Mixed pulp and paper with the same

A technology of mixing pulp and straw pulp, which is applied in the field of pulp and papermaking, can solve the problems of single paper, can not comprehensively improve paper performance, low opacity, etc., and achieve the effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0151] 1. Preparation of unbleached straw pulp

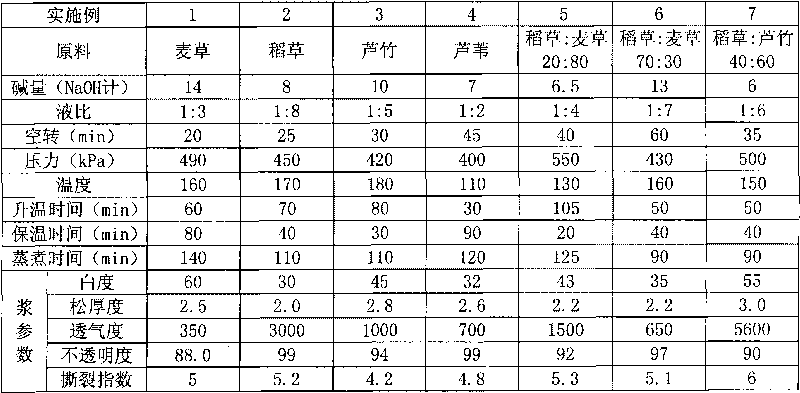

[0152] 1. Examples 1-7 are for the preparation of unbleached straw pulp by the caustic soda method, wherein the properties of the unbleached straw pulp are measured by conventional methods for the pulp obtained after cooking and washing.

[0153] Table 1. Parameters of caustic soda pulping

[0154]

[0155] The unit of bulk thickness in the table is cm 3 / g, air permeability unit ml / min, breaking length unit Km, folding endurance unit N.m / g, tear degree unit mN, tear index unit mN.m 2 / g. The table below is the same.

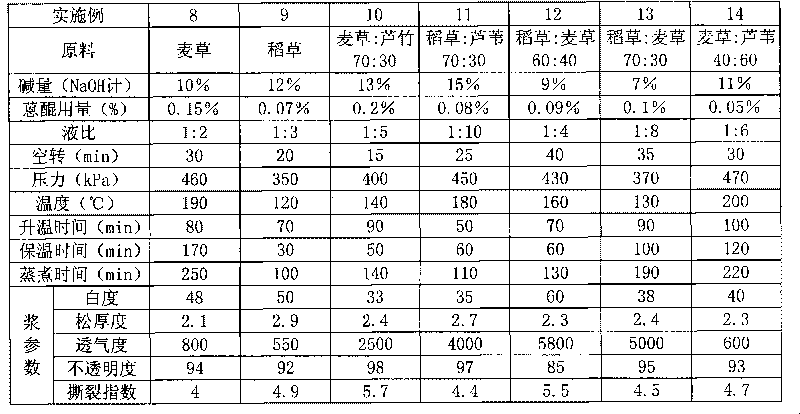

[0156] 2. In Examples 8-14, the caustic soda-AQ method was used to prepare unbleached straw pulp, wherein the properties of the unbleached straw pulp were measured by conventional methods on the pulp obtained after cooking and washing.

[0157] Table 2, pulping parameters of caustic soda-AQ method

[0158]

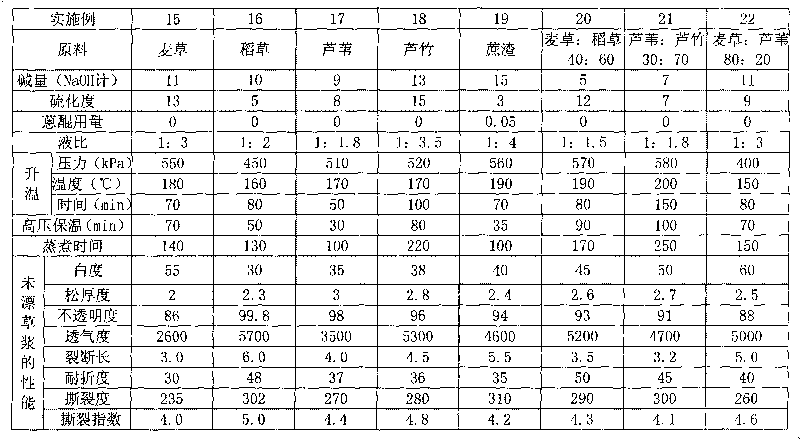

[0159] 3. In Examples 15-22, unbleached straw pulp was prepared by kraft method, wherein the pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| opacity | aaaaa | aaaaa |

| opacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com