Single spiral air-duct-type biomass boiler

A technology of spiral wind and biomass, which is applied in the direction of combustion method, block/powder supply/distribution, solid fuel combustion, etc., can solve the problem of increasing the process links of biomass crushing-mixing-forming-drying and unfavorable promotion Application, high boiler manufacturing costs and other issues, to achieve the effect of solving energy shortage and environmental pollution, great potential for popularization and application, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

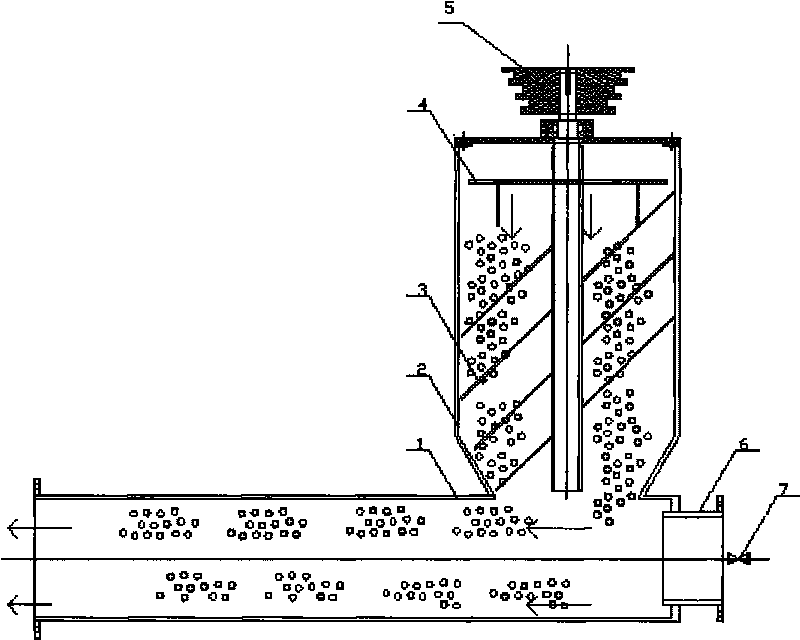

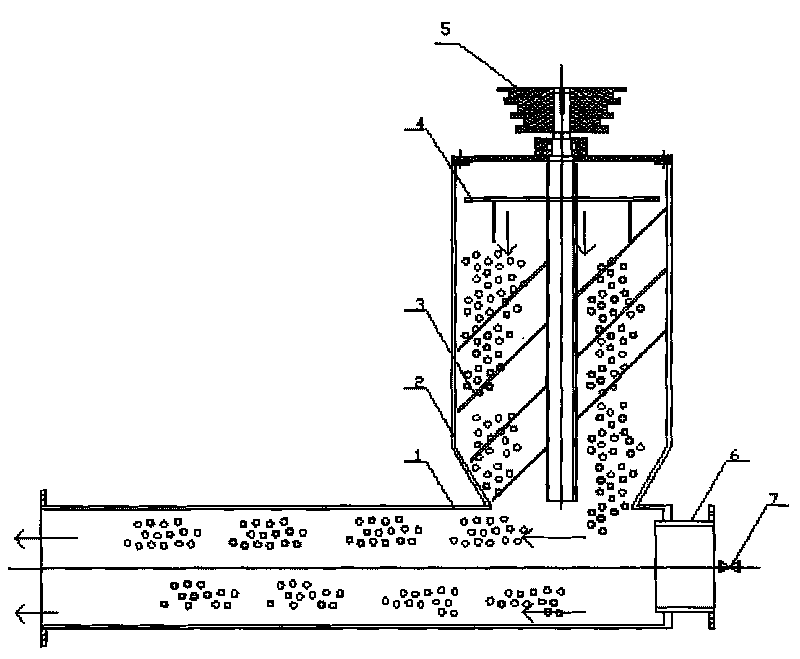

[0017] Such as figure 1 As shown, the biomass single-spiral air cylinder boiler includes a furnace body, a combustion chamber, and a fuel conveyor. The front end of the fuel cylinder 1 is connected to the boiler combustion chamber, and the end of the fuel cylinder 1 is connected to the fan through the fan interface 6. 7 is located at the fan interface 6, and the fuel bucket 2 is provided with a screw propulsion device. The screw propulsion device 3 is composed of a screw rod and blades installed on it. The upper end of the screw rod is connected with the belt pulley 5 of the speed regulating motor. The motor is adjusted to drive and adjust the rotation of the screw pushing device 3, and the upper part of the fuel hopper 2 is provided with a distributor 4, and the fuel hopper 2 is also provided with a cover plate. figure 1 The particles in the middle fuel cylinder and the fuel hopper represent biomass fuel, and the arrows represent the feeding direction.

[0018] According to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com