Method for forging bearing support forge piece

A technology of forging and forging ratio, applied in the direction of manufacturing tools, engine components, furnace types, etc., can solve problems such as failure to meet standards, very high performance requirements for forgings, and inability to achieve localization, and achieve reliability improvement and meet technical requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

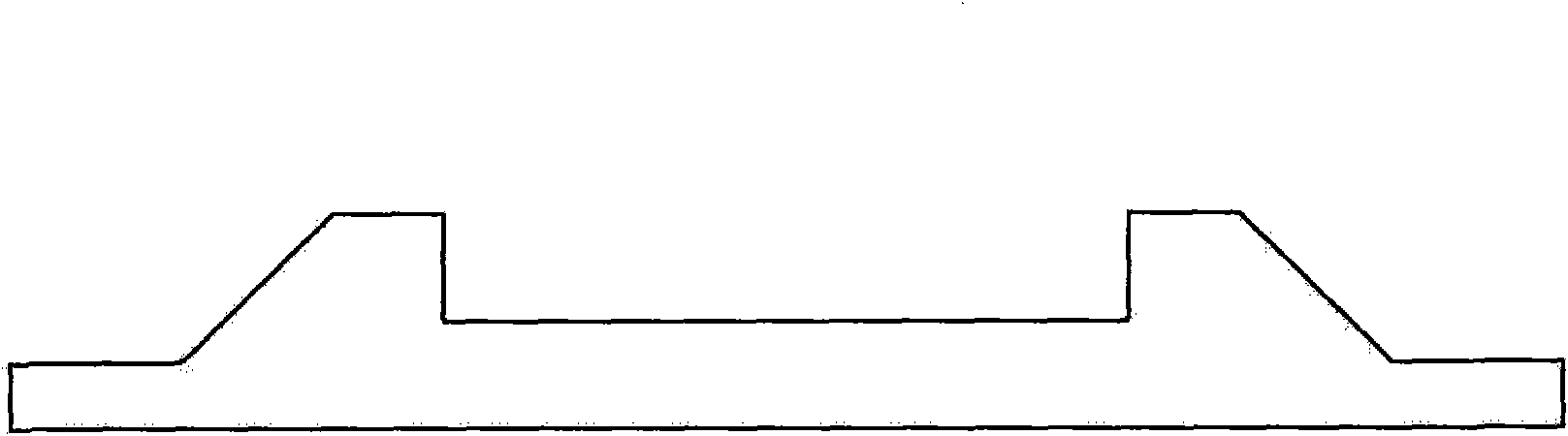

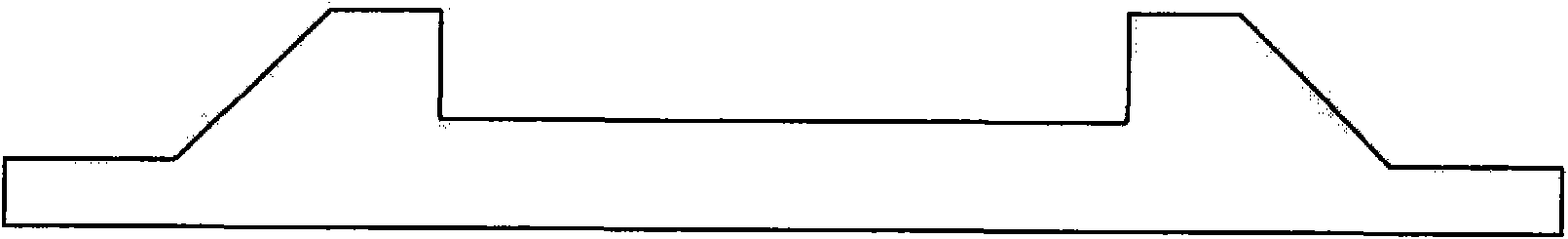

Image

Examples

Embodiment 1

[0032] Embodiment 1: the requirement of manufacturing process among the present embodiment is:

