Method and filtering system for removing solid suspended particles from aquaculture system

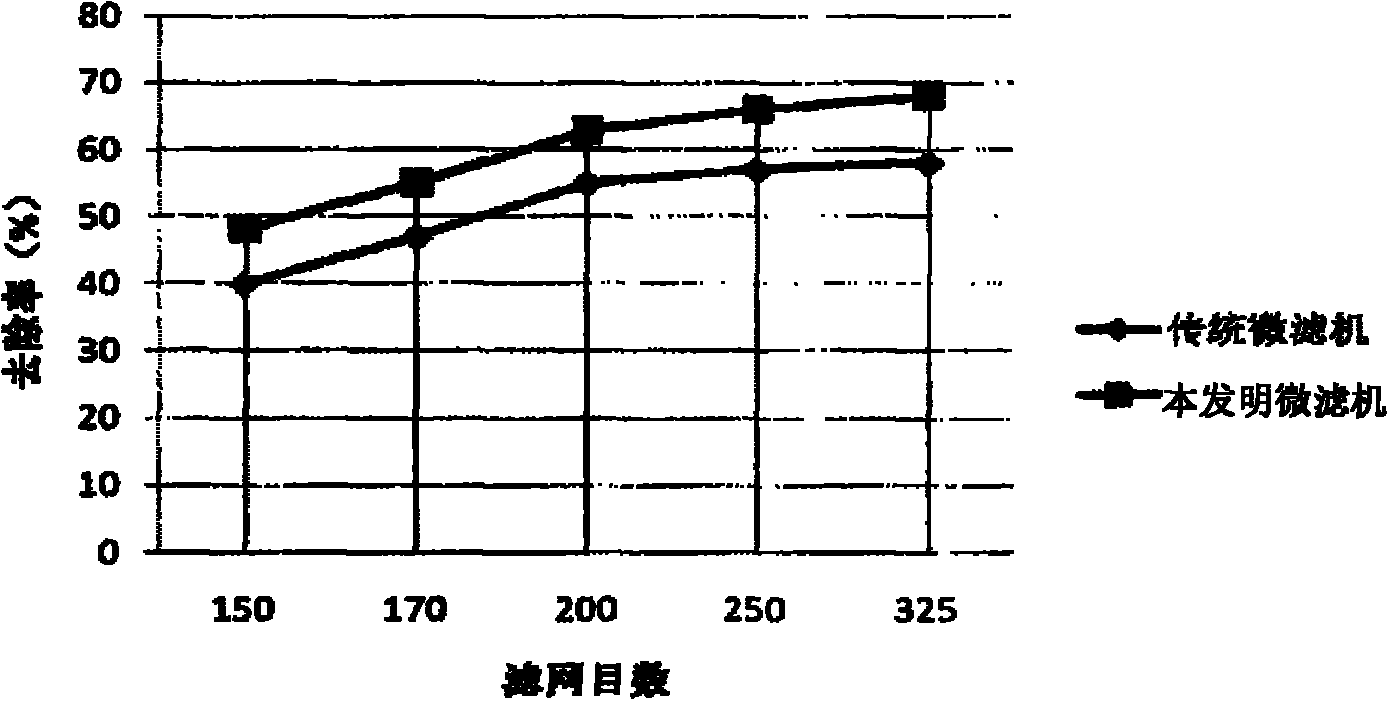

A technology of solid suspension and aquaculture, which is applied in fish farming, application, animal husbandry, etc. It can solve the problems of power consumption, poor filtering effect, and large water consumption of microfilters, so as to reduce energy consumption, prolong life, The effect of enhancing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

