Variable valve timing-phase controller

A phase controller and valve timing technology, applied in the direction of machine/engine, engine components, mechanical equipment, etc., can solve the problems of phase locking, the rotor cannot be rotated, the locking pin is stuck in the locking hole and cannot come out, etc. Achieve high thermal efficiency and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

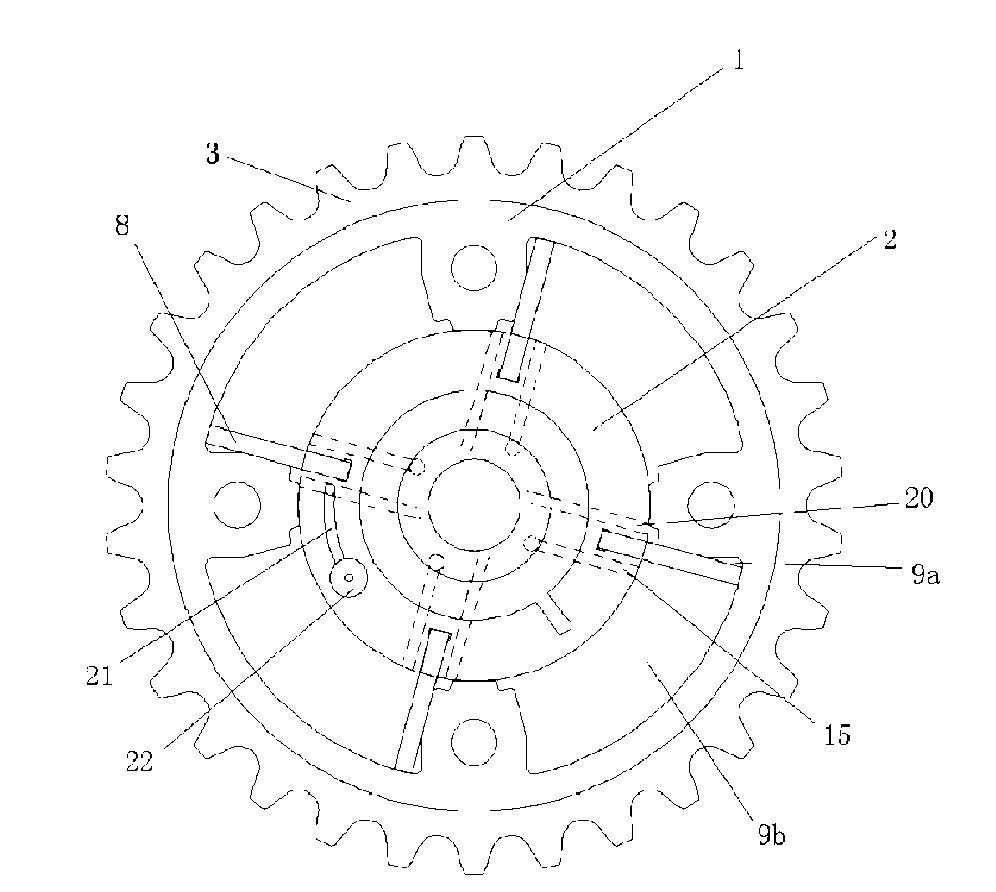

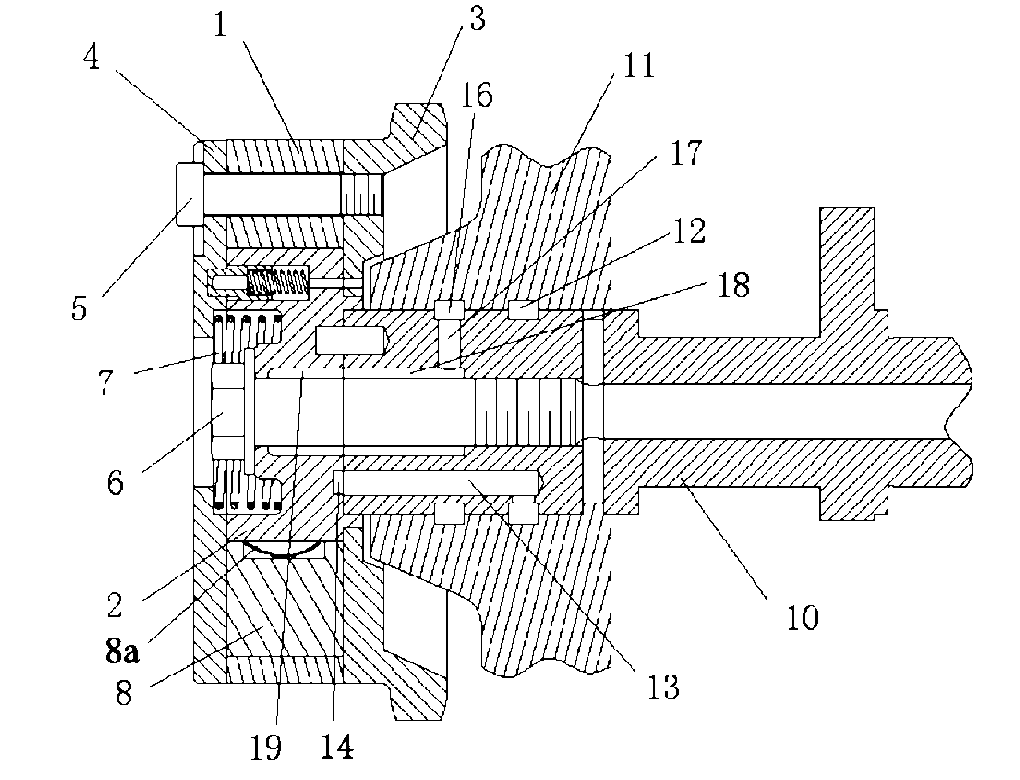

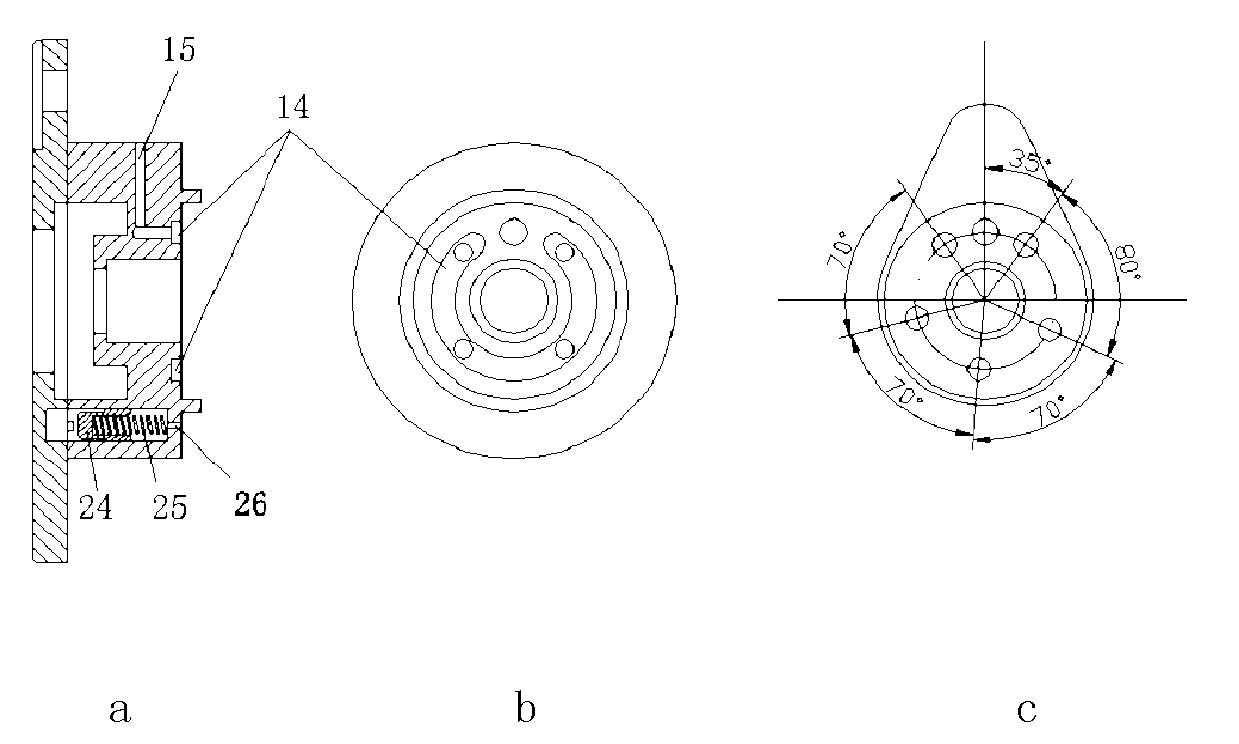

[0016] Such as figure 1 , figure 2 , image 3 As shown, this embodiment includes: housing 1, rotor 2, sprocket 3, front end cover 4, fastening bolt 5, center bolt 6, torsion return spring 7, blade 8, diaphragm spring 8a, advance cavity 9a, delay Cavity 9b, camshaft 10, first lock pin oil passage 21, second lock pin oil passage 22, lock pin 24, lock pin spring 25 and lock pin oil drain hole 26, wherein: rotor 2, cam The shaft 10 is fixed by the central bolt 6, the front cover 4, the housing 1 and the sprocket 3 are fixed by the fastening bolt 5, the blade 8 is fixed around the rotor 2, and there is a diaphragm s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com