Novel low-cost high-density sodium-nickel chloride single battery and battery pack thereof

A single battery, low-cost technology, applied in the direction of battery electrodes, battery pack components, secondary batteries, etc., can solve the problems of complexity and limited application, and achieve the effects of long service life, convenient manufacture, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

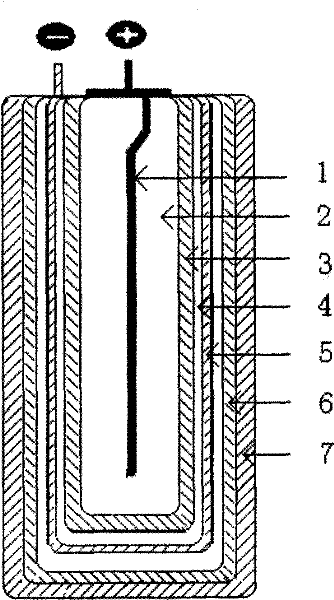

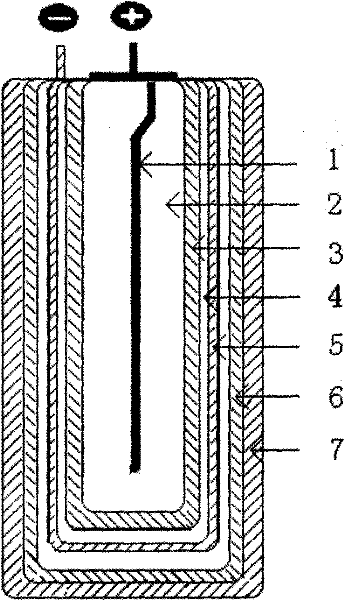

[0029] like figure 1 A novel low-cost high-density sodium-nickel chloride single battery of the present invention is shown, comprising a positive electrode of a porous nickel material, a filled molten salt electrolyte, a solid electrolyte ceramic tube (length 220mm, internal diameter 52mm, wall thickness 2mm) , Na in the metal sheet is the negative active material, the shell (60*60*245mm) and the heat insulating layer material wrapped outside the shell, the battery is in turn from the outside to the inside of the heat insulating layer material, the shell, the metal sheet, and the metal sheet The Na in the negative electrode active material, the solid electrolyte ceramic tube, the filled molten salt electrolyte and the positive electrode of the porous nickel material, the Na of the negative active material and the filled molten salt electrolyte are respectively filled on both sides of the solid electrolyte, and the metal sheet is coated on the On the solid electrolyte ceramic t...

Embodiment 2

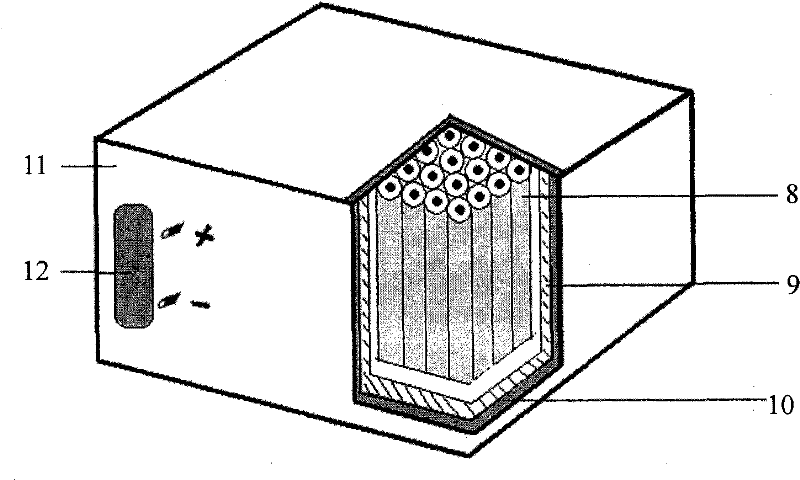

[0031] like figure 2Shown, the novel low-cost high-density sodium-nickel chloride battery pack of the present invention, it comprises the monomer battery as described in embodiment 1 that is connected in parallel together, also comprises cooling device, battery pack insulation layer, battery pack case simultaneously And the whole battery control system, wherein the number of single cells is 30, and the appearance of the battery pack is rectangular; the heat insulation layer of the battery pack is a silica airgel heat insulation layer or a ceramic felt heat insulation layer or a glass fiber heat insulation layer layer; the cooling device has a fan; the battery pack casing is made of low-carbon steel; the internal working temperature of the battery pack is between 270°C and 350°C and is regulated by the battery controller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com