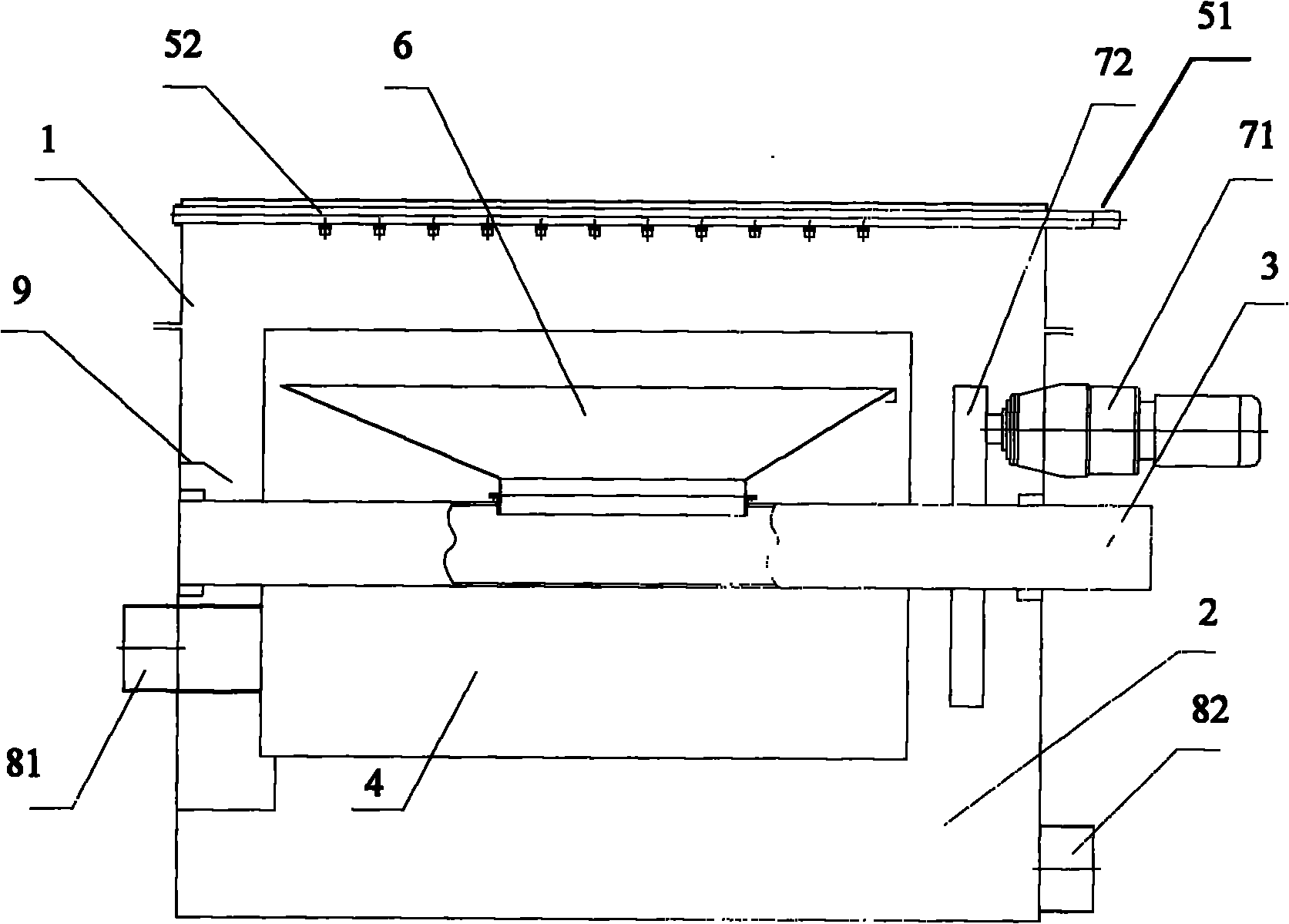

[0031] In this embodiment, the filtration system for removing suspended solids in the aquaculture system includes a microfilter and an automatic control device. figure 1 It is a structural schematic diagram of the microfiltration machine of this embodiment, which includes a machine cover 1, a box body 2, a central support shaft 3, a filter drum 4, a backwash pipe 51, a nozzle 52, and a backwash water pump (not shown) , collecting dirt hopper 6, time relay (not shown), motor (not shown), cycloidal pinwheel reducer 71, gear set 72, water inlet pipe 81 and drainpipe 82, main body material is stainless steel. The central support shaft 3 is a hollow non-rotating part, which is fixed in the box body 2. The filter drum 4 is rotatably connected with the central support shaft 3 through two sliding bearings, so that the filter drum 4 can be centered on the axis of the central support shaft 3. The center rotates, and the outer surface of the filter drum 4 is equipped with 3 pieces of fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com