Preparation method of spicy soy sauce

A production method and technology of soy sauce, which are applied in the field of soy sauce, can solve the problems of not using chili flavor enhancers, lack of product flavor, complex production process, etc., and achieve the effects of low production cost, increased appetite, and full utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

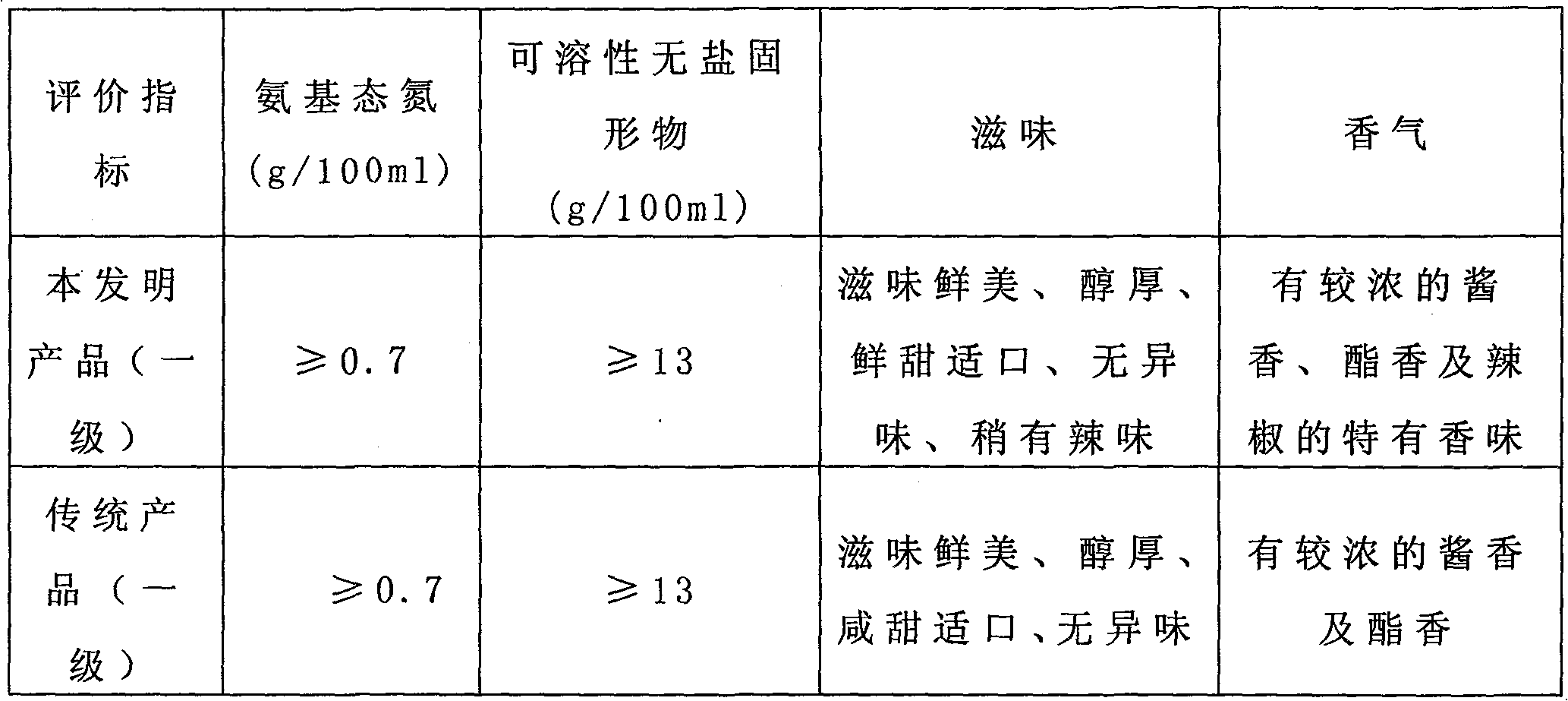

Image

Examples

Embodiment 1

[0020] Raw materials: soybeans, flour, bran, salted pepper base filtrate, Aspergillus oryzae strains (Shanghai Brewed 3.042)

[0021] Excipients: potassium sorbate 0.5g / kg, sodium benzoate 0.5g / kg, sucralose 0.2g / kg

[0022] According to the operation process of the high-salt dilute state fermentation process, take 600g soybeans and 270g flour to make 1400g koji, use the salted chili base filtrate with a salt mass concentration of 20% to wet the koji, and then add 3000ml of salt The filtrate of the salted chili base with a mass concentration of 20% is made into soy sauce, and fermented in the open air for 3 to 6 months. After the soy sauce is mature, the head oil is released, and then 1500ml of salted pepper with a mass concentration of 20% is added. Soak the filtrate of pepper blanks for 10 days, release the second filter oil, add 1500ml of salted pepper blank filtrate to soak the second filter residue, release the third filter oil, blend according to the requirements of diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com