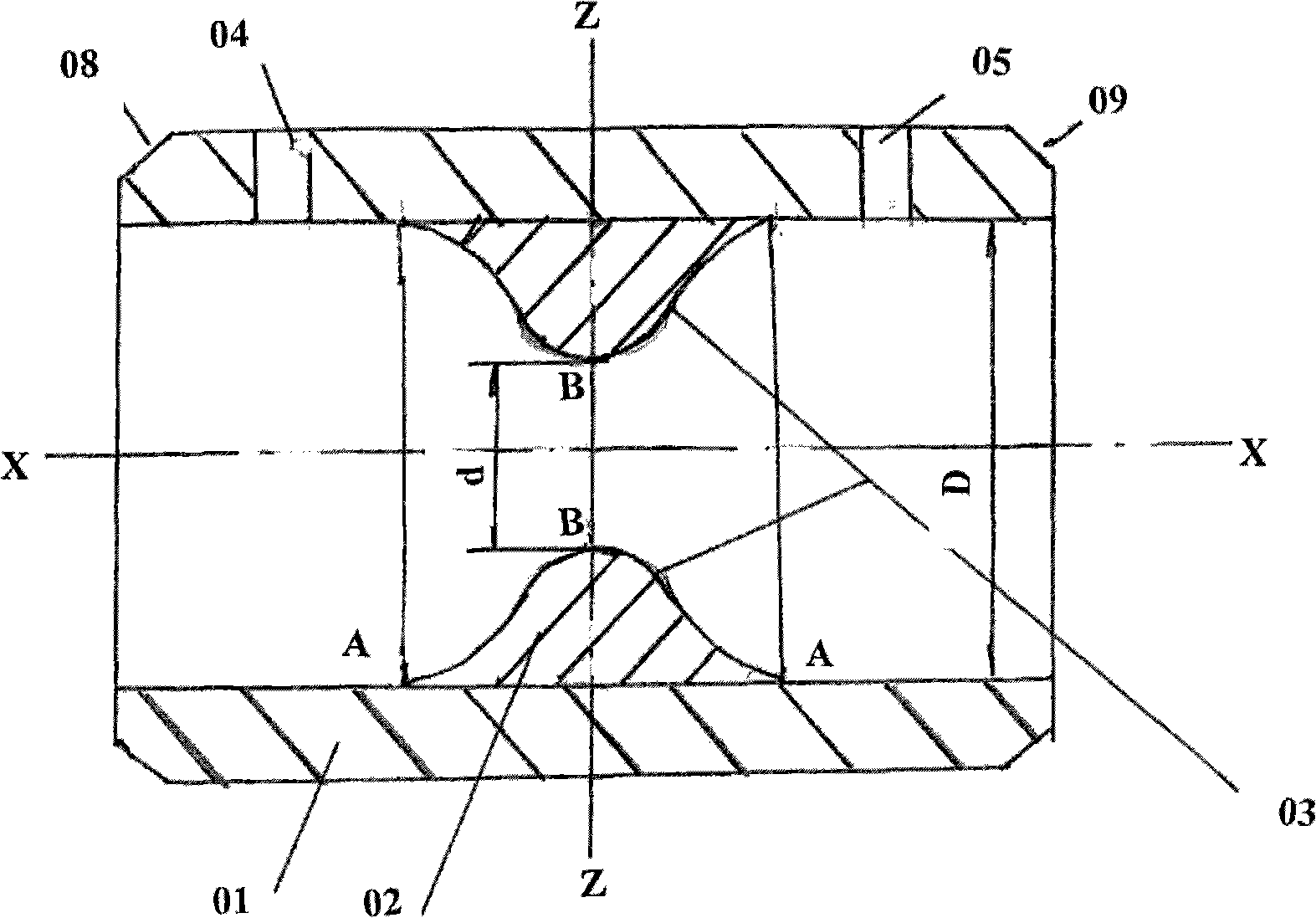

[0024] The flowmeter of the present invention can be called a hyperboloid balanced flowmeter according to the structure, and the flowmeter is installed in the channel through which the fluid passes so as to cross the pipeline, or installed in two flanges connecting two adjacent pipelines , communicate with the pipeline through the hole in the flange.

[0025] The structural features of the flowmeter of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0026] The structure of the flowmeter of the present invention belongs to the differential pressure orifice flowmeter, and the structure of the differential pressure orifice flowmeter is well known to those skilled in the art. Therefore, only the structure of the flowmeter of the present invention-a longitudinal sectional view is provided here , to be explained.

[0027] refer to figure 1 , figure 1 It is an explanatory view of the structure of the flowmeter of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com