Digital hydraulic extruder speed control system and method

A technology of speed control and extruder, applied in the control equipment of metal extrusion, metal extrusion, manufacturing tools, etc., can solve the problems of being susceptible to interference signals in harsh environments, low precision, and easy to be interfered by the outside world. Achieve the effect of improving anti-interference ability and reliability, improving control accuracy, and simple and clear structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

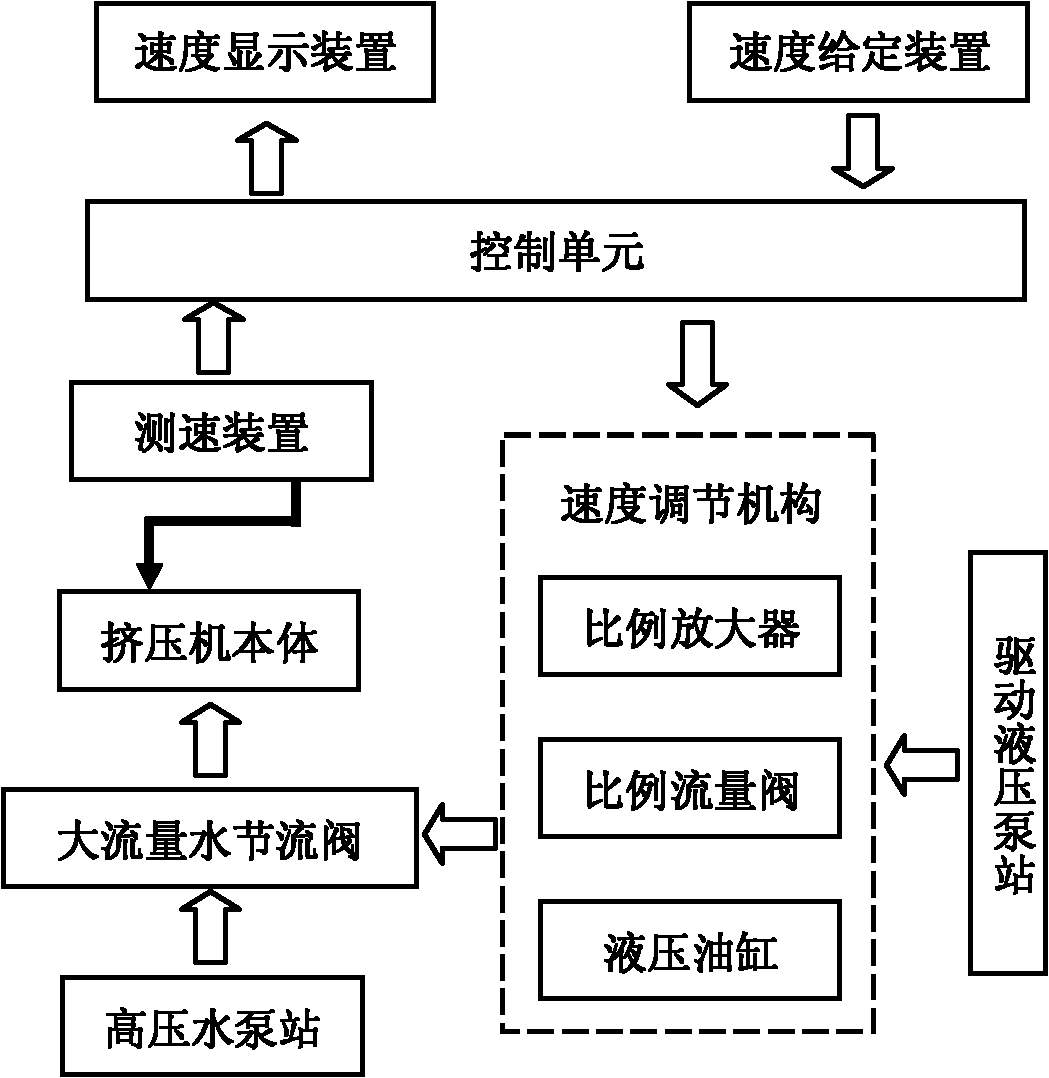

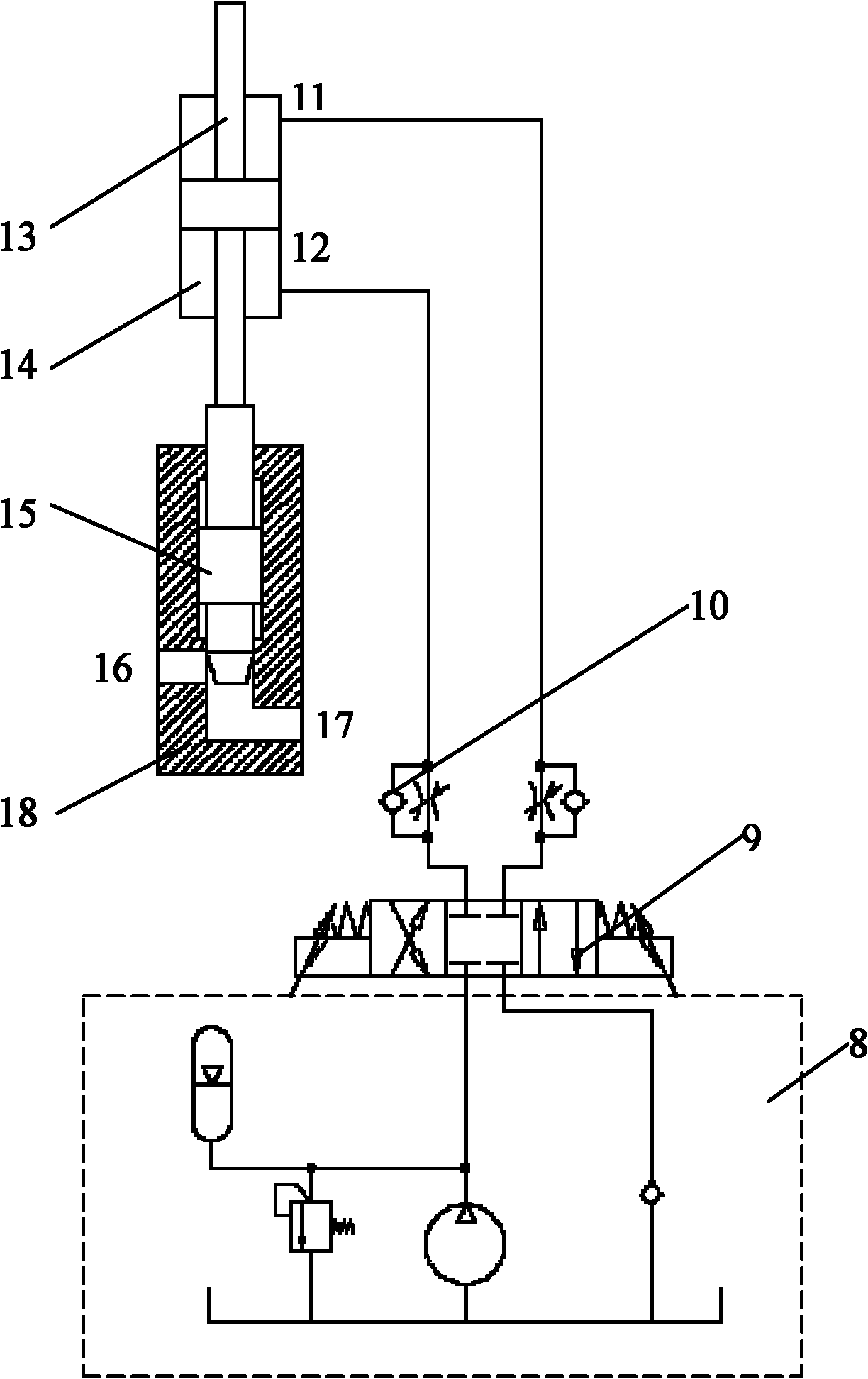

[0037] A speed control system for a digital large-scale hydraulic extruder includes: a speed setting device, a speed measuring device, a control unit, and a speed regulating mechanism. The control unit compares the actual speed measured by the speed measuring device with the speed given by the speed setting device, and obtains the speed control execution signal and outputs it to the speed adjustment mechanism. The speed adjustment mechanism adjusts the water throttle valve through the "oil control water" method. The opening of the spool realizes the closed-loop control of the extrusion speed of the hydraulic extrusion machine.

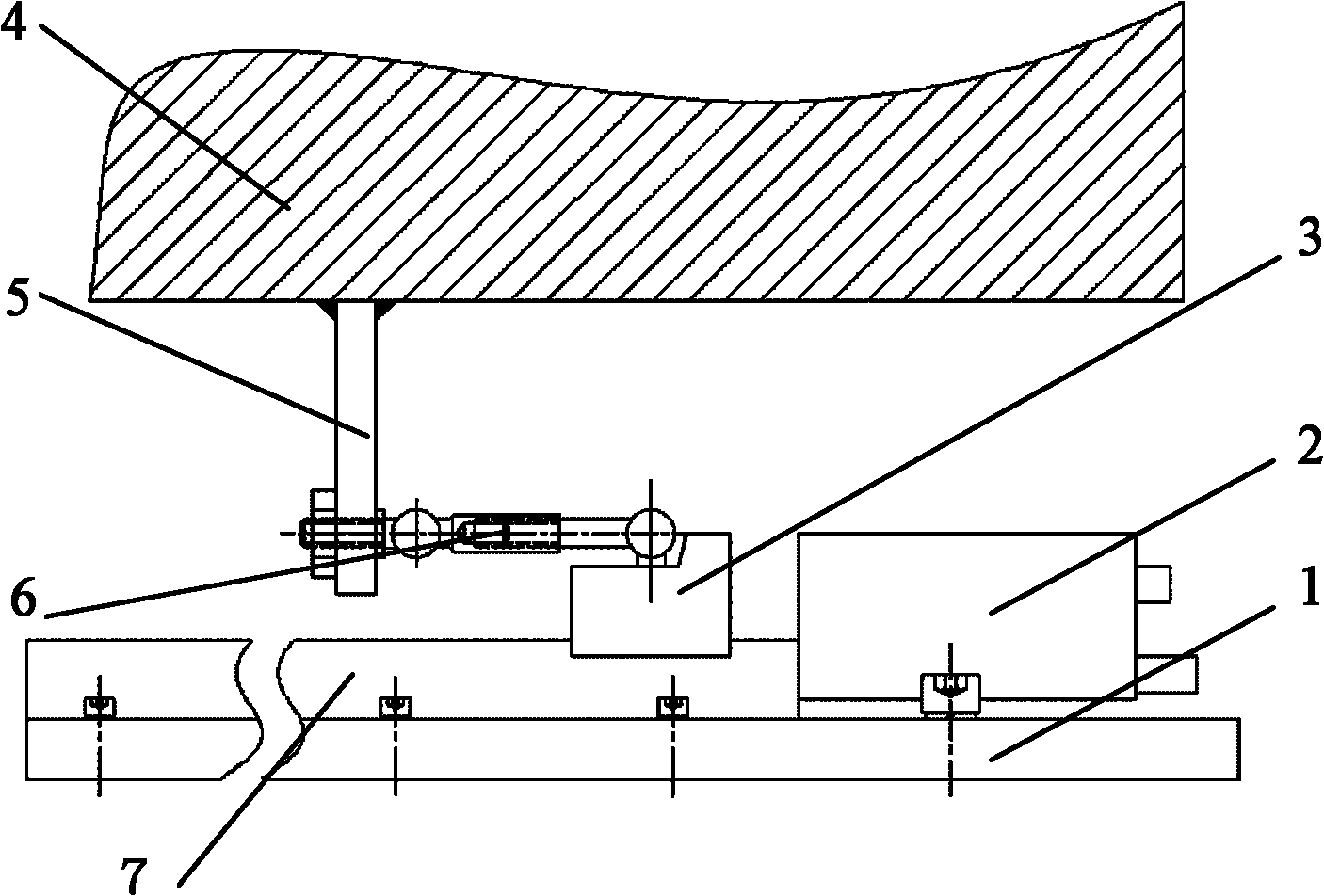

[0038] figure 1 Describes the overall structure of the present invention—a speed control system for a large hydraulic extruder: the system includes: a speed setting device, a speed measuring device, a control unit, a speed adjustment mechanism, etc., and the functions of each part are briefly described as follows:

[0039] Speed setting device: It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com