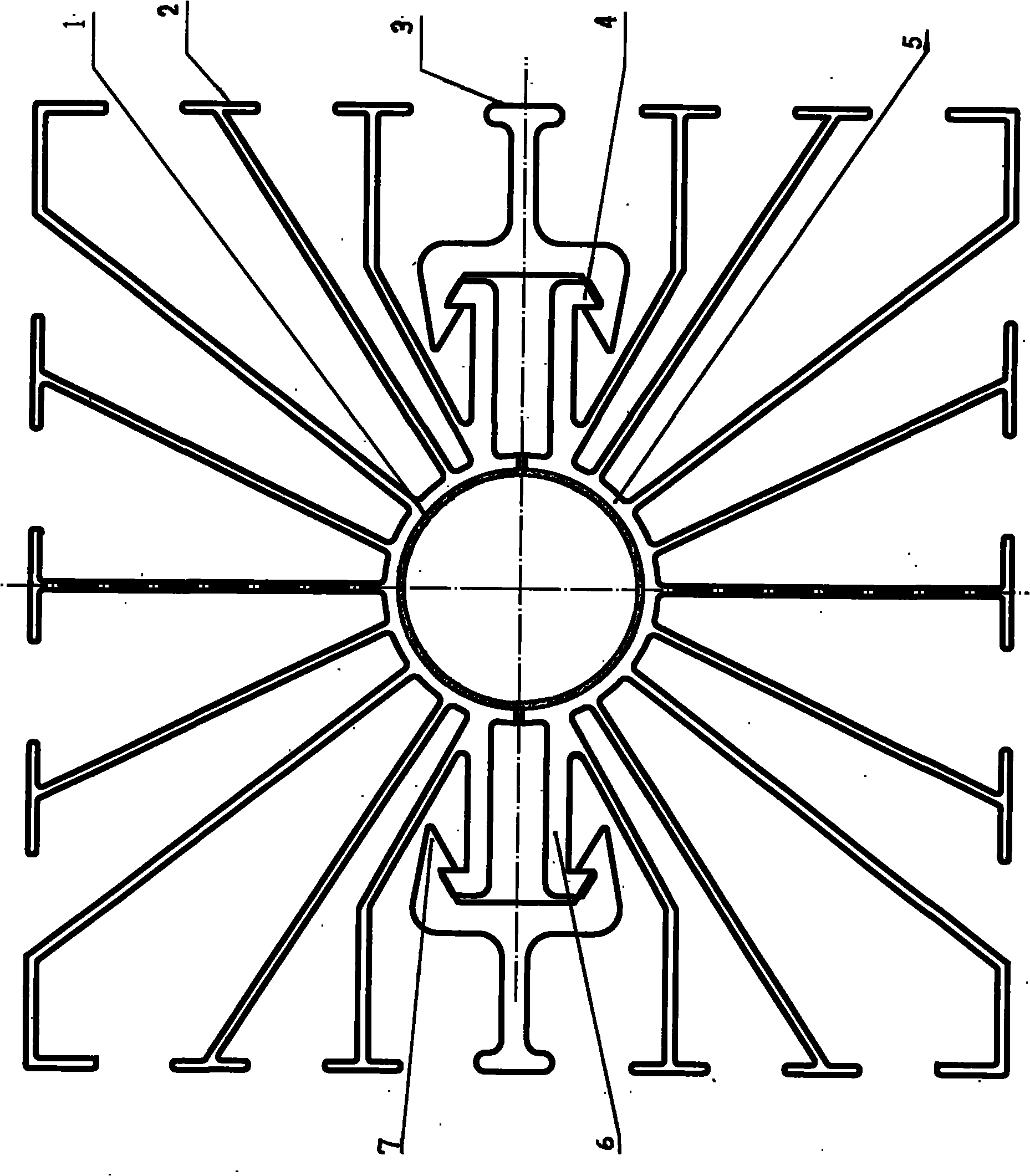

Modular stainless steel aluminum alloy radiator and manufacturing method thereof

A stainless steel radiator technology, applied in the field of heating radiators, can solve the problems of small heat dissipation area, low heat dissipation efficiency, and limited service life, and achieve the effect of simple manufacturing process, high heat dissipation efficiency and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] specific implementation plan

[0021] The vertical water pipe 1 has a diameter of 19mm and a wall thickness of 0.6mm. The header pipe has a diameter of 40mm and a wall thickness of 0.8mm. It is made into a radiator skeleton through high-frequency brazing, and the outer buckle is a special semicircular radial aluminum alloy with a self-locking device. Radiating fins, upper and lower installation of cooling covers, decorative panels (decorative installation only), deflectors, etc. First, the vertical water pipe 1 and the header pipe are brazed to form by high-frequency welding machine, and then the central semicircular pipe 5 of the heat dissipation wing is buckled on the vertical water pipe 1, and a lock bar 3 is buckled in a natural state, and the heat dissipation fin is adjusted. position, use a press to press in another lock bar 3, and fix the cooling wing profile on the vertical water pipe 1.

[0022] During the welding process, automatic high-frequency welding equi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com