[0033] 1. Material selection:

[0034] Choose 24 "square ingot, 3670Kg / support, the chemical composition of this 24 " square ingot should meet the following regulations:

[0035] Trace ≤ C ≤ 0.22%, 0.10% ≤ Si ≤ 0.30%, 1.15% ≤ Mn ≤ 1.60%, Trace ≤ P ≤ 0.015%, Trace ≤ S ≤ 0.012%, 0.50% ≤ Ni ≤ 0.80%, Trace ≤Cr≤0.20%, 0.40%≤Mo≤0.60%, trace ≤V≤0.01%, trace ≤Cu≤0.10%, 0.01%≤Al≤0.04%, trace ≤Co≤0.03%, the balance is Fe and unavoidable impurities.

[0036] 2. Forging:

[0037] Cutting percentage of ingot head and ingot tail: 17% cut head and 8% cut tail of steel ingot.

[0038] a) Heat the steel ingot to 800°C, hold it for 4 hours, then heat it at 100°C / h to 1200°C, hold it for 2 hours, and pull out the billet.

[0039] b) Heating the workpiece to 1200° C., keeping it warm for 2 hours, and performing elongation-upsetting. The forging ratio of the upsetting and elongation process is 1....

Embodiment 2

[0054] Embodiment 2: the requirement of manufacturing process among the present embodiment is:

[0055] 1. Material selection:

[0056] Choose 24 "square ingot, 3670Kg / support, the chemical composition of this 24 " square ingot should meet the following regulations:

[0057] Trace ≤ C ≤ 0.22%, 0.10% ≤ Si ≤ 0.30%, 1.15% ≤ Mn ≤ 1.60%, Trace ≤ P ≤ 0.015%, Trace ≤ S ≤ 0.012%, 0.50% ≤ Ni ≤ 0.80%, Trace ≤Cr≤0.20%, 0.40%≤Mo≤0.60%, trace ≤V≤0.01%, trace ≤Cu≤0.10%, 0.01%≤Al≤0.04%, trace ≤Co≤0.03%, the balance is Fe and unavoidable impurities.

[0058] 2. Forging:

[0059] Cutting percentage of ingot head and ingot tail: 17% cut head and 8% cut tail of steel ingot.

[0060] f) Heat the steel ingot to 800°C, keep it warm for 4 hours, then heat it at 100°C / h to 1200°C, keep it warm for 2 hours, and pull out the billet.

[0061] g) Heating the workpiece to 1200° C., keeping it warm for 2 hours, and performing elongation-upsetting. The forging ratio of the upsetting and elongation pro...

Embodiment 3

[0076] Embodiment 3: the requirement of manufacturing process among the present embodiment is:

[0077] 1. Material selection:

[0078] Choose 24 "square ingot, 3670Kg / support, the chemical composition of this 24 " square ingot should meet the following regulations:

[0079] Trace ≤ C ≤ 0.22%, 0.10% ≤ Si ≤ 0.30%, 1.15% ≤ Mn ≤ 1.60%, Trace ≤ P ≤ 0.015%, Trace ≤ S ≤ 0.012%, 0.50% ≤ Ni ≤ 0.80%, Trace ≤Cr≤0.20%, 0.40%≤Mo≤0.60%, trace ≤V≤0.01%, trace ≤Cu≤0.10%, 0.01%≤Al≤0.04%, trace ≤Co≤0.03%, the balance is Fe and unavoidable impurities.

[0080] 2. Forging:

[0081] Cutting percentage of ingot head and ingot tail: 17% cut head and 8% cut tail of steel ingot.

[0082] k) Heat the steel ingot to 800°C, keep it warm for 4 hours, then heat it at 100°C / h to 1200°C, keep it warm for 2 hours, and pull out the billet.

[0083] l) Heating the workpiece to 1200° C., keeping it warm for 2 hours, and performing elongation-upsetting. The forging ratio of the upsetting and elongation pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com