Interconnected line failure detection method

A detection method and interconnection line technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of reduced detection efficiency, destructiveness, complicated process, etc., and achieve improved efficiency, positioning accuracy, and detection speed Fast and easy results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

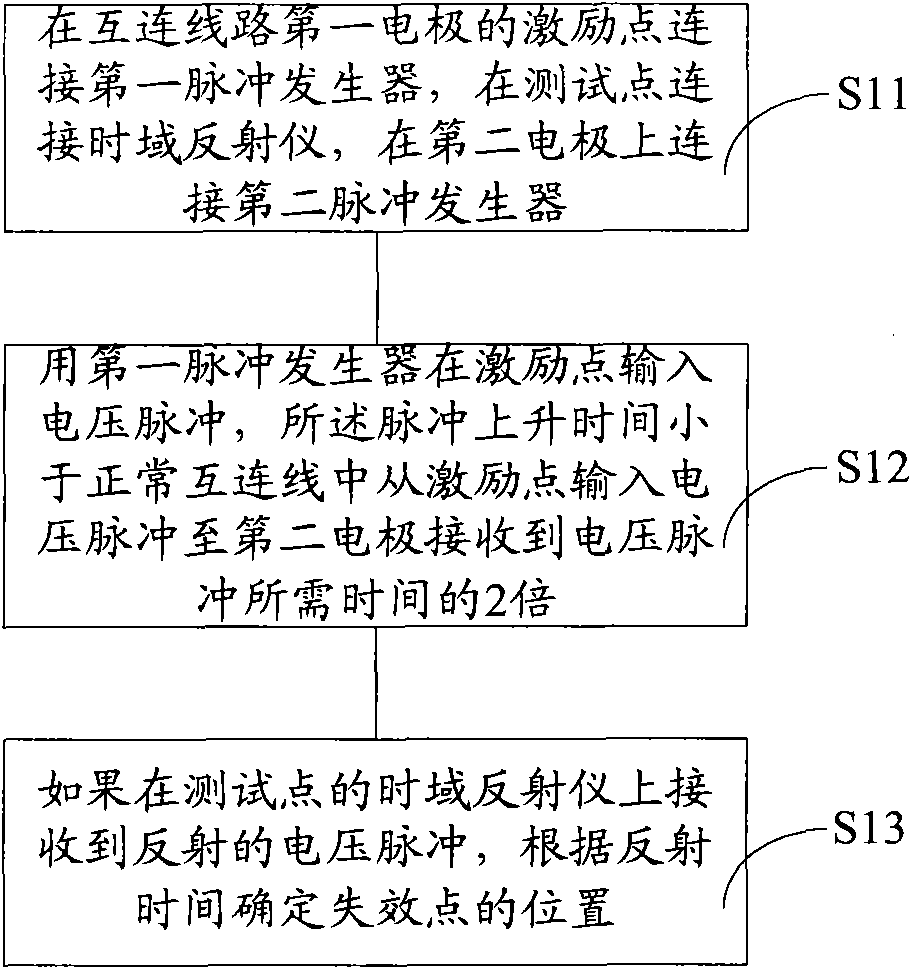

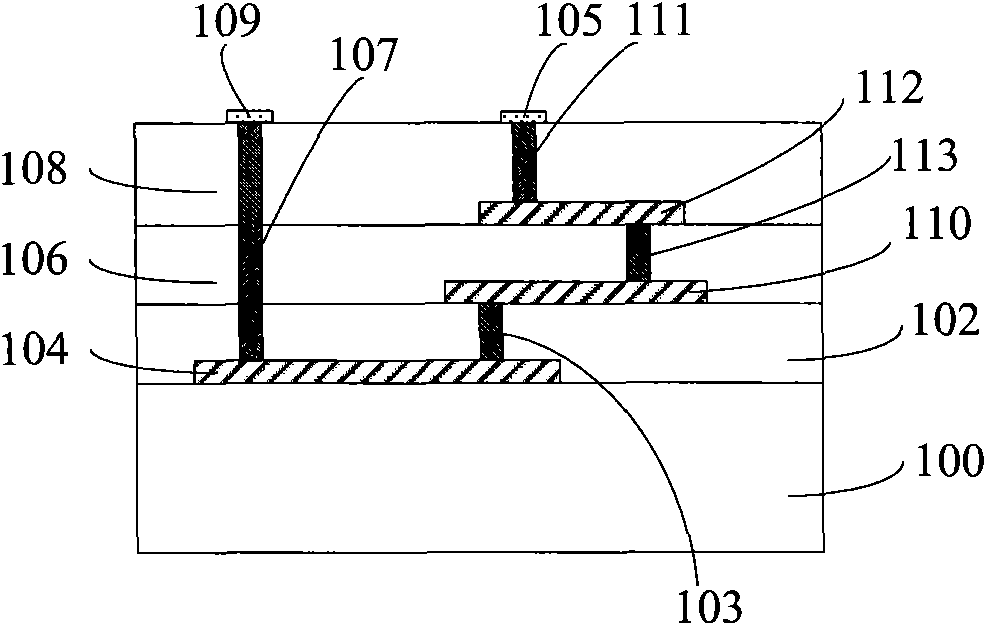

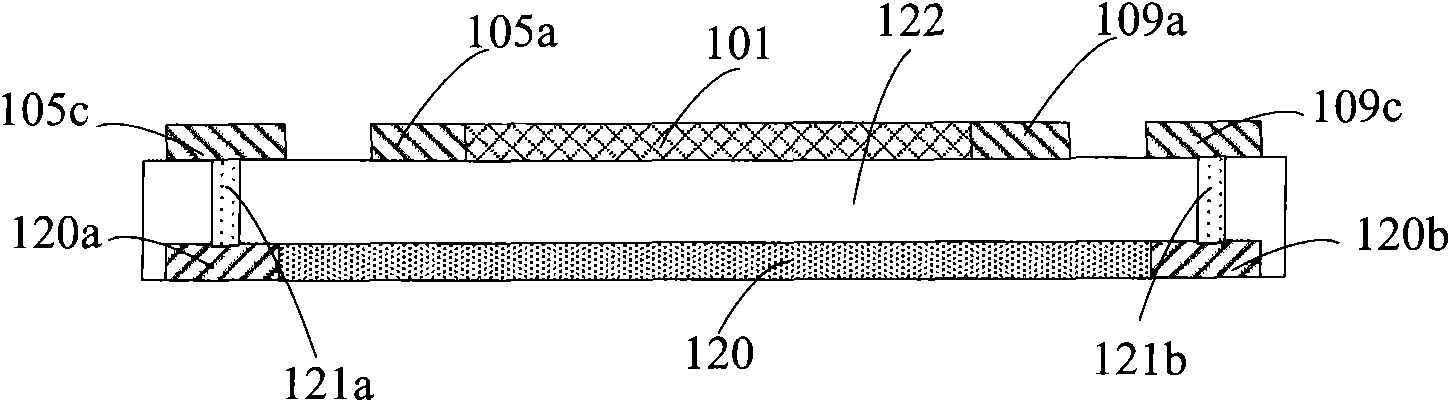

[0022] In the prior art, the failure location is usually determined by cutting the section of the failed semiconductor device with a focused ion beam until the failure point is exposed. The process is complicated and the detection efficiency is low. In the present invention, the excitation point of the first electrode of the interconnect circuit is connected to the first pulse generator, and a voltage pulse is input. If the interconnection is normal, i.e. not open, open or short, a voltage pulse can be received on the second pulse generator at the second electrode of the interconnect; and when the interconnect is open, open or short , the voltage pulse cannot be transmitted to the second pulse generator of the second electrode, and the voltage pulse will be reflected back to the time domain reflectometer at the test point of the first electrode in an open circuit, open circuit or short circuit, and the voltage pulse will be reflected from the launch to the back The time requir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impedance | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com