Method for utilizing naphtha

A technology for naphtha and n-paraffins, which is applied in the fields of catalytic reforming of naphtha, hydrocarbon cracking, organic chemistry, etc., and can solve problems such as low yield of ethylene propylene, low conversion rate of desorbed oil, and high energy consumption , achieve the effect of low reaction temperature, lower benzene content and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

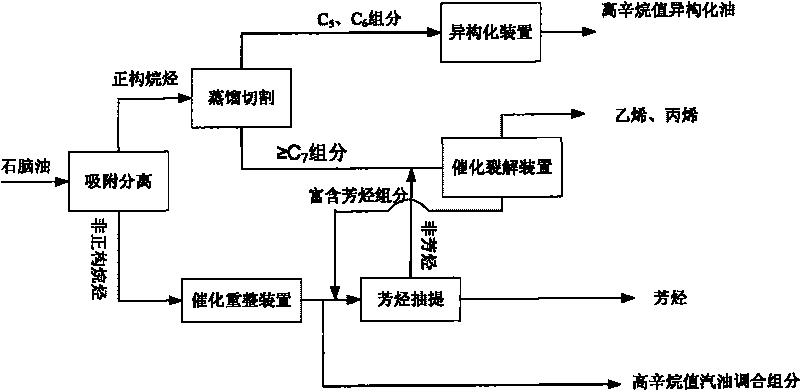

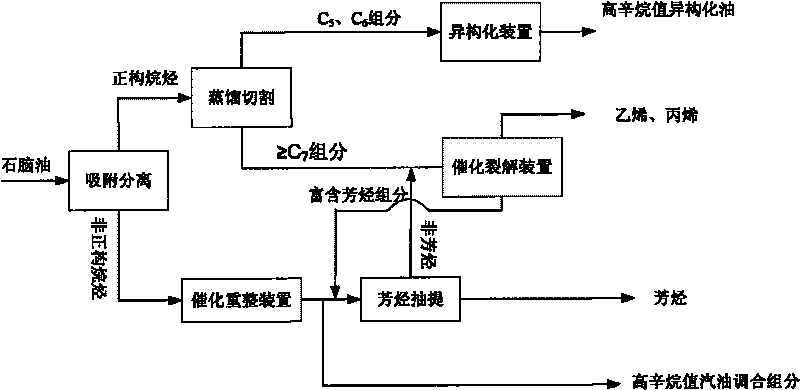

[0047] Such as figure 1 As shown, the density is 0.7076g / cm 3 , a distillation range of 35 to 153°C, a normal paraffin content of 28.34% by weight, an isoparaffin content of 30.31% by weight, a naphthene of 32.52% by weight, and an aromatic content of 8.79% by weight through a 5A molecular sieve adsorbent, The operating conditions are pressure 1.0MPa, 170°C, volumetric space velocity 0.8h -1 . The components flowing out of the 5A molecular sieve were condensed to obtain a component rich in non-normal paraffins with a yield of 69.26%, and the content of normal paraffins in the components rich in non-normal paraffins was 0.32%. After the adsorption process is over, use nitrogen to purge the bed for desorption. The nitrogen temperature is 170°C and the volume space velocity is 0.8h -1 , the purged component was condensed to obtain a component rich in n-alkanes, with a yield of 30.74%, and the content of n-alkanes in it was 96.68%.

[0048] The n-paraffin-rich component is cut...

Embodiment 2

[0063] Such as figure 1 As shown, the density is 0.7374g / cm 3 , a distillation range of 42 to 169°C, a normal paraffin content of 19.40% by weight, an isoparaffin content of 28.70% by weight, a naphthene of 38.28% by weight, and an aromatic content of 13.54% by weight. After pretreatment, the naphtha passed 5A Molecular sieve adsorbent, the operating conditions are pressure 2.5MPa, 230°C, volume space velocity 3.5h -1 . The components flowing out of the 5A molecular sieve were condensed to obtain a component rich in non-normal paraffins with a yield of 78.60%, and the content of normal paraffins in the components rich in non-normal paraffins was 0.18%. After the adsorption process is completed, the bed is purged with nitrogen for desorption. The nitrogen temperature is 230°C and the volume space velocity is 3.5h. -1 , the purged component was condensed to obtain a component rich in n-alkanes, with a yield of 21.40%, and the content of n-alkanes in it was 97.30%.

[0064] T...

Embodiment 3

[0078] Such as figure 1 As shown, the density is 0.6944g / cm 3 , a distillation range of 33 to 174°C, a normal paraffin content of 32.97% by weight, an isoparaffin content of 32.27% by weight, a naphthene of 27.08% by weight, and an aromatic content of 7.58% by weight. After pretreatment, the naphtha passed 5A Molecular sieve adsorbent, the operating conditions are pressure 0.5MPa, 200°C, volume space velocity 2.5h -1. The components flowing out of the 5A molecular sieve were condensed to obtain a component rich in non-normal paraffins with a yield of 65.11%, and the content of normal paraffins in the components rich in non-normal paraffins was 0.35%. After the adsorption process is completed, the bed is purged with nitrogen for desorption. The nitrogen temperature is 200°C and the volume space velocity is 2.5h. -1 , The purged component was condensed to obtain a component rich in n-alkanes, with a yield of 34.89%, and the content of n-alkanes in it was 96.80%.

[0079] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com