Method for reducing self-excited vibration of deep-hole processing boring bar and power vibration damping boring bar thereof

A technology of self-excited vibration and dynamic vibration reduction, applied in the direction of boring bars, etc., can solve the problems of verification, no design of boring bars, processing, etc., and achieve the effect of improving quality, simple structure, and suppressing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

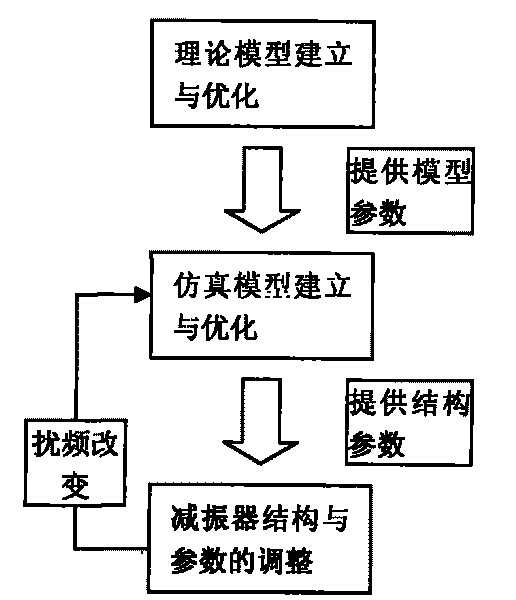

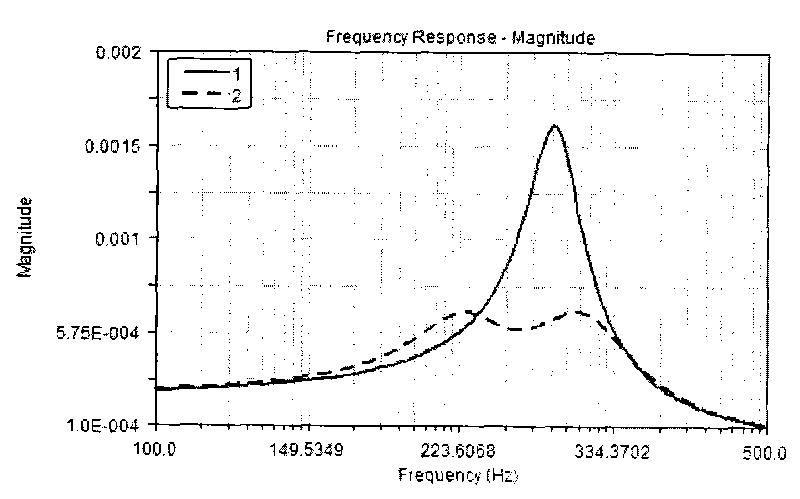

[0021] refer to figure 1 , figure 2 . According to the present invention, a theoretical model of the dynamic damping boring bar is established and optimized to obtain optimized initial values and preliminary structural design values. Then the simulation model is built on the basis of the theoretical model and optimized. Finally, the boring bar is designed according to the optimization calculation results, and the shock absorber parameters are selected. If it is necessary to modify the shock absorber parameters of the dynamic damping boring tool, the optimization calculation can be performed again through the simulation model to obtain new shock absorber parameters and adjust the dynamic shock absorber.

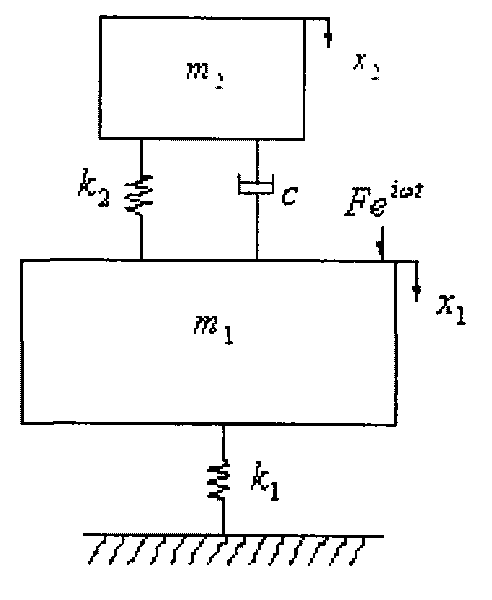

[0022] 1) In the theoretical model, the dynamic shock absorber can be simplified into a two-degree-of-freedom vibration system. Depend on figure 2 The mechanics model shown is set to the damping model. Among them, m2 is the mass of the damping rod, k2 is the ideal el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com