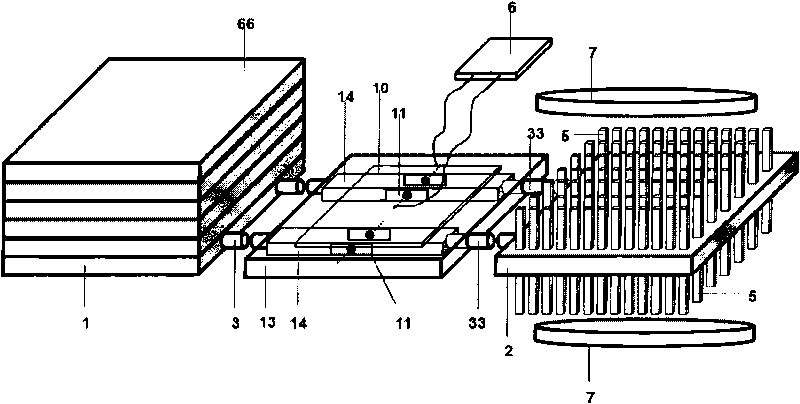

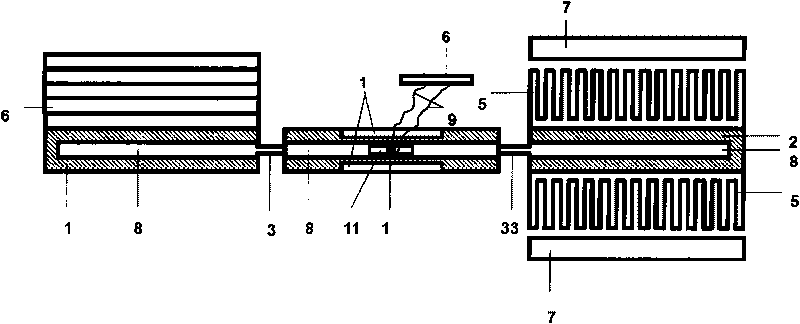

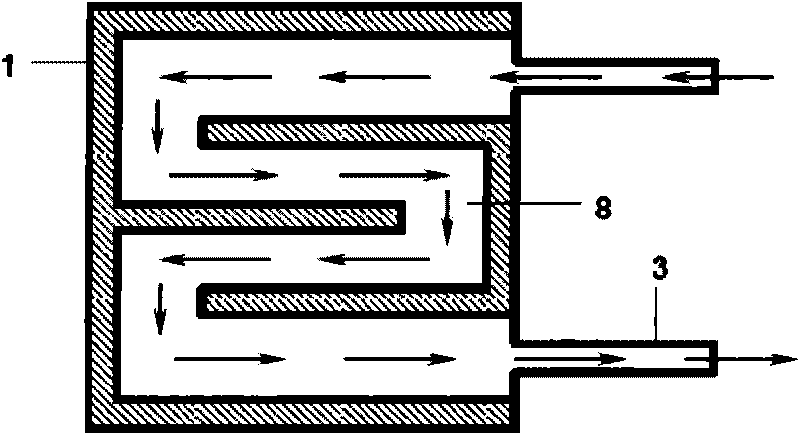

Liquid metal-cooling cascading semiconductor thermoelectric power generation device

A liquid metal cooling, thermoelectric power generation technology, applied in the direction of generators/motors, electrical components, etc., can solve the problems of inconvenience, low productivity, low efficiency, etc., and achieve compact structure, high efficiency, and low power consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] The liquid metal-cooled cascaded semiconductor thermoelectric power generation device of the present invention only needs to place the power generation module in a place with a high temperature such as a factory waste heat removal port or an automobile exhaust nozzle to realize power output, thereby satisfying all aspects. power demand. Of course, in the absence of a natural heat source, fuel such as various conventional fuels (oil, natural gas, biomass, etc.) can also be provided at the center of the semiconductor thermoelectric power generation module to provide a heat source, which can continuously provide electrical energy output. Generally, when there is sunlight, adjust the relative positions of the solar photovoltaic cell and the sunlight concentrator according to the characteristics of the local solar energy used by the user; thus, with the effect of solar energy, the temperature of the hot end of the semiconductor thermoelectric power generation module begins to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com