Preparation method of magnetic sulfur-containing bidentate palladium ligand catalyst

A bidentate ligand and catalyst technology, applied in the field of catalyst preparation, can solve problems such as difficulty in recovering a homogeneous palladium ligand catalyst, and achieve the effects of strong practicability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

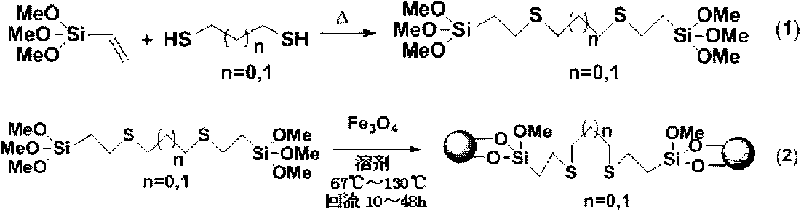

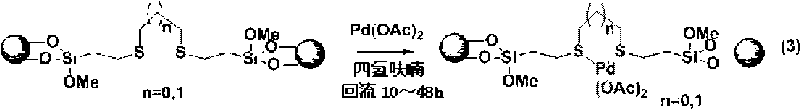

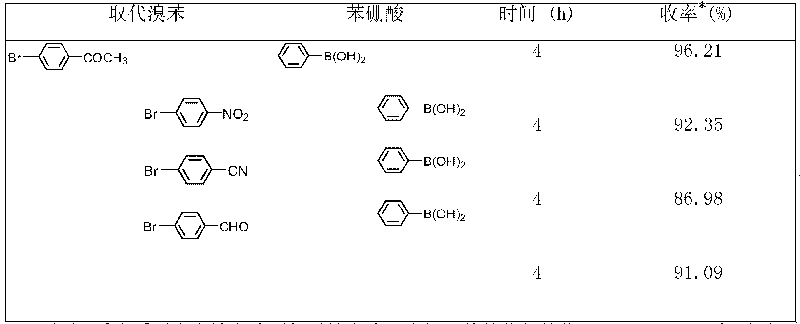

[0007] Embodiment 1: The preparation method of the magnetic sulfur-containing bidentate palladium ligand catalyst in this embodiment is as follows: 1. Preparation of sulfur-containing bidentate ligands containing active groups: coupling sulfur-containing bidentate ligands with silane The agent is mixed according to the molar ratio of 1:1~5, stirred and heated to 40°C~110°C, then kept at 40°C~110°C for 1 hour to 8 hours, and then rotary steamed (purpose to remove excess silane coupling agent ), promptly get the sulfur-containing bidentate ligand (reaction formula as shown in (1)) containing active group; Two, Fe 3 o 4 Preparation of immobilized sulfur-containing bidentate ligands: Under the condition of inert gas protection, the sulfur-containing bidentate ligands containing active groups and superparamagnetic Fe 3 o 4 The nanoparticles are added to the solvent in turn, then ultrasonically oscillated for 20 minutes, then stirred at a temperature of 67°C to 130°C, and refluxed...

specific Embodiment approach 2

[0010] Embodiment 2: This embodiment differs from Embodiment 1 in that the sulfur-containing bidentate ligand in step 1 is 1,2-dimercaptoethane or 1,3-dimercaptopropane. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the silane coupling agent described in step one is vinyltrimethoxysilane, 3-chloropropyltrimethoxysilane, 3-chloropropyl Triethoxysilane, 3-bromopropyltrimethoxysilane or 3-(2,3-glycidoxy)propyltrimethoxysilane. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com