Method for strengthening sludge reduction of aerobic-sedimentation-anoxic process

A sludge reduction and process technology, applied in aerobic and anaerobic process treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of large power consumption and high cost, and achieve gas consumption less, low operating cost, and increased sludge reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

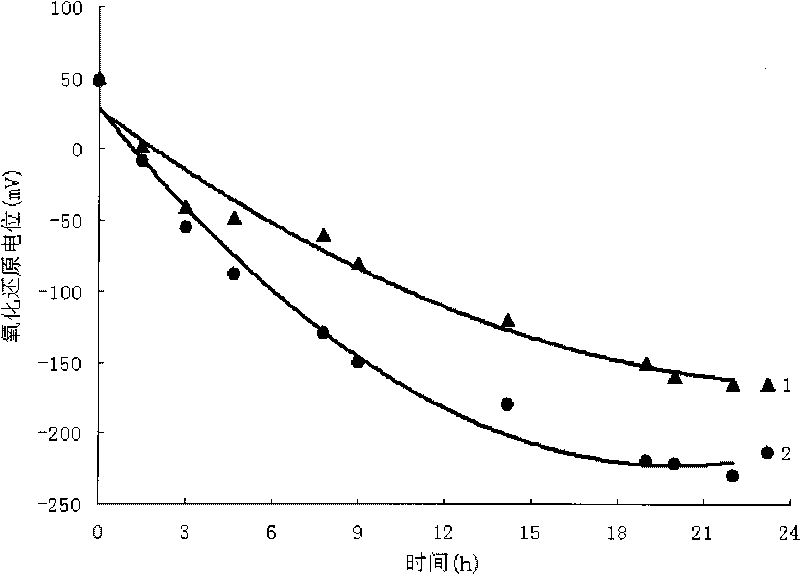

[0045] In this example, whether the aeration operation of the present invention is carried out in the anoxic tank in the traditional OSA process is tested, and the influence on sludge reduction is tested.

[0046] The sludge is taken from the anoxic stage sludge in the normal operation of the traditional OSA process at 50 tons / day, and is divided into 2 groups:

[0047] One group is without aeration control, as the control group;

[0048] Another group adopts the aeration control of the present invention as an experimental group.

[0049]Both groups were sealed in Erlenmeyer flasks. The experimental group was aerated for 30s every 1.5h, and the control group was left without any operation. Then the ORP value and suspended matter concentration (MLSS) of the two groups were measured to determine the amount of sludge reduction. Enhanced effect.

[0050] from image 3 It can be seen from the figure that the initial ORP values of the two groups of sludge were both +50mV, and a...

Embodiment 2

[0052] In this embodiment, the change of dissolved oxygen (DO) in sludge with time before and after the application of the aeration control technology of the present invention is studied.

[0053] This example is divided into two groups,

[0054] One group is the traditional OSA process, that is, the anoxic tank does not undergo aeration treatment, as the control group;

[0055] The other group is to perform the aeration operation of the present invention on the anoxic tank in the traditional OSA process. As an experimental group, the experimental group performs aeration every 1.5 hours, and each aeration is about 30s. The experiment continued for about 22 hours.

[0056] Table 1 has provided in the control group and the experimental group, the DO of the sludge in the anoxic pond changes with time, as can be seen from Table 1, because each aeration time is shorter, so adopt the aeration control of the present invention It will not increase the concentration of dissolved oxyg...

Embodiment 3

[0060] This example is divided into two groups,

[0061] One group is the traditional OSA process, that is, the anoxic tank does not undergo aeration treatment, as the control group;

[0062] The other group is to perform the aeration operation of the present invention on the anoxic tank in the traditional OSA process, as an experimental group.

[0063] The initial conditions of this embodiment are: the mixed liquor suspended solids concentration (MLSS) of the sludge in the anoxic tank is about 12 g / L, and the mixed liquor volatile suspended solids concentration (MLVSS) is about 6 g / L.

[0064] Table 2 provides the comparison result of sludge reduction before and after the application of aeration control of the present invention, as can be seen from table 2, adopting aeration control to the anoxic tank has improved the self-decomposition rate of sludge, the concentration of MLSS and MLVSS The concentration of the sludge was lower than the results of anoxic sludge treatment in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com