CNC abrasive belt grinding machine of steam turbine blade

A technology for steam turbine blades and abrasive belt grinders, which is applied to abrasive belt grinders, grinding machines, grinding/polishing equipment, etc., can solve the problems of small adjustment, low transmission efficiency, and inconvenient adjustment, and achieve grinding quality assurance and grinding High efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

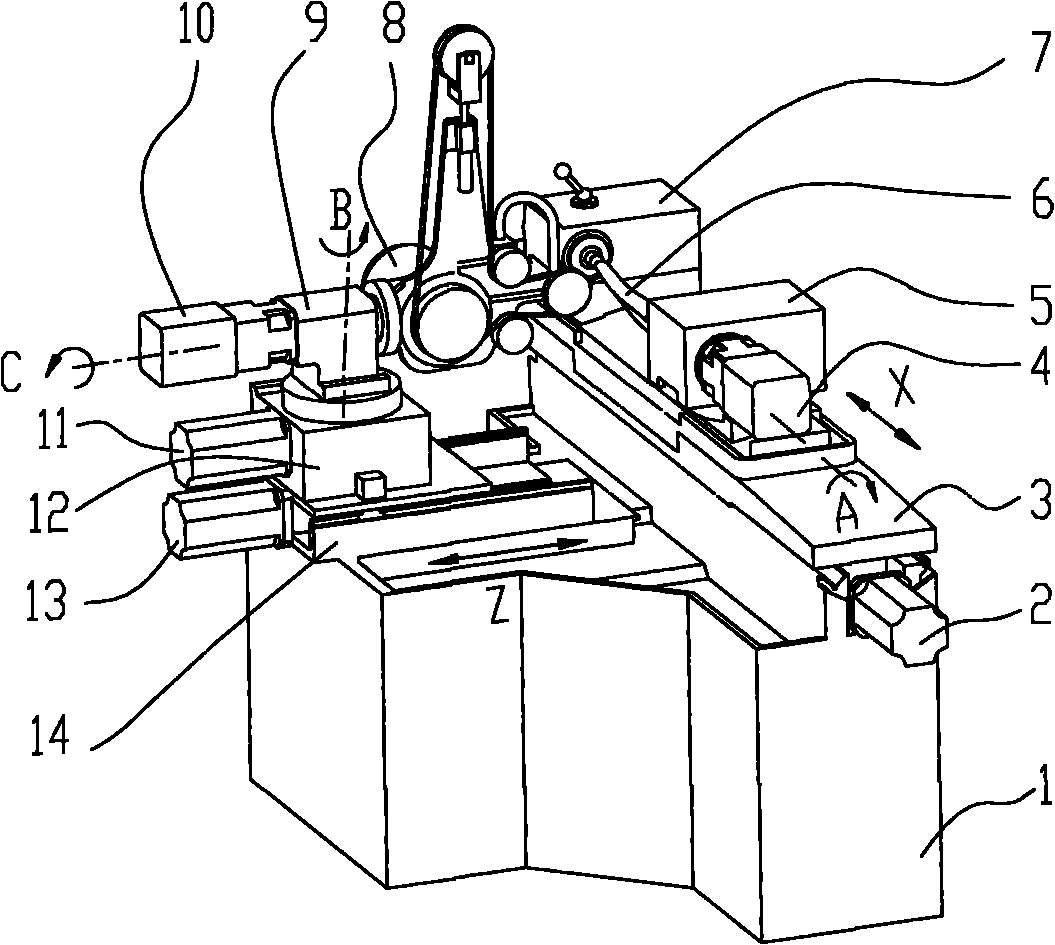

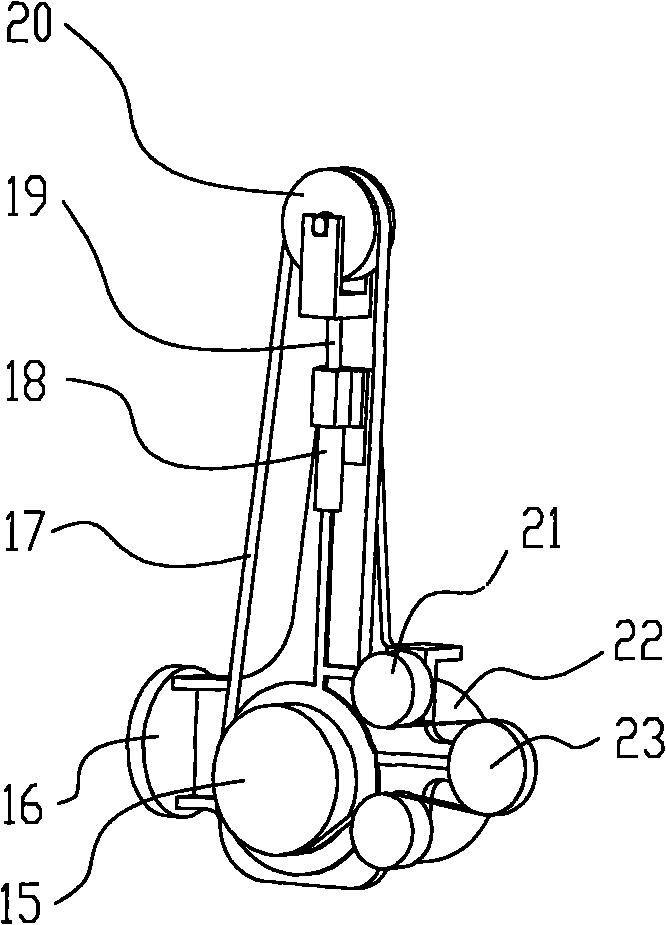

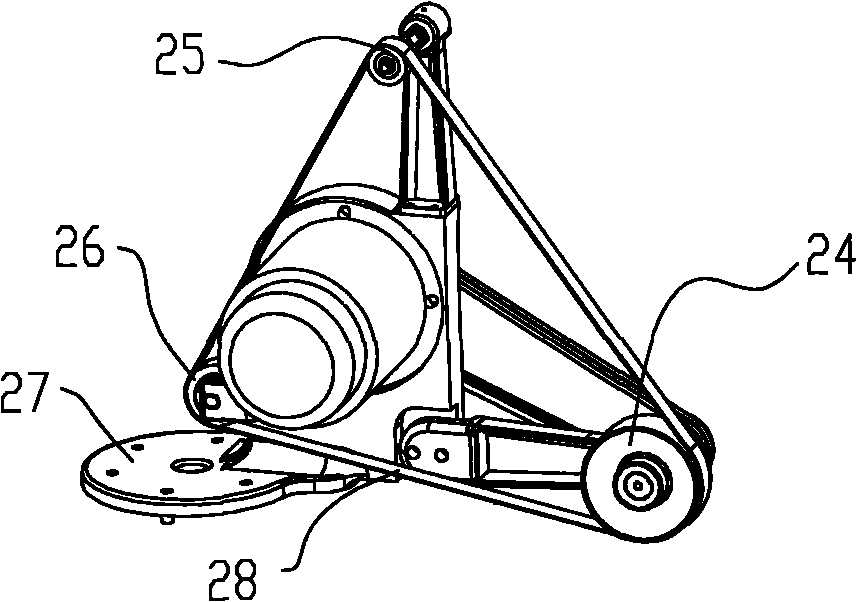

[0017] Such as figure 1 , 2 As shown, the present invention includes a bed 1 of a machine tool, a headstock 5 and a tailstock 7 for clamping and rotationally driving the blade 6 to be processed, an abrasive belt grinding head 8, and the headstock 5 is provided with a drive blade 6 for rotational movement A-axis servo motor 4, abrasive belt grinding head 8 includes contact wheel 23, and it also includes workbench device, abrasive belt grinder motion device and controller of bearing headstock 5 and tailstock 7; described workbench device includes The worktable 3 that moves in the X direction relative to the bed 1, and the X-axis servo motor 2 that drives the worktable 3 to perform linear reciprocating motion in the X direction; Drive the vertical turntable device for C axial rotation movement relative to the bed 1, carry the vertical turntable device and drive the horizontal turntable device for B axial rotation movement relative to the bed 1, and carry the horizontal turntabